High-viscosity folder gluer

A folder-gluer, high-viscosity technology, used in the field of corrugated paper, can solve the problems of uneven paste adhesion affecting adhesion, wasting labor costs and paste reserves, reducing product qualification rate and quality, etc., to avoid paper viscosity. Insufficient, avoid rework production, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

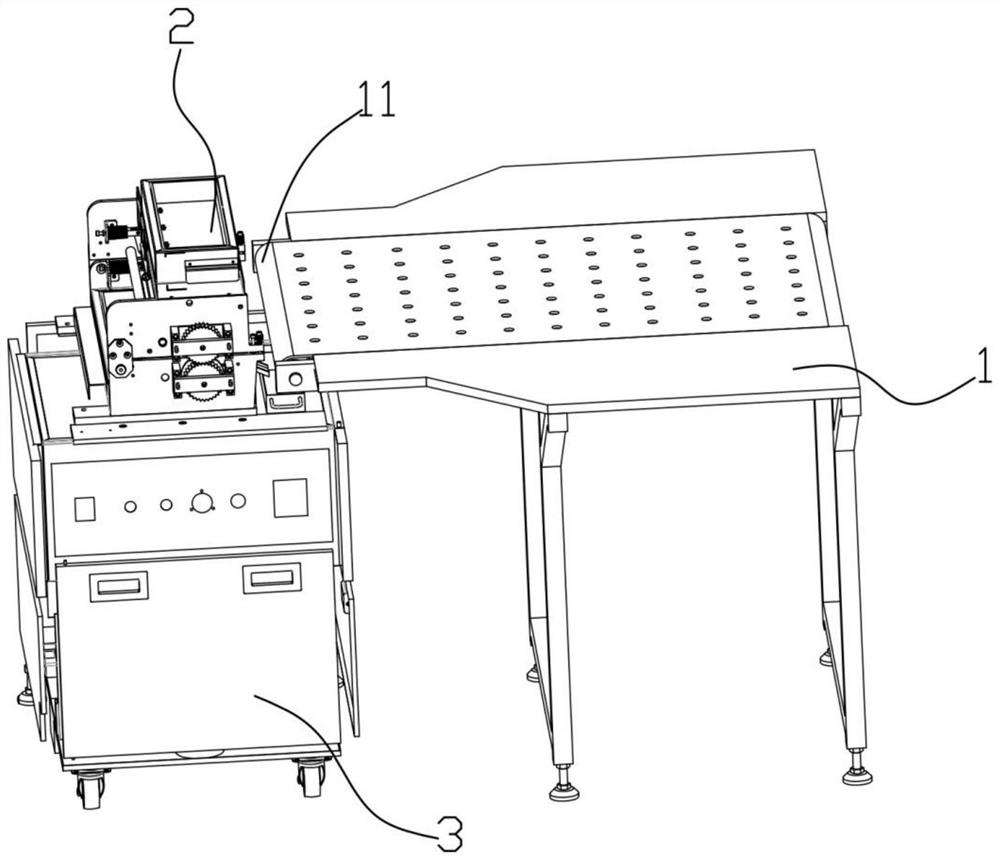

[0023] Such as figure 1 Shown: a high-viscosity folder-gluer, including a frame 1, a gluing device 2 and a motor cabinet 3, and a conveyor belt 11 is provided on the frame 1.

