Preparation process of textile high-lubricating oil agent

A preparation process and a technology for lubricating oil, applied in the field of lubricating oil, can solve the problems of uneven stirring of oil at the bottom, large energy consumption, long stirring time, etc., and achieve the effects of reducing energy consumption, ensuring uniformity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

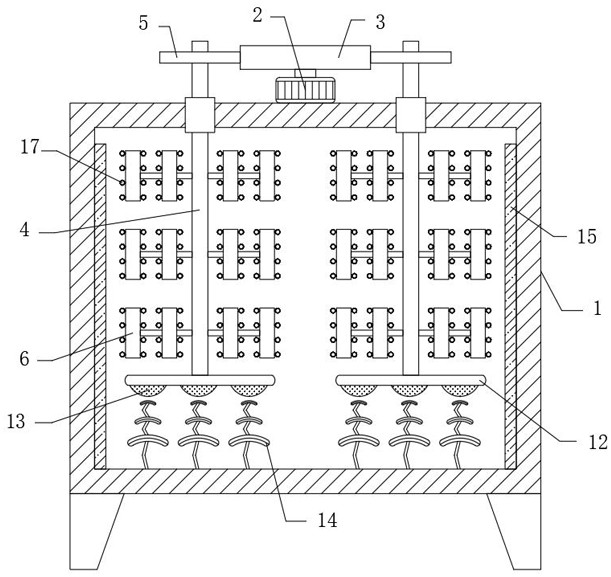

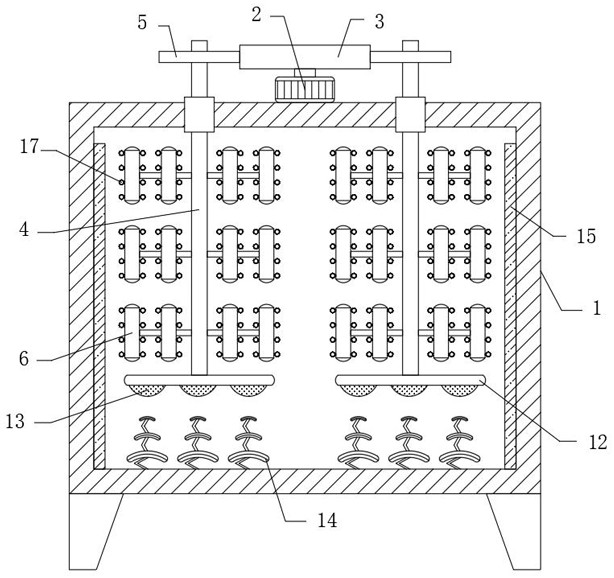

[0049] see Figure 1-7 , a preparation process of high lubricating oil agent for textile, please refer to figure 1 , including the blending tank body 1,

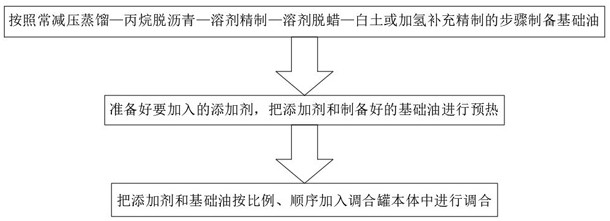

[0050] Include the following steps:

[0051] S1, prepare base oil according to the steps of atmospheric and vacuum distillation-propane deasphalting-solvent refining-solvent dewaxing-clay or hydrogenation supplementary refining;

[0052] S2, prepare the additives to be added, and preheat the additives and the prepared base oil;

[0053] S3, adding the additive and the base oil in proportion and order to the blending tank body 1 for blending;

[0054] The preheating temperature in step S2 is 50°C-68°C. If the temperature is too high, it may cause oxidation or thermal deterioration of the oil and additives. If the temperature is too low, the fluidity of the components will deteriorate and affect the effect, so the temperature should be moderate;

[0055] see Figure 2-3 with Figure 7 , the blending tank body 1 is compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com