Material mixing device before freeze-dried powder preparation

A technology for material mixing and freeze-drying powder, which is applied to mixers with rotating containers, mixers, mixing methods, etc., can solve problems such as low efficiency, inability to be suitable for continuous production, and no application method for the proportioning of gravity sensors. Achieve the effect of improving the effect, optimizing the effect of the feeding operation, and ensuring the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

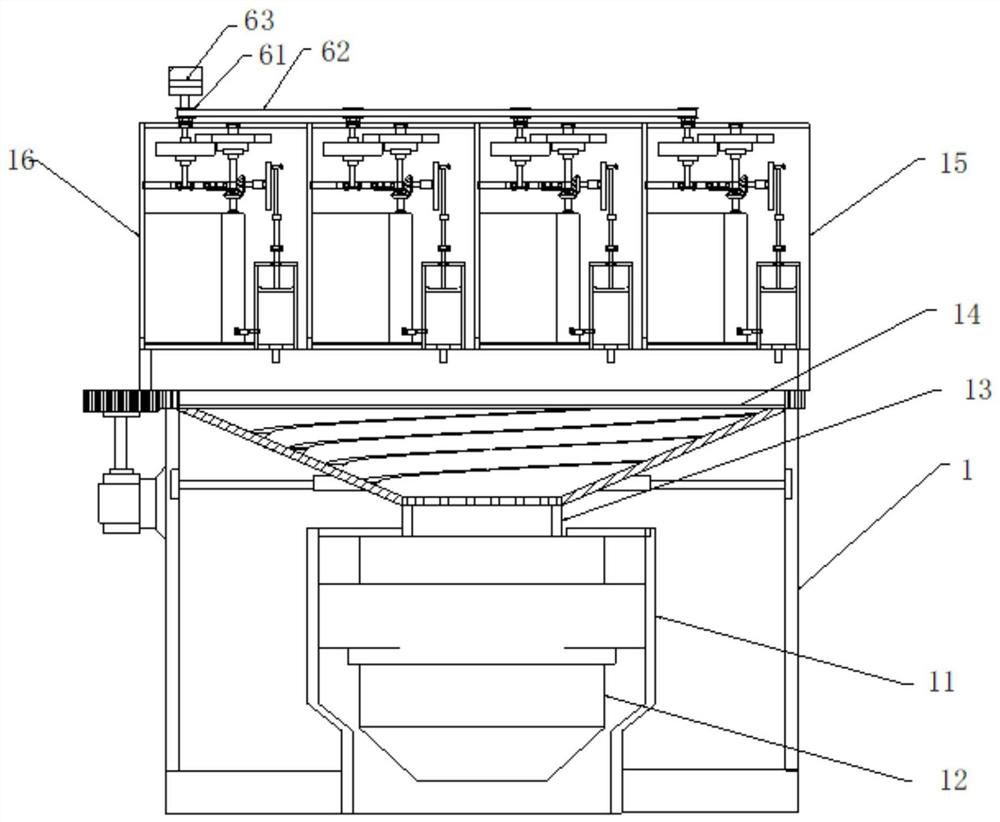

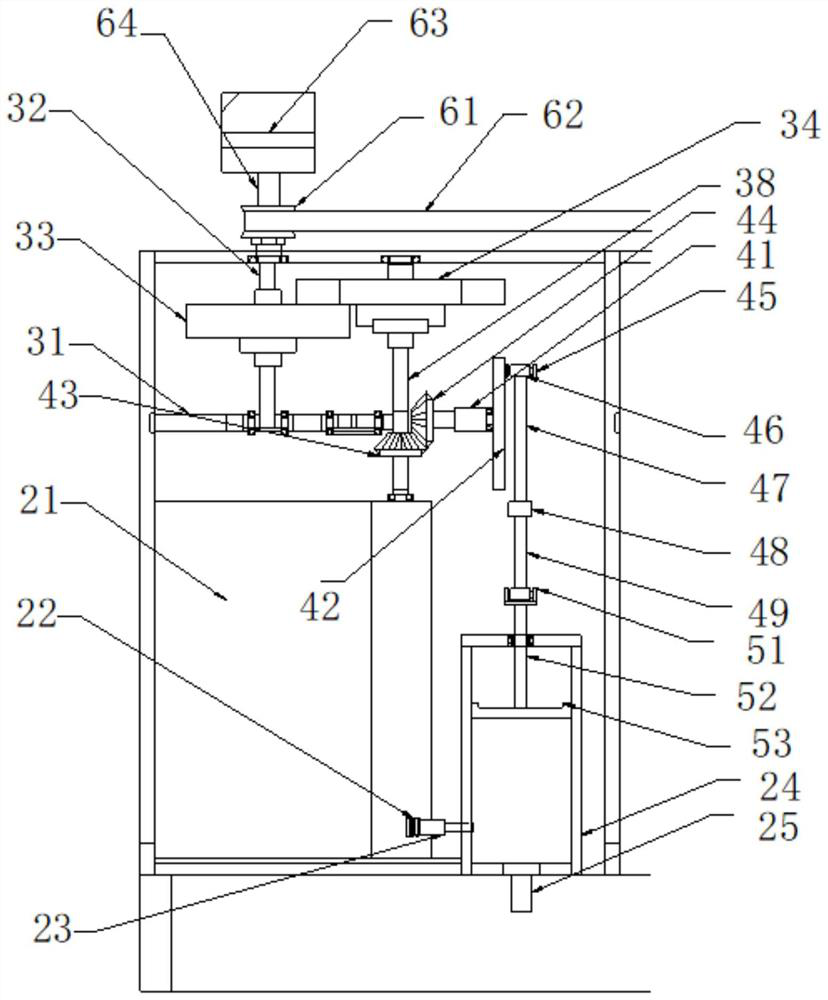

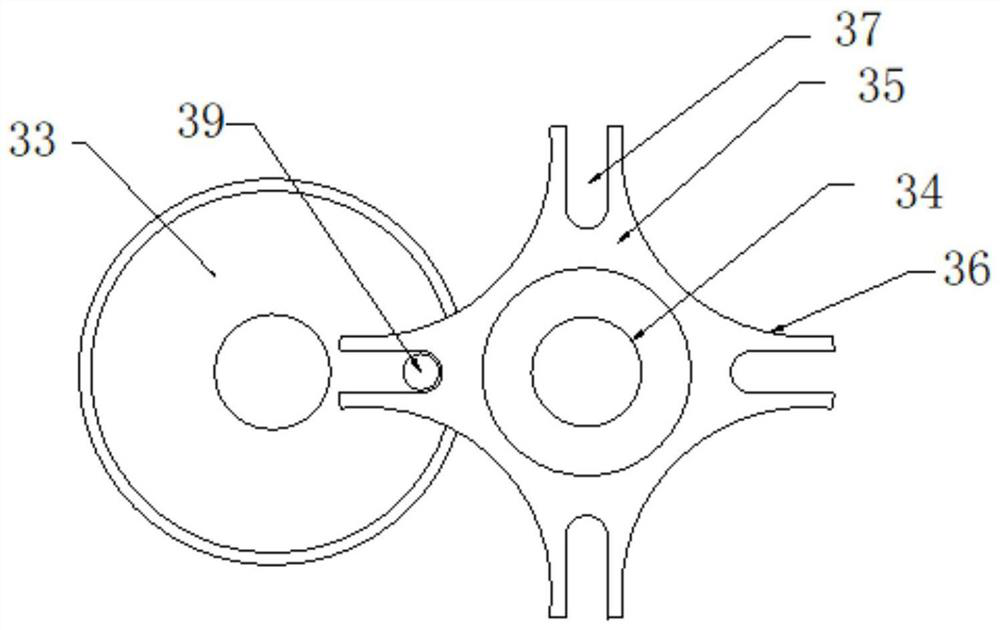

[0026] see figure 1 and image 3 , a material mixing device before the preparation of freeze-dried powder, comprising a material rack 1, the inner cavity of the material rack 1 is provided with an equipment rack 11, and a preparation kettle 12 is installed on the equipment rack 11, and the top of the preparation kettle 12 is A feeding end 13 is provided, and a mixing chamber 14 is arranged above the feeding end 13, and the top of the mixing chamber 14 is provided with a batching rack 15, and the batching rack 15 is provided with several batching racks 16 . The inner chamber of the batching support 16 is provided with a raw material box 21 and a turnover drum 24, and the bottom of the raw material box 21 is provided with a discharge head 22, and the discharge head 22 is connected to the turnover drum 24 through a feeding pipeline 23, A feed pipe 25 is installed at the discharge end of the turnover drum 24 , and the feed pipe 25 is located directly above the mixing chamber 14 ...

Embodiment 2

[0032] see figure 1 and Figure 4 , this embodiment is a further optimization of Embodiment 1, on the basis of which, the main body of the mixing chamber 14 is a mixing hopper 71, the mixing hopper 71 is a bucket-shaped structure, and the inner cavity of the mixing hopper 71 is provided with The spiral groove 72, the bottom cone angle of the mixing hopper 71 is provided with a blanking screen 73, and the blanking screen 73 is connected to the feeding end of the preparation kettle 12 through a connecting pipe 74. The material rack 1 is provided with a horizontal support 81, and the horizontal support 81 is provided with a limit support ring 82. The mixing hopper 71 is movable and installed on the limit support ring 82. The mixing hopper 71 An outer hoop 75 is arranged on the outer edge, the outer surface of the outer hoop 75 is provided with an outer tooth pattern 76, and the outer side of the material rack 1 is provided with a motor frame 77, and the motor frame 77 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com