High-power polarization-maintaining optical fiber and preparation method thereof

A high-power, optical fiber technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problem of low output power of polarization-maintaining optical fiber, improve heat transfer efficiency, reduce viscosity difference and linear expansion coefficient difference, increase pump The effect of Puguang's input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

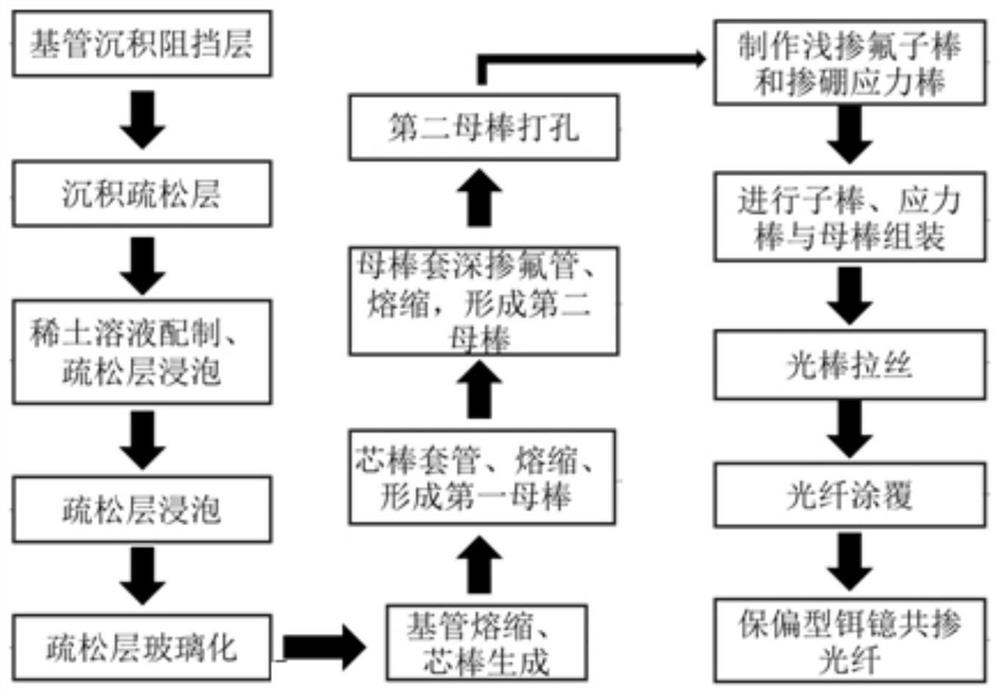

[0049] Such as figure 1 As shown, the preparation process of the biasing fiber in this embodiment is as figure 1 As shown, in order to facilitate understanding, the preparation process of the introduction of the branched three-clad 镱-blended optical fiber having a circular cross section is taken as an example.

[0050] The first step: First, the barrier layer is deposited in the inner wall of the base pipe, and the size of the outer diameter of 25 to 35 mm, the wall thickness is 2.5 to 3.5 mm, and the fluctuation value of the outer diameter of the base tube and the wall thickness is required to be 2 SF 6 Gas, polish it in the inner surface, the polishing time is 5 ~ 10 min; after design, deposit the barrier layer, into the base tube into SiCl 4 (Traffic: 200 ~ 300sccm) and O 2 (Flow: 1200sccm), sf 6 (Flow: 500 ~ 600sccm) The deposition temperature is controlled at 1700 to 1750 ° C, and the deposition barrier layer is controlled at 0.2 to 0.3 mm, and the glass transition is perfo...

