Building elevator

A hoist and building technology, applied in the direction of cranes, shafts and bearings, etc., can solve the problems of insufficient technology and reduce the service life of steel wire ropes, and achieve the effects of avoiding frictional heat generation damage, reducing contact area, and reducing thermal friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

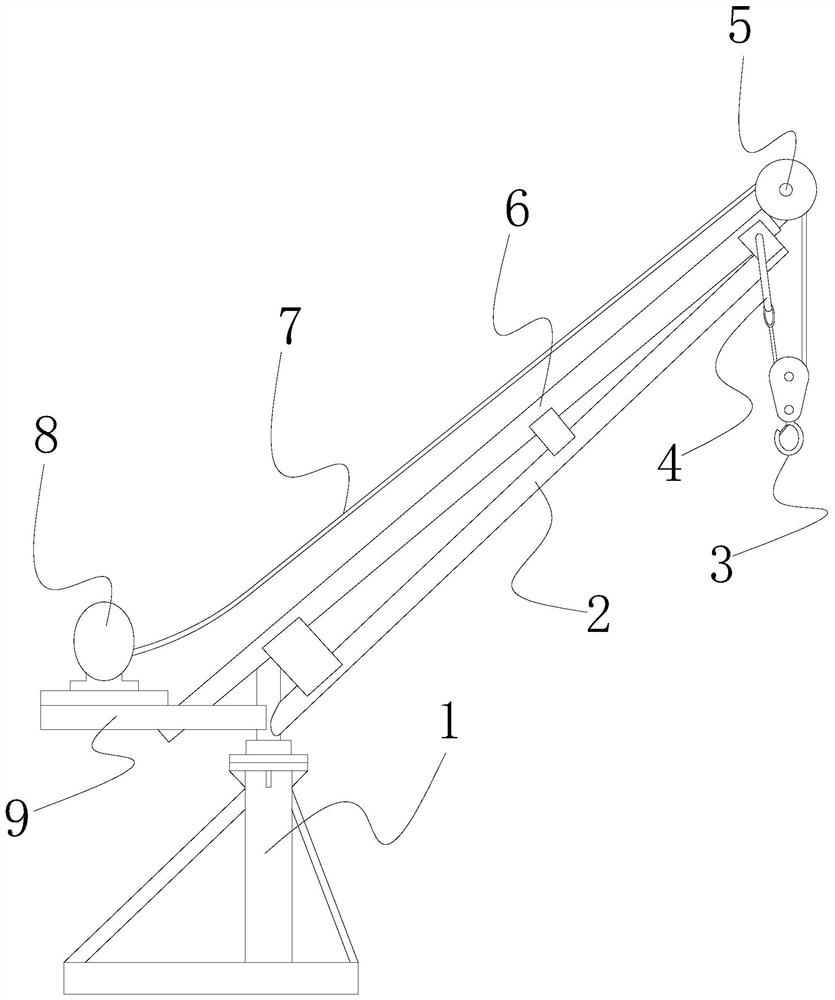

[0028] See Figure 1-5 The present invention provides a technical solution for a building hoist: its structure includes a rotating support table 1, a line 1 link 2, a sliding hook 3, a hook 4, a guide wheel 5, a line 6, a wire rope 7, and improvement The device 8, the support plate 9, the rotating support table 1 fixedly connected to a line 1 link 2, a second link 6, and the line No. 1 link 2 is located below the second link 6 and the outer side is connected by a connecting plate. Together, the top of the second link 6 is attached, and the rotating support table 1 is vertically connected to one end of the guide wheel 5, and the support plate 9 is mechanically connected to the lifting device 8, The lifting device 8 is connected to one end of the wire rope 7, and the other end of the wire rope 7 is coupled to the hook 4 through the guide wheel 5.

