Processing equipment for high-performance self-cleaning epoxy resin coating

A technology of epoxy resin coating and processing equipment, which is applied in the direction of metal processing equipment, grinding/polishing equipment, manufacturing tools, etc. It can solve the problems of dust left on the ground, troublesome cleaning, and insufficient suction of vacuum fans, etc., to achieve The effect of reducing the gap, good dust suction effect, and speeding up the removal and fixing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

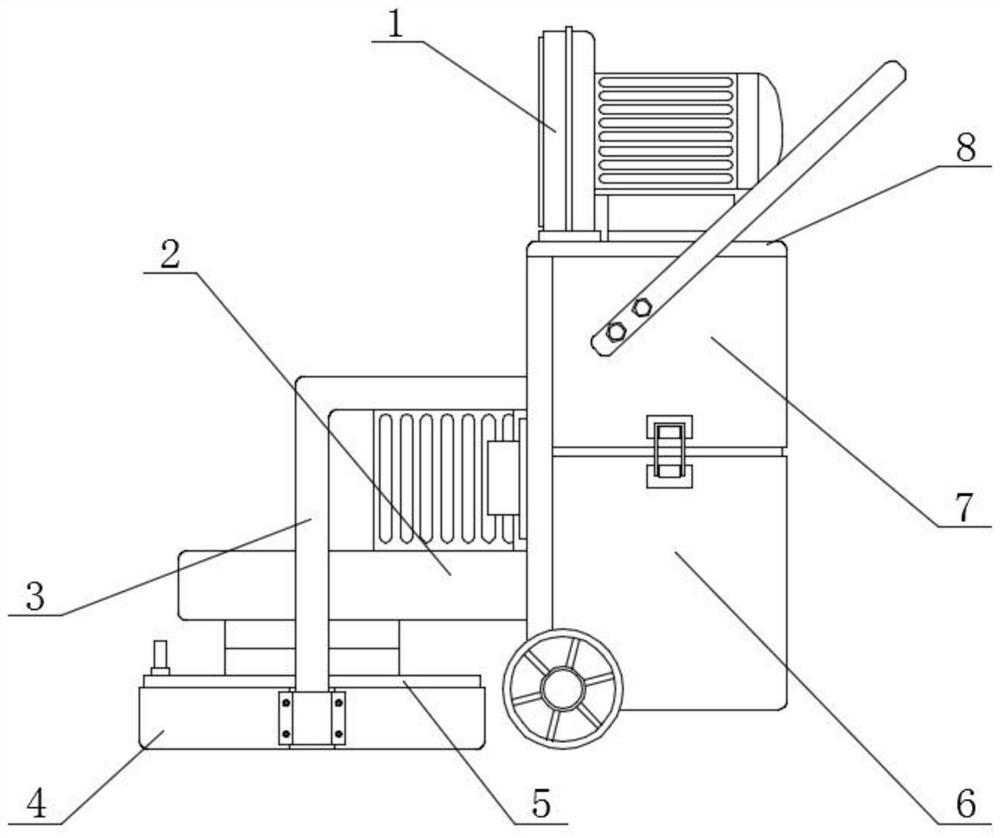

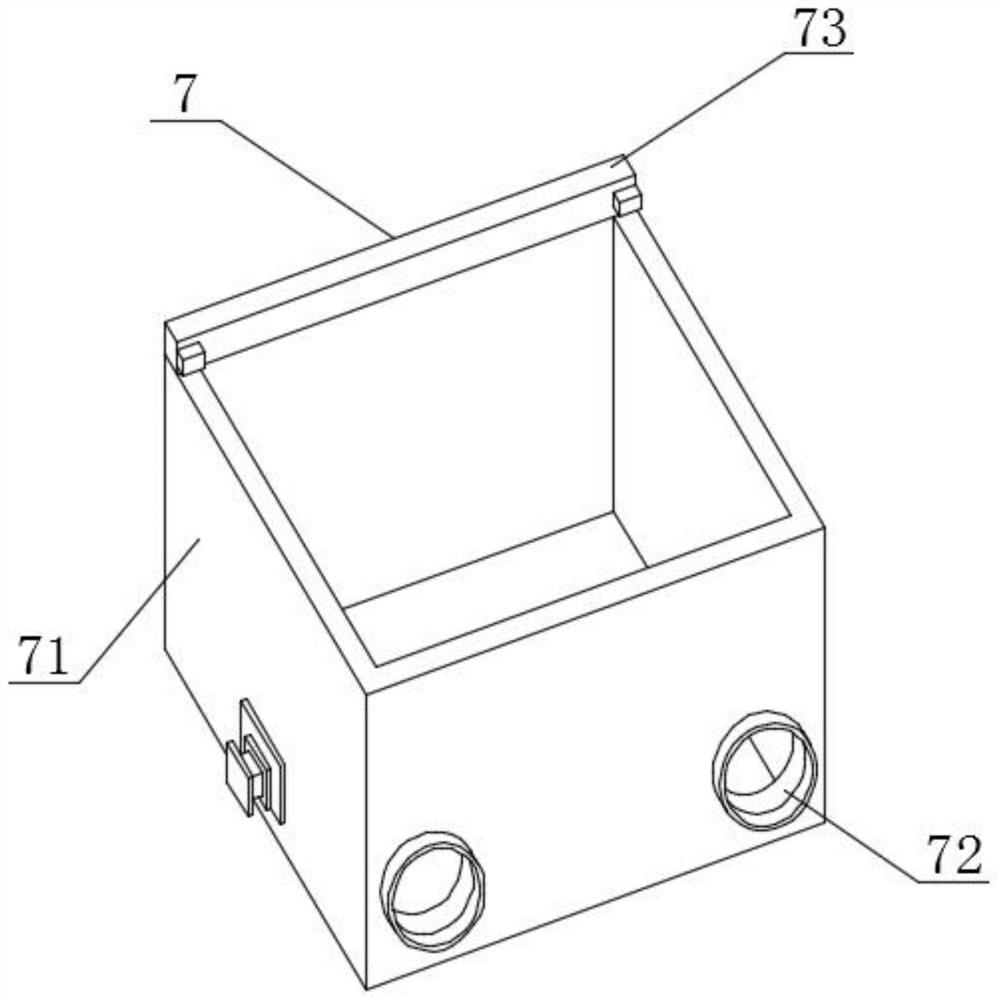

[0024] Such as Figure 1-2 As shown, a high-performance self-cleaning epoxy resin coating processing equipment includes a casing 6, the upper end of the casing 6 is clamped with a dust collection box 7, and the upper end of the dust collection box 7 is clamped with a rectangular plate 8. The upper end of the plate 8 is fixed with a dust suction fan 1 by bolts, the left end of the casing 6 is fixed with a belt cover 2, the lower end of the belt cover 2 is fixed with a circular plate 5, and the lower end of the circular plate 5 is fixed with a dust cover 4, the dust cover The front end of 4 is fixed with suction pipe 3, and dust collection box 7 comprises casing 71, and the front end of casing 71 is fixed with connecting pipe 72, and the upper end of casing 71 is fixed with rubber rod 73.

[0025] The connecting pipe 72 can be well connected with the connecting ring on the surface of the dust suction pipe 3. When there is too much dust inside the dust collection box 7 and needs ...

Embodiment 2

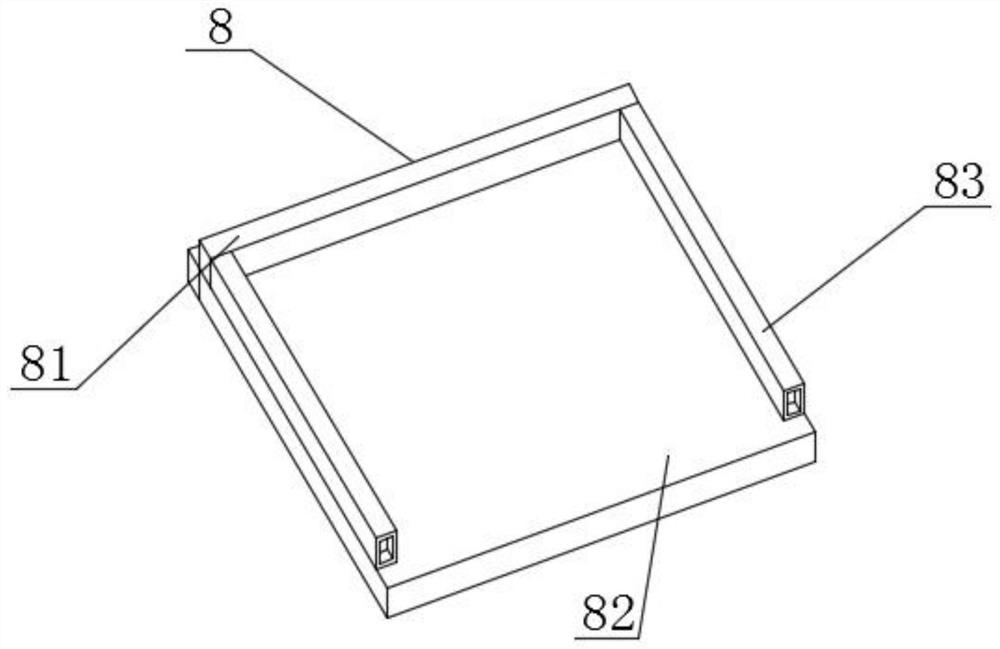

