Automatic stacking machine for special-shaped bottles

A special-shaped bottle and palletizer technology, applied in conveyors, object stacking, object unstacking and other directions, can solve the problems of not being able to rely on each other, prone to mutual misalignment, unfavorable labeling, packing, etc. Achieve the effect of reducing packaging and transportation costs, placing compactly, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments;

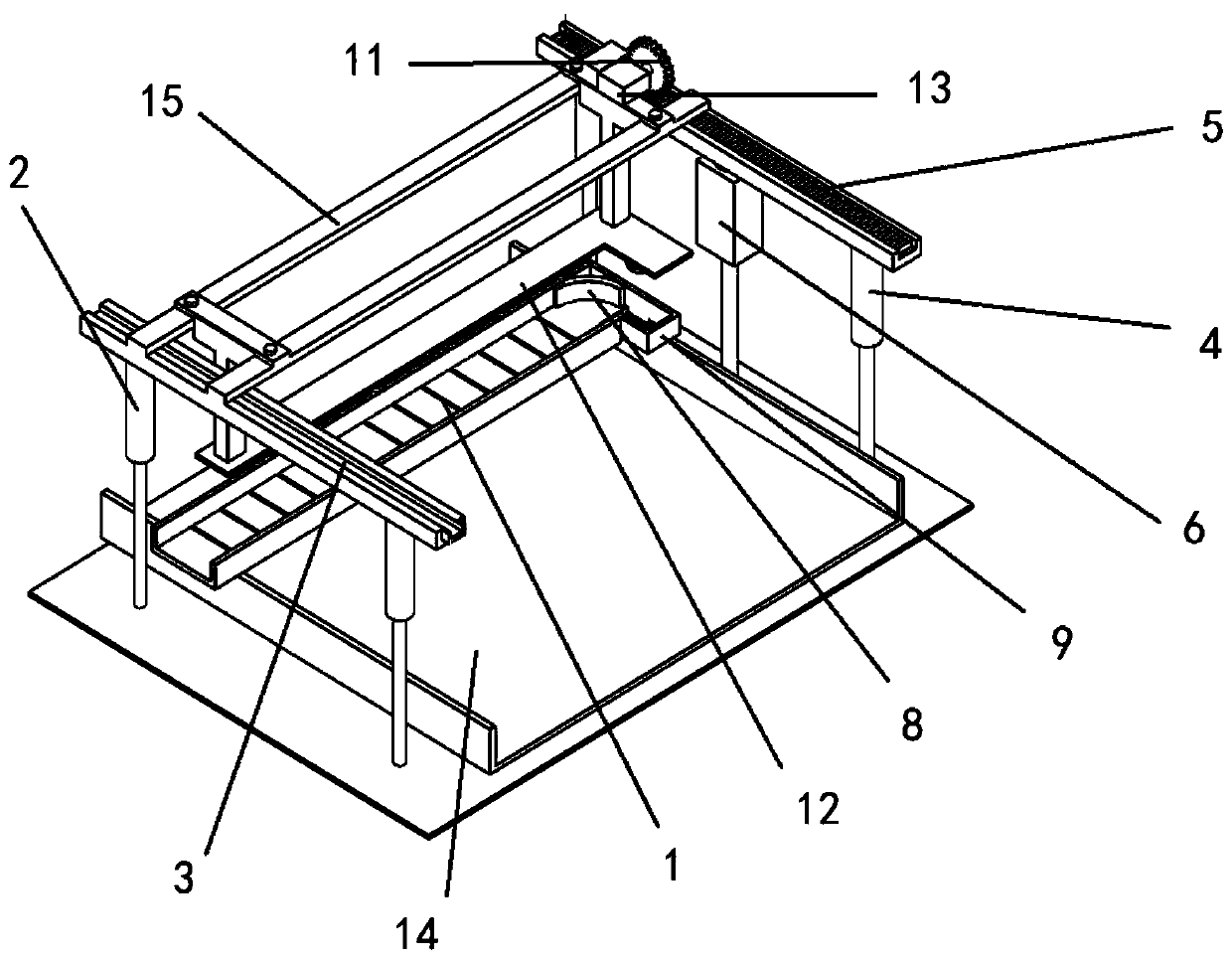

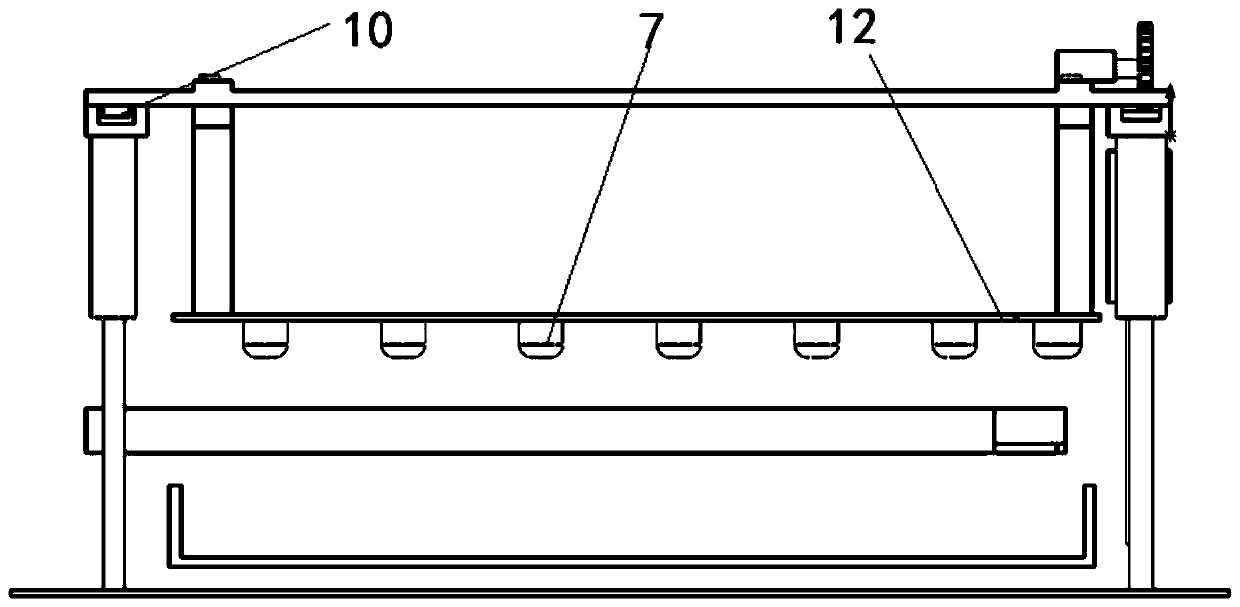

[0015] An automatic palletizer for special-shaped bottles, comprising a first lifting mechanism and a second lifting mechanism symmetrically arranged perpendicular to the conveyor belt 1; a clamping device for special-shaped bottles is erected between the first lifting mechanism and the second lifting mechanism;

[0016] The first lifting mechanism includes telescopic guide rods 2 arranged symmetrically, and slide rails 3 are erected on the telescopic guide rods 2;

[0017] The second lifting mechanism includes a symmetrically arranged second telescopic guide rod 4, and a rack 5 is erected between the two second telescopic guide rods 4, and a lifting cylinder 6 is arranged at the lower end of the rack 5;

[0018] The special-shaped bottle cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com