Sleeve for fabricated wall surface

A prefabricated, sleeve technology, applied in covering/lining, construction, building structure, etc., can solve the problems of inability to be dedicated, disgusting, inconvenient, etc., and achieve the effect of simple structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

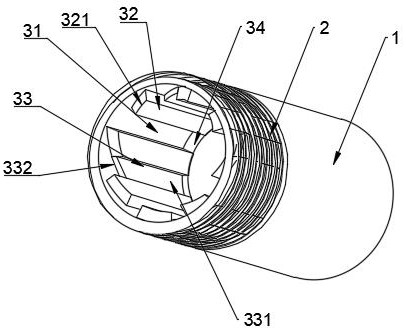

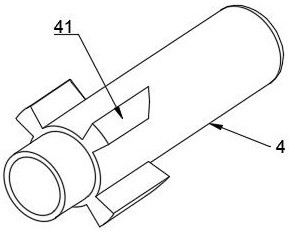

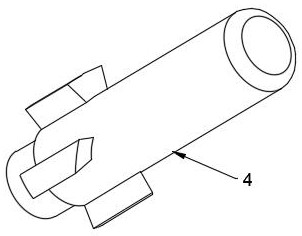

[0029] Such as Figure 1 to Figure 7 As shown, this embodiment provides an assembled wall sleeve, including an inner wall and an outer wall, one end of the outer wall is a thread 2, and the other end is a smooth curved surface 1; the inner wall at one end of the thread 2 is uniformly arranged with four connecting parts along the circumferential direction 3. Each connecting part 3 includes a first groove 31, a stopper 32 and a connecting block 33. A triangular groove 332 is formed between the end of the connecting block 33 and the end of the stopper 32, and the triangular groove 332 is clamped and fitted on the The first wedge-shaped column 41 of the movable tube 4; the end of the stopper 32 has a first inclined surface 321, and the first inclined surface 321 is slidably fitted with the first wedge-shaped column 41; the first groove 31 is slidably fitted with the second wedge-shaped Column 51.

[0030] Wherein, the connecting block 33 is provided with a second groove 331 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com