[0027] Such as Figure 1-3 As shown, a high-performance self-cleaning epoxy resin coating processing equipment includes a casing 6, the upper end of the casing 6 is clamped with a dust collection box 7, and the upper end of the dust collection box 7 is clamped with a rectangular plate 8. The upper end of the plate 8 is fixed with a dust suction fan 1 by bolts, the left end of the casing 6 is fixed with a belt cover 2, the lower end of the belt cover 2 is fixed with a circular plate 5, and the lower end of the circular plate 5 is fixed with a dust cover 4, the dust cover The front end of 4 is fixed with dust suction pipe 3, and rectangular plate 8 comprises plate body 82, and the upper end of plate body 82 is fixed with rubber block 81, and the front end of rubber block 81 is fixed with sealing rod 83.

[0028] The plate body 82 is connected to the surface of the casing 6 to stabilize the position of the plate body 82. The stable plate body 82 is attached to the surface of the ...

Embodiment 3

[0030] Such as Figure 1-4 As shown, a high-performance self-cleaning epoxy resin coating processing equipment includes a casing 6, the upper end of the casing 6 is clamped with a dust collection box 7, and the upper end of the dust collection box 7 is clamped with a rectangular plate 8. The upper end of the plate 8 is fixed with a dust suction fan 1 by bolts, the left end of the casing 6 is fixed with a belt cover 2, the lower end of the belt cover 2 is fixed with a circular plate 5, and the lower end of the circular plate 5 is fixed with a dust cover 4, the dust cover The front end of 4 is fixed with dust suction pipe 3, and dustproof cover 4 comprises cover body 41, and the inner surface of cover body 41 is fixed with retaining ring 42.

[0031] The cover body 41 can be well connected with the dust suction pipe 3, the dust suction pipe 3 sucks away the dust inside the cover body 41, the retaining ring 42 is in contact with the ground, and the retaining ring 42 in contact wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com