Steel bar binding device for construction site

A technology for tying steel bars and construction sites, which is applied in the processing of building materials, construction, building construction, etc., and can solve the problems of low work efficiency, large workload, and cumbersome operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

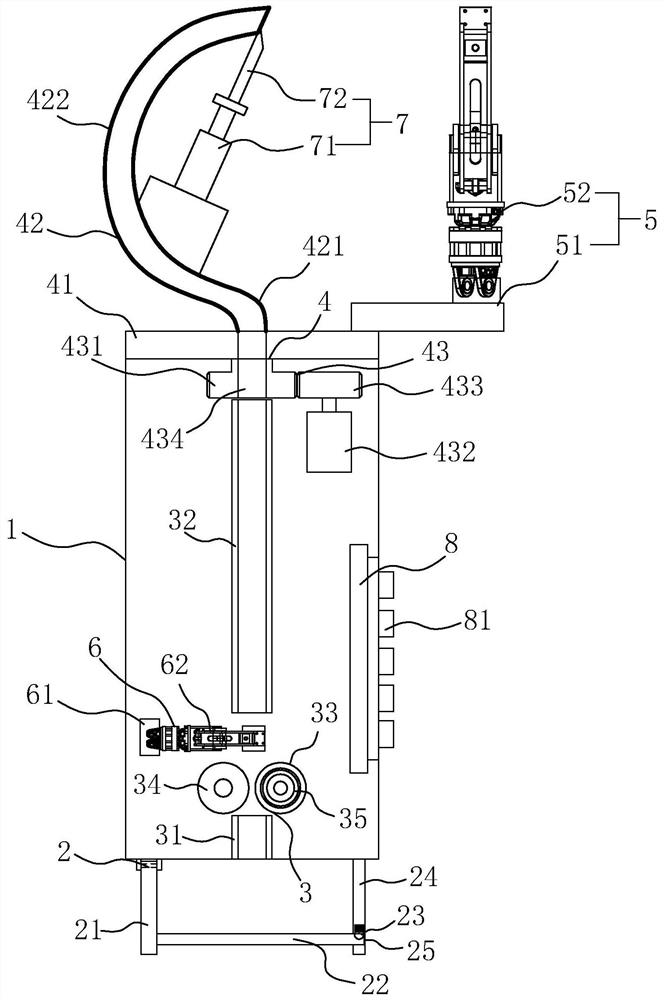

[0037] A steel bar binding device for construction sites, such as figure 1As shown, it includes: installation case 1, the rear end of the installation case 1 is provided with an upper wire mechanism 2 for installing the wire reel; a wire feeding mechanism 3 is arranged in the installation case 1 for driving the wire feeding forward Carried on the front end of the installation casing 1 for guiding the binding wire through the guide mechanism 4 to be bound, the guide mechanism 4 includes: a mounting seat 41 that is rotatably assembled on the installation casing 1, fixed on the mounting seat 41 and connected with the installation The arc-shaped guide tube 42 connected to the casing 1 and the rotation drive assembly 43 used to drive the rotation of the mounting base 41; the clamping mechanism 5 fixed on the mounting base 41 and arranged opposite to the arc-shaped guide tube 42, Between the curved guide pipe 42 is formed a port for the passage of steel bars to be bound; the locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com