Reactivated and stabilized layered ferric hydroxide as well as preparation method and application thereof

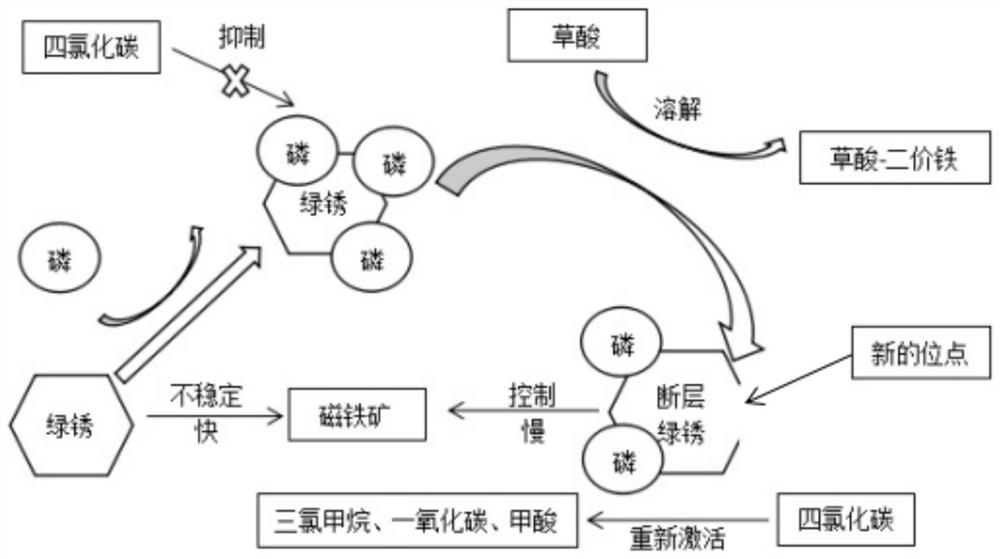

A ferric hydroxide and reactivation technology, applied in the field of environmental remediation, can solve problems such as difficult identification, achieve the effect of optimizing mass transfer, improving the efficiency of technology use, and degrading pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

