Beryllium sheet packaging structure of X-ray tube

A packaging structure, X-ray tube technology, applied in the directions of X-ray tube parts, X-ray tube shell/container, etc., can solve the problem of poor wettability and fluidity, low X-ray transmittance, and X-ray quality degradation problem, to achieve the effect of easy disassembly, good heat transfer effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described now in conjunction with accompanying drawing.

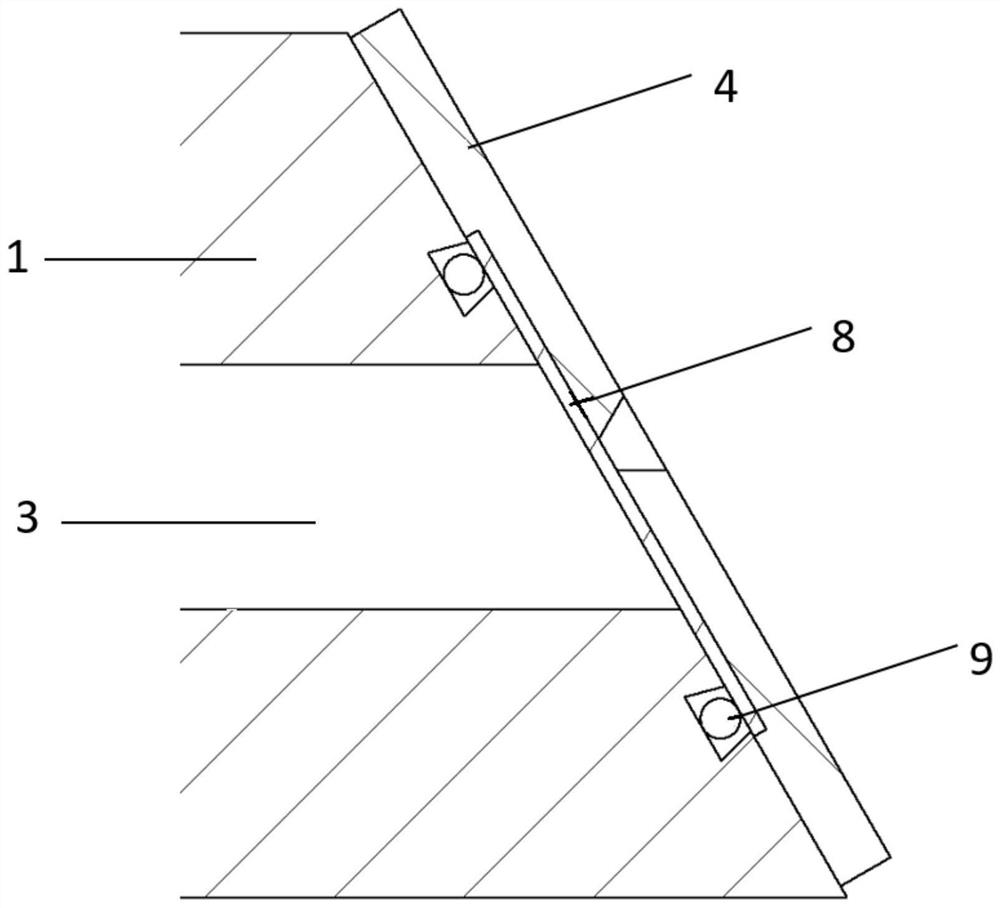

[0026] Such as figure 1 and 2 As shown, the present invention provides a beryllium sheet package structure of an X-ray tube, which package structure includes: an anode seat 1, a beryllium window mounting seat 4, a beryllium sheet 8 and a rubber sealing ring 9;

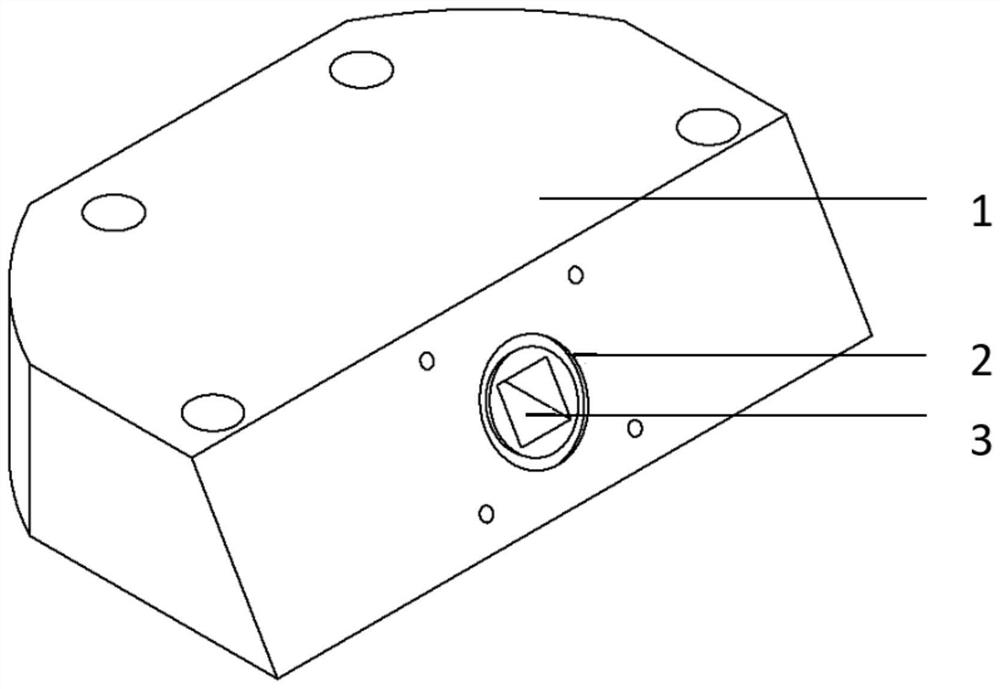

[0027] Wherein, the anode holder 1 is a polyhedron structure, and the middle part in the anode holder 1 is provided with an X-ray outlet hole 3 that runs through the anode holder 1, and one end of the X-ray outlet hole 3 is arranged on a cross section of the anode holder 1. The oblique side of the rectangle, wherein the inclination angle of the oblique side is generally between 30-60 degrees;

[0028] Such as image 3 As shown, a circular groove 2 and a plurality of installation holes 7 are provided on the slope side; the circular groove 2 is set outside the X-ray exit hole 3, and the X-ray exit hole is wrapped in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com