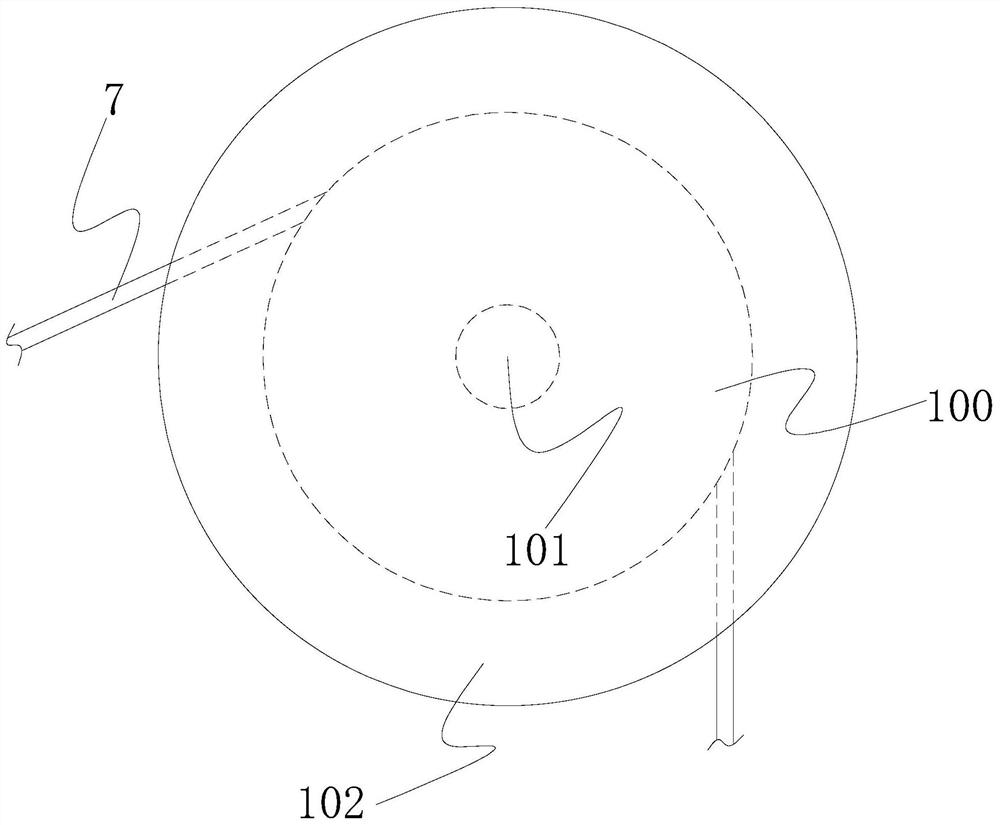

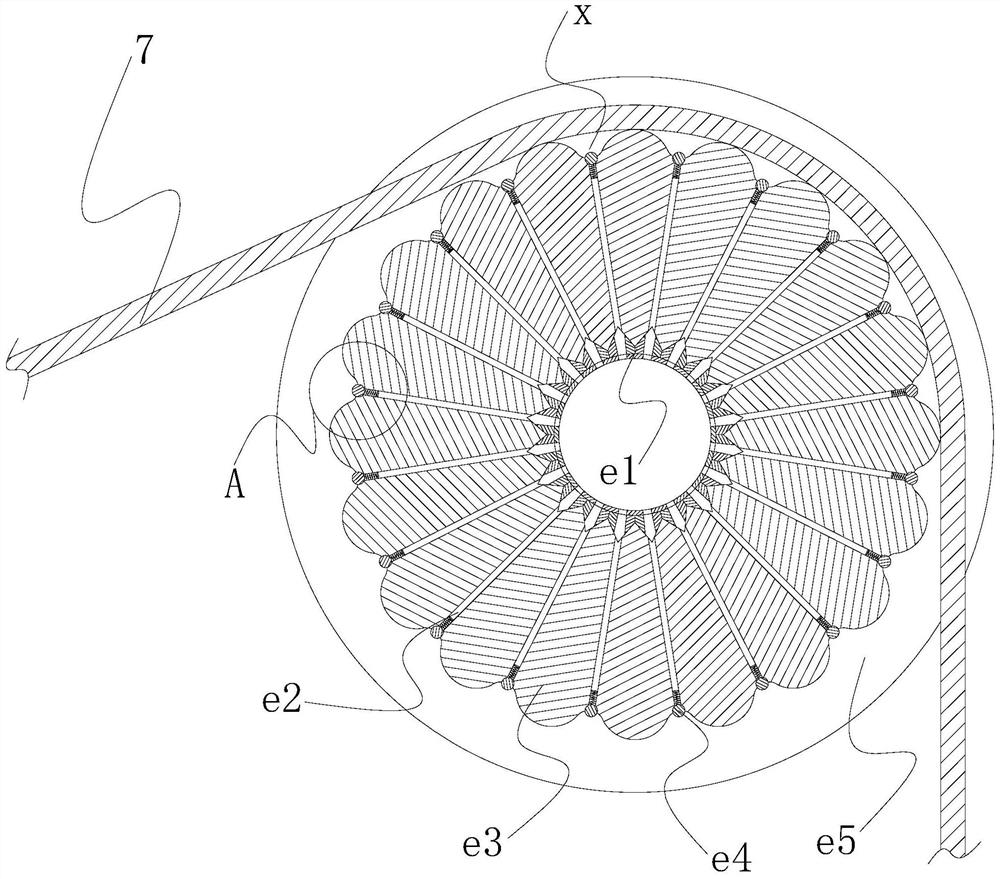

[0029] The guide wheel 5 includes a wheel 100, a rotating shaft 101, a heat sink 102, and the rotating shaft 101 runs through the wheel ...

Embodiment 2

[0038] See Figure 1-7 The present invention provides a technical solution for a building hoist: its structure includes a rotating support table 1, a line 1 link 2, a sliding hook 3, a hook 4, a guide wheel 5, a line 6, a wire rope 7, and improvement The device 8, the support plate 9, the rotating support table 1 fixedly connected to a line 1 link 2, a second link 6, and the line No. 1 link 2 is located below the second link 6 and the outer side is connected by a connecting plate. Together, the top of the second link 6 is attached, and the rotating support table 1 is vertically connected to one end of the guide wheel 5, and the support plate 9 is mechanically connected to the lifting device 8, The lifting device 8 is connected to one end of the wire rope 7, and the other end of the wire rope 7 is coupled to the hook 4 through the guide wheel 5.

[0039] The guide wheel 5 includes a wheel 100, a rotating shaft 101, a heat sink 102, and the rotating shaft 101 runs through the wheel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com