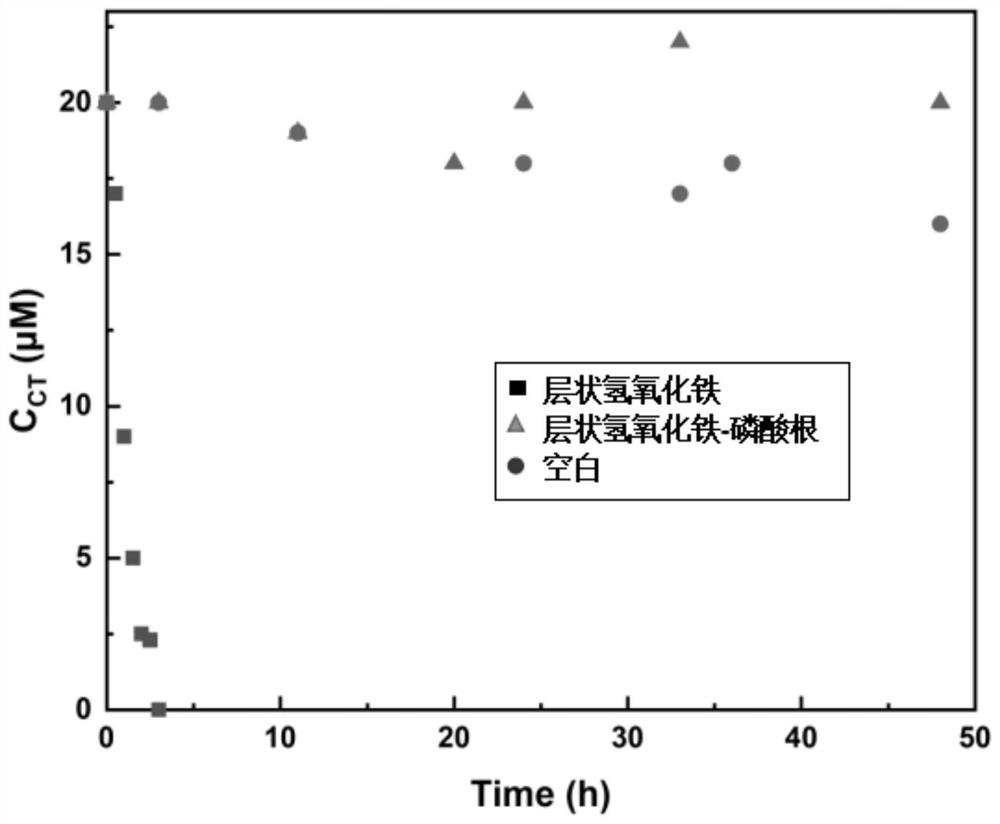

[0048] (1) sodium phosphate (Na 3 PO 4 12H 2O) be dissolved in anaerobic deionized water, adjust pH to be 8.0 by 1mol / L HCl solution, obtain the phosphate solution of 4mM, preserve under anaerobic condition for subsequent use;

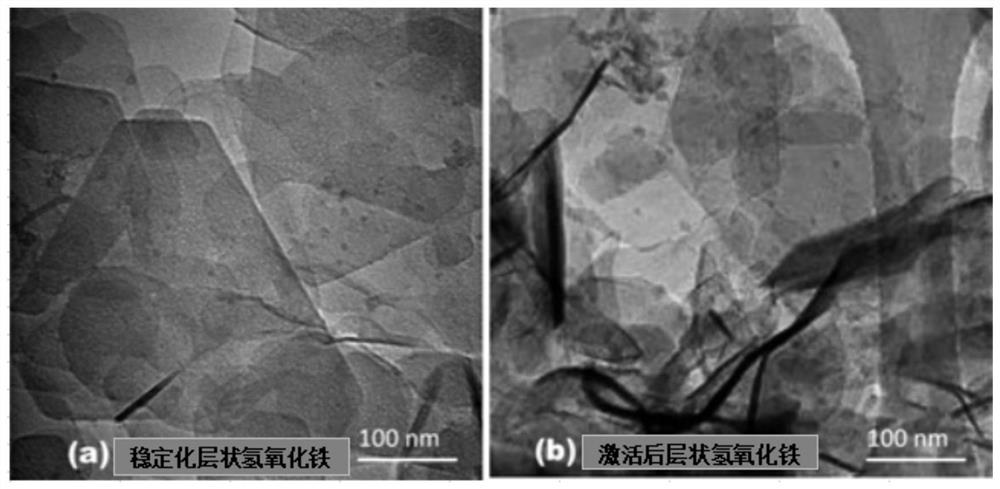

[0049] (2) Under anaerobic conditions, centrifuge 5 mL of layered ferric hydroxide suspension with a concentration of 60 mM (wherein the concentration of ferrous iron salt is 30 mM), remove the supernatant and retain the precipitate, and then add 10 mL of the solution from step (1) The prepared phosphate solution was magnetically stirred at room temperature at 25° C. for 12 h, so that the phosphate radical was fully adsorbed on the surface of layered ferric hydroxide, while maintaining the pH of the system at 8.0 to obtain a phosphate-layered ferric hydroxide suspension (stabilized layer like ferric hydroxide suspension);

[0050] (3) Weigh 3.6g of sodium oxalate and dissolve it in 450mL of anaerobic deionized water to obtain a 60mmol / L sodium oxala...

Embodiment 2

[0053] Other conditions are the same as in Example 1, wherein the concentration of sodium oxalate in step (4) is 30mM.

Embodiment 3

[0055] Other conditions are the same as in Example 1, wherein the concentration of sodium oxalate in step (4) is 120mM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com