Pressing head for fabricated wall surface

A prefabricated, sloped technology, applied in the field of architectural decoration, can solve problems such as disgust, inconvenience, bumping into patients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

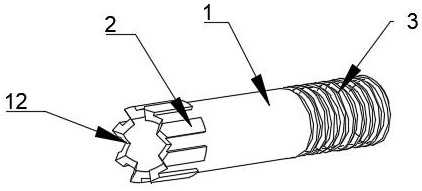

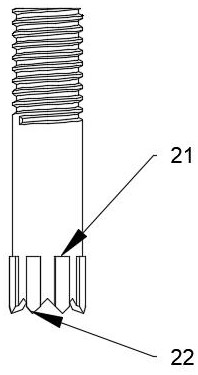

[0032] like Figure 1 to Figure 9 As shown, this embodiment provides an assembled wall pressing head, including a circular tube 1 and a wedge-shaped column 2, wherein the circular tube 1 is a hollow structure, and the wedge-shaped column 2 is fixed on the outer wall of the circular tube 1. The end of 1 has a tooth-shaped groove 12, and the wedge-shaped column 2 and the tooth-shaped groove 12 are integrally formed.

[0033] The pressing head of this embodiment cooperates with the movable tube 4 , the sleeve 5 and the fixing member 6 , the hollow structure and the toothed groove 12 cooperate with the movable tube 4 respectively, and the wedge-shaped column 2 cooperates with the sleeve 5 .

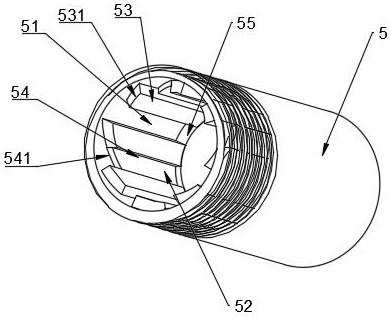

[0034] There are eight wedge-shaped columns 2 , and the eight wedge-shaped columns 2 are evenly distributed along the circumference of the outer wall of the circular tube 1 . The inner wall of the sleeve 5 has grooves, the grooves include a first groove 51 and a second groove 52, and two adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com