Swing sliding type flapping rotor device

A flapping-rotor and sliding-type technology, applied in the field of aircraft, can solve the problems of strong air disturbance force and low ascent efficiency of flapping-rotor aircraft, and achieve the effects of strengthening the interference intensity, improving the disturbance intensity and improving the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

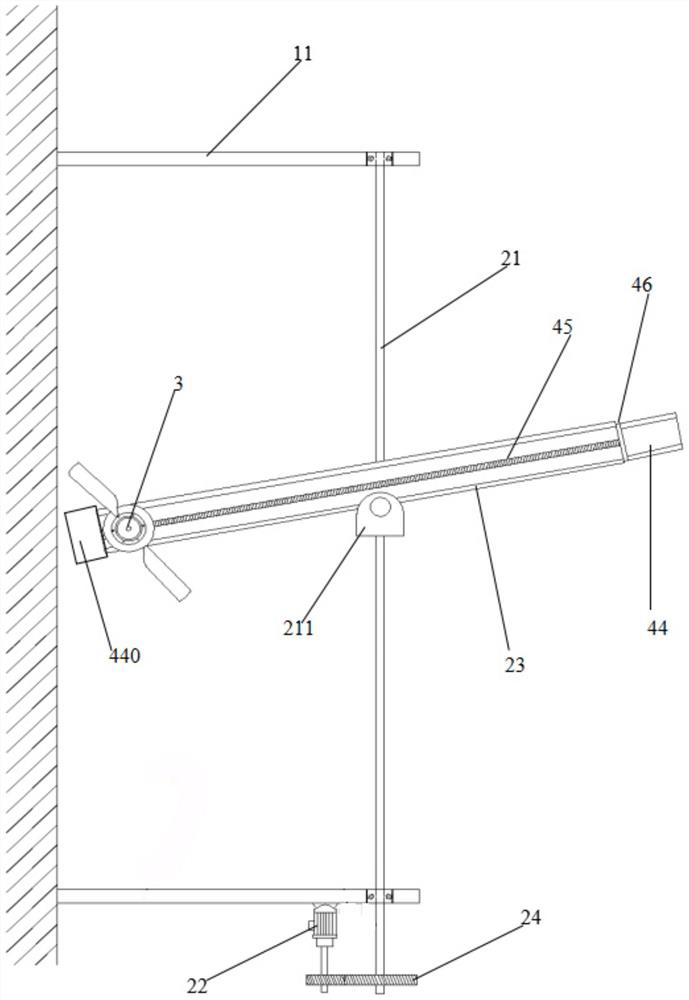

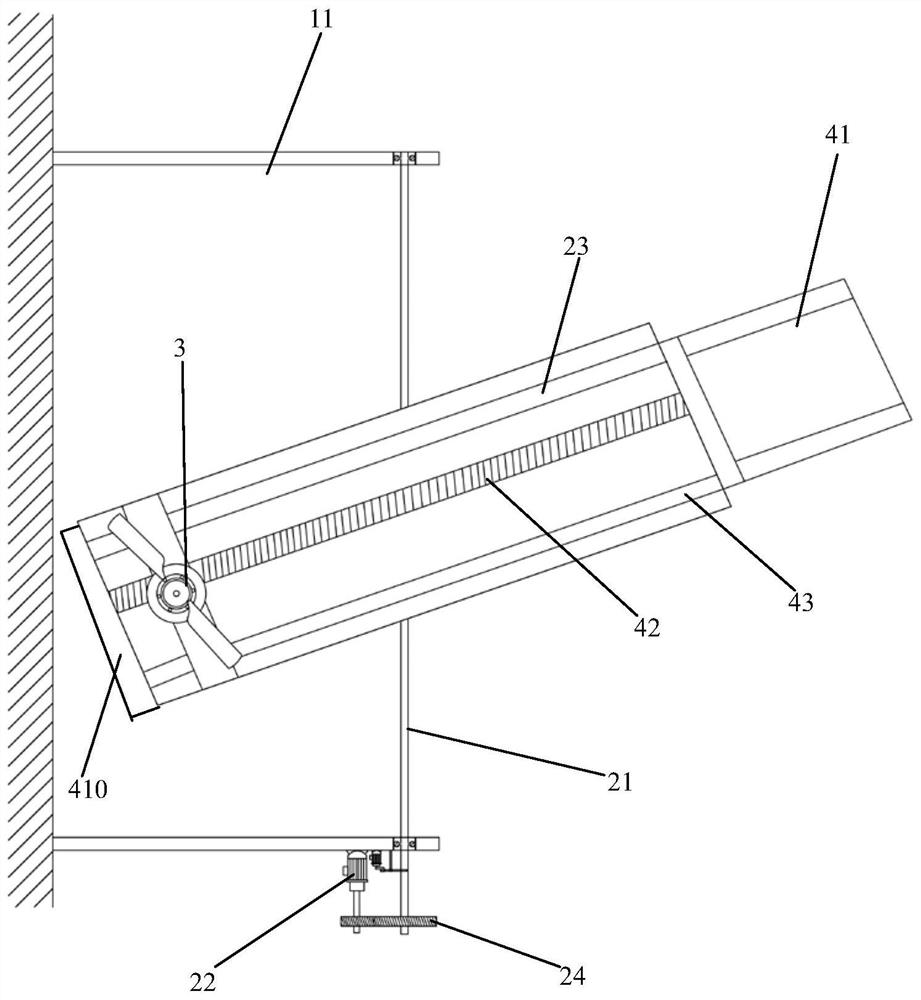

[0074] The embodiment of the present invention discloses a swinging and sliding flapping rotor device, which is symmetrically arranged on both sides of the fuselage, including: a front bracket 11, a rear bracket 12, a main shaft 21, a main shaft motor 22, a transmission gear set 24, a swing arm 23, Rotor 3, linear drive and controller;

