Rotary vertical take-off and landing spray pipe based on quasi-axisymmetric throat offset type pneumatic vectoring spray pipe and design method of rotary vertical take-off and landing spray pipe

A vector nozzle, vertical take-off and landing technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve the problems of difficult maintenance, difficult control, complex nozzle structure, etc., to achieve small size and less mechanical structure. , the effect of reducing the number of parts and adjusting the complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

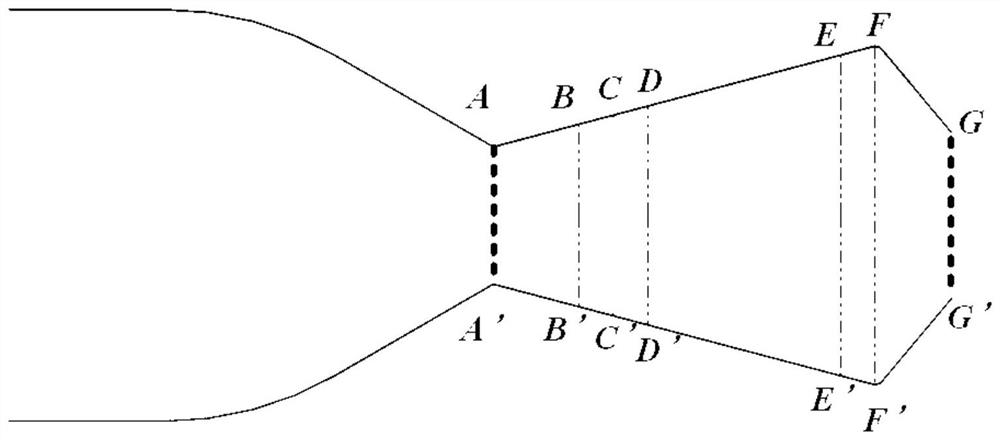

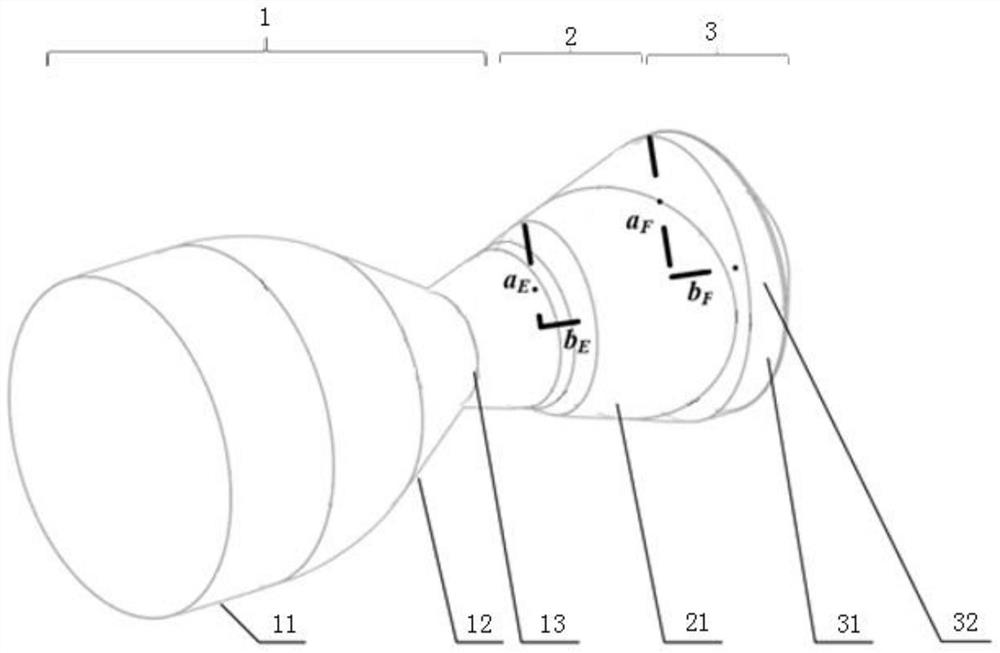

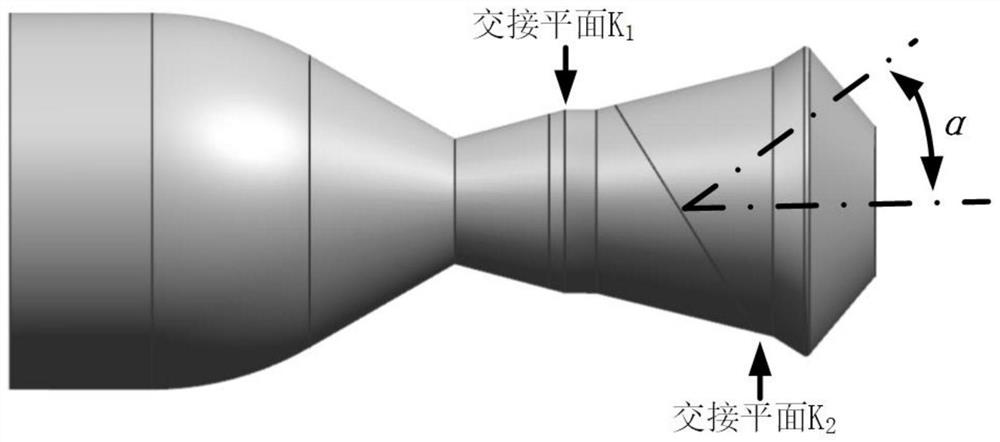

[0079] Rotating VTOL nozzle based on a throat-offset aerodynamic vectoring nozzle for a typical configuration.

[0080] Figure 8a , Figure 8b What the two figures show is the specific embodiment of the aerodynamic vectoring nozzle using the mechanically disturbed throat displacement type. The ratio of the minor axis to the major axis of the conical surface of this configuration m=b D / a D =b E / a E =0.85, α=arc cos0.85=58.21°. in, Figure 8a Shown is the internal flow field of a nozzle with no disturbance applied near the throat. It can be seen that the airflow of the present invention turns to about 50 degrees at this time, thus vertical take-off and landing cannot be realized. However, when the spoiler that controls the bowing direction is stretched out, the vector nozzle produces a larger angle of airflow deflection.

[0081] Therefore, the present invention further optimizes the value of m for a specific configuration by further optimizing the design, and in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com