Rapid forming die for machining parts with holes

A technology for forming molds and parts, which is applied in the field of rapid prototyping molds, can solve the problems of reducing production efficiency of parts, reducing part quality, easy shaking of molds, etc., and achieves the effect of improving production efficiency, improving molding quality, and good demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

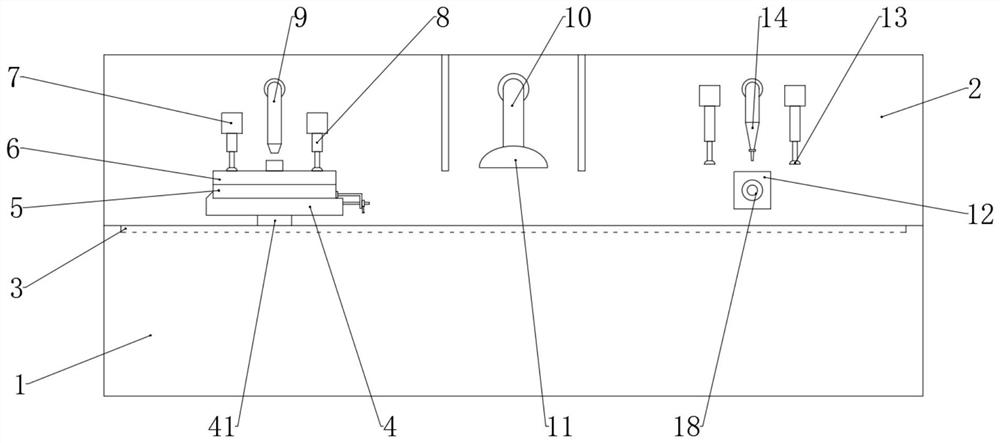

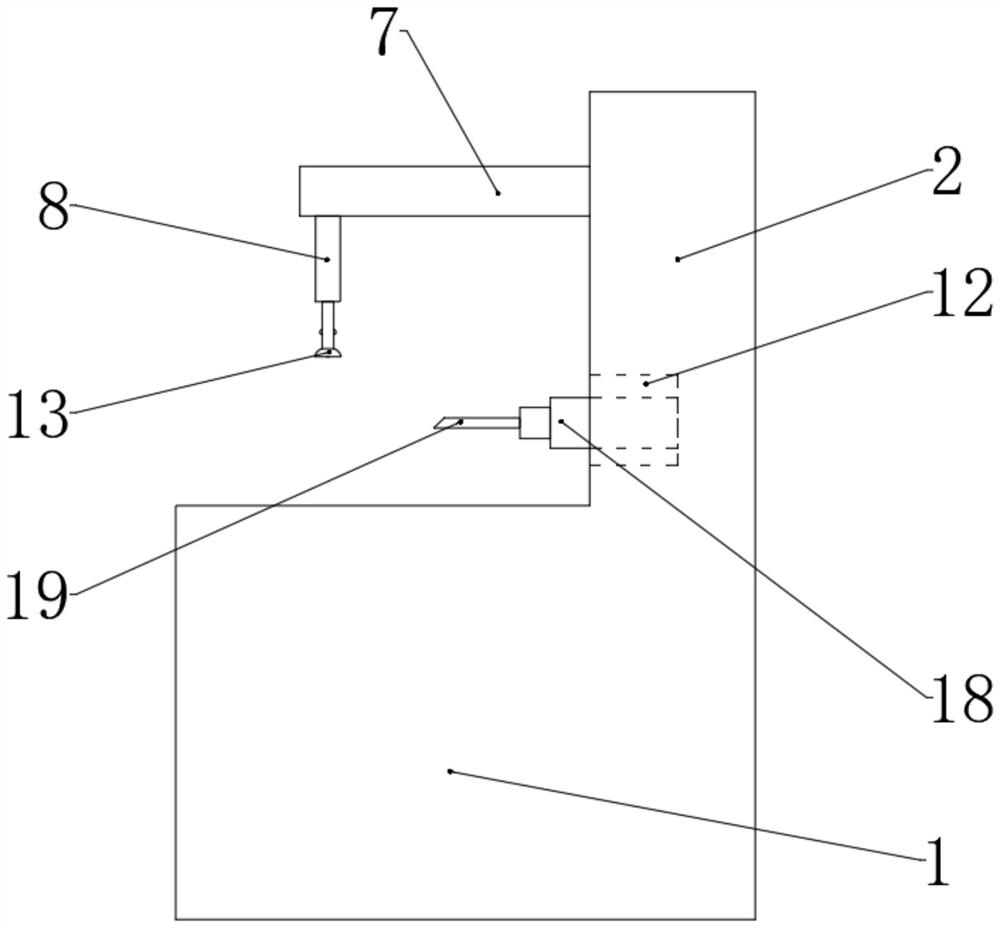

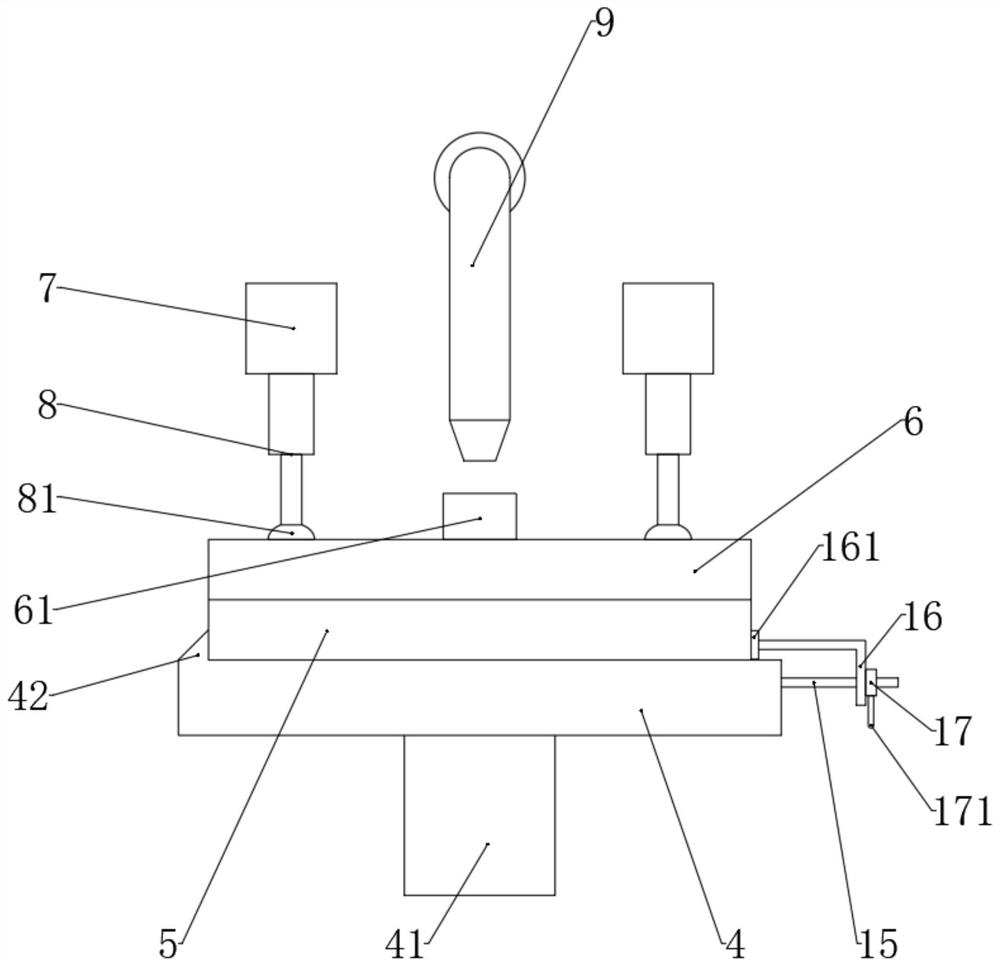

[0023] This embodiment 1 has introduced a kind of rapid prototyping mold for the processing of parts with holes, including base platform 1, vertical plate 2 and mold group, such as figure 1 and image 3 As shown, the vertical plate 2 is fixed on the top rear side of the base platform 1, the base plate 4 is slidably installed on the top front side of the base platform 1, and the slide rail 3 is provided on the top front side of the base platform 1 The middle of the bottom of the base plate 4 extends downwards and is fixed with an electric slider 41 that cooperates with the slide rail 3. The mold set includes a lower mold 5 and an upper mold 6, and a lower mold is arranged in the middle of the top of the lower mold 5. Cavity, the upper mold cavity is arranged in the middle of the bottom of the upper mold 6, the bottom of the material receiving pipe 61 communicates with the upper mold cavity, the lower mold 5 is placed on the top of the base plate 4, and the left side of the base...

Embodiment 2

[0025]This embodiment 2 introduces a rapid prototyping mold for processing parts with holes, including a base platform 1, a vertical plate 2 and a mold set, the vertical plate 2 is fixed on the rear side of the top of the base platform 1, A base plate 4 is slidably installed on the front side of the top of the base platform 1, and the mold set includes a lower mold 5 and an upper mold 6. The end of the base plate 4 near the vertical plate 2 is provided with a tunnel 43, and the lower mold set includes a lower mold 5 and an upper mold 6. A cylindrical rod 20 is movably installed at the bottom of the mold 5, and the bottom of the cylindrical rod 20 extends to the inside of the tunnel 43. A lower mold cavity is arranged in the middle of the top of the lower mold 5, and the bottom of the lower mold 5 is provided with a A through hole communicating with the cavity, the top of the base plate 4 is provided with a through hole one communicating with the channel 43, the through hole one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com