[0075] The front support 11 and the rear support 12 are all vertically fixed on the side of the fuselage, and are parallel to each other and arranged at intervals:

[0076] The main shaft 21 is arranged between the front bracket 11 and the rear bracket 12, its axial centerline is parallel to the axial centerline of the fuselage, and its two ends are connected to the front bracket 11 and the rear bracket 12 through bearing rotation;

[0077] The main shaft motor 22 is fixed on the front bracket 11 or the rear bracket 12, and is connected to the main shaft 21 through the transmission gear set 24, and is electrically connected to the controller, ...

Embodiment 2

[0091] On the basis of Embodiment 1, there are multiple swing frames and first mounting bases 210, and the swing frames are connected to the first mounting bases 210 in one-to-one rotation through rotating shafts, and there is a phase difference among the multiple swing frames.

[0092] The present invention has a plurality of swinging frames, so that the interference intensity to the air can be strengthened, and the efficiency of the lift generation of the present invention can be further improved.

Embodiment 3

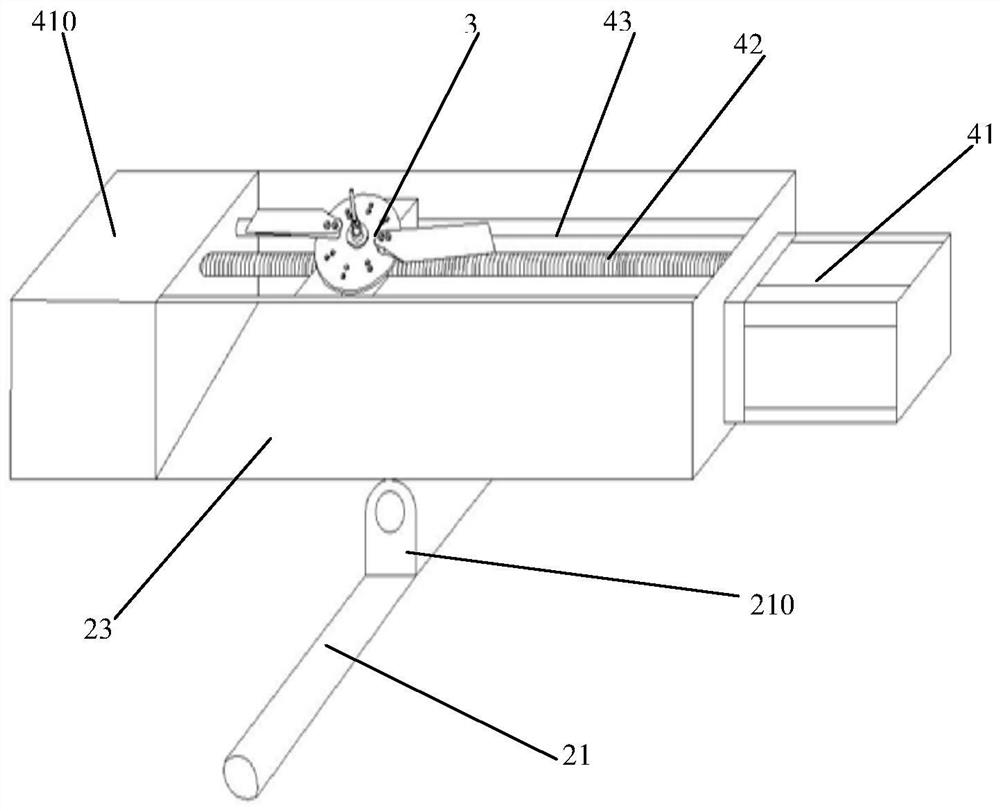

[0094] The difference from Embodiment 1 is that the swing arm 23 is a swing rod, the main shaft 21 is fixed with a second mount 211, and the center of the bottom of the swing frame is connected to the second mount 211 through a rotating shaft;

[0095] There are multiple swing rods and the second mounting base 211 , and the swing rods are connected to the second mounting bases 211 in one-to-one rotation through the rotating shaft, and there is a phase difference among the multiple swing rods.

[0096] The linear drive device includes a second motor 44, a second screw 45 and two vertical plates 46;

[0097] The second motor 44 is fixed on one end of the fork, and is electrically connected with the controller;

[0098] Two vertical plates 46 are parallel to each other, and are respectively fixed on the two ends of the fork;

[0099] The second lead screw 45 is arranged between the two vertical plates 46, and the two ends of the screw rod are rotatably connected with the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com