Embodiment 2

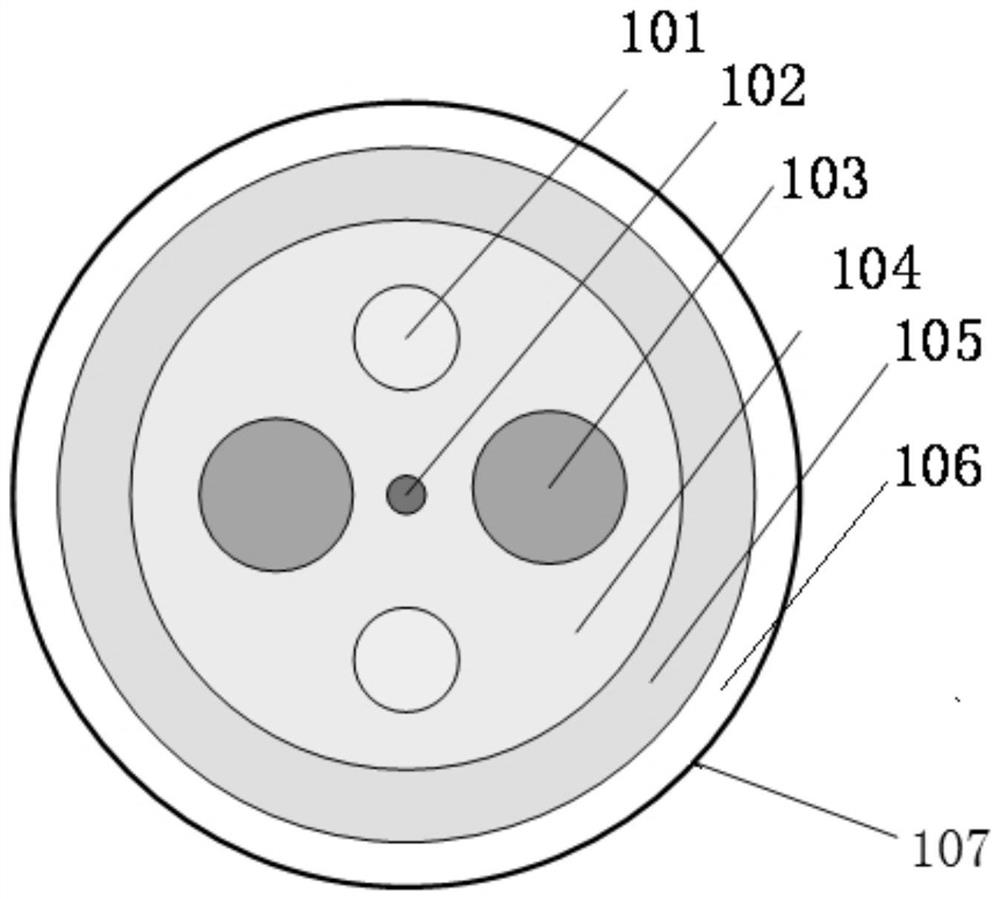

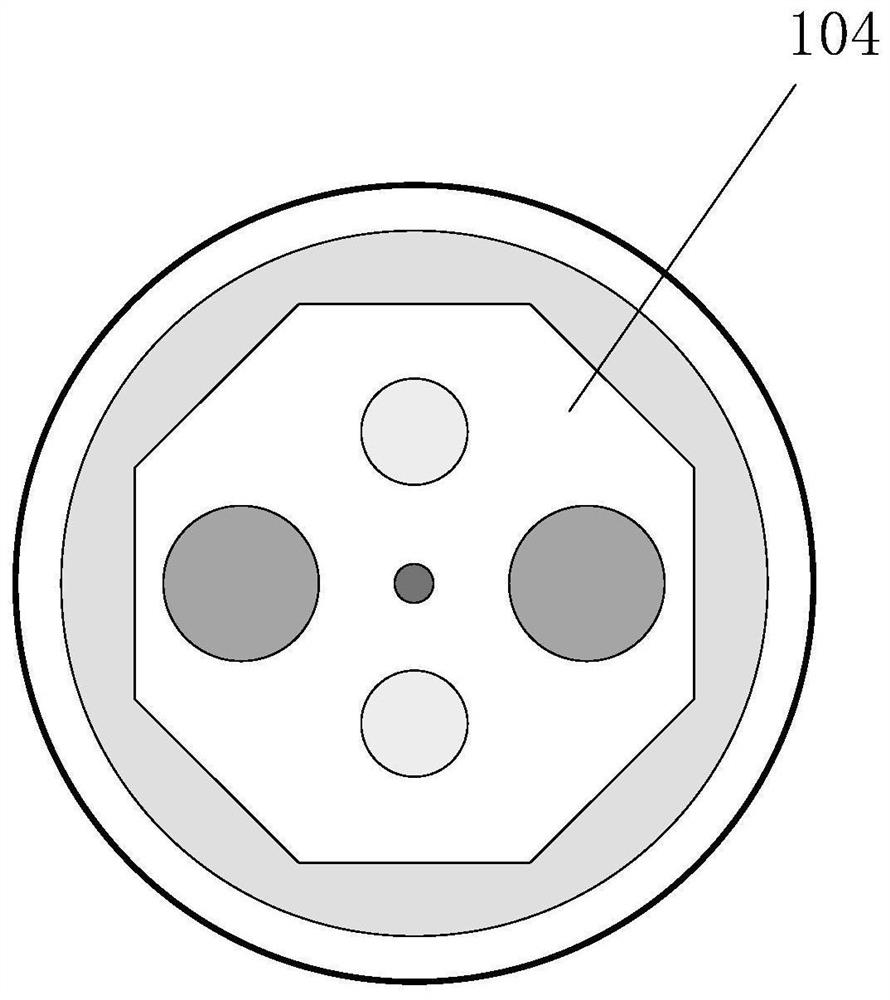

[0062] Example 1 The cross-sectional structure of the obtained high-power polarizing fiber was inwardly included inwardly including the core 102, the first cladding layer 104, the second cladding 105, the outer clad layer 106, and the outer coating 107.

[0063] The core 102 is 0.08%, and the diameter D1 is 25 μm relative to the purity difference of the purity.

[0064] The first cladding layer 104 is filled with two shallow fluorine-based rods along the core 102 to form a fluorine region (101), and the refractive index difference Δ2 relative to the purity quartz is -0.08%, fluor fluor fluor region. 101) Diameter D2 is 80 μm.

[0065] The first cladding layer 104 also fills two blending strain stress rods along the core 102 to constitute a stress zone 103, and the refractive index difference Δ3 with respect to the purity of the purity is -0.6%, the stress zone (103) diameter. D3 is 110 μm.

[0066] The symmetrical axis of the fluorine region 101 and the symmetric axis of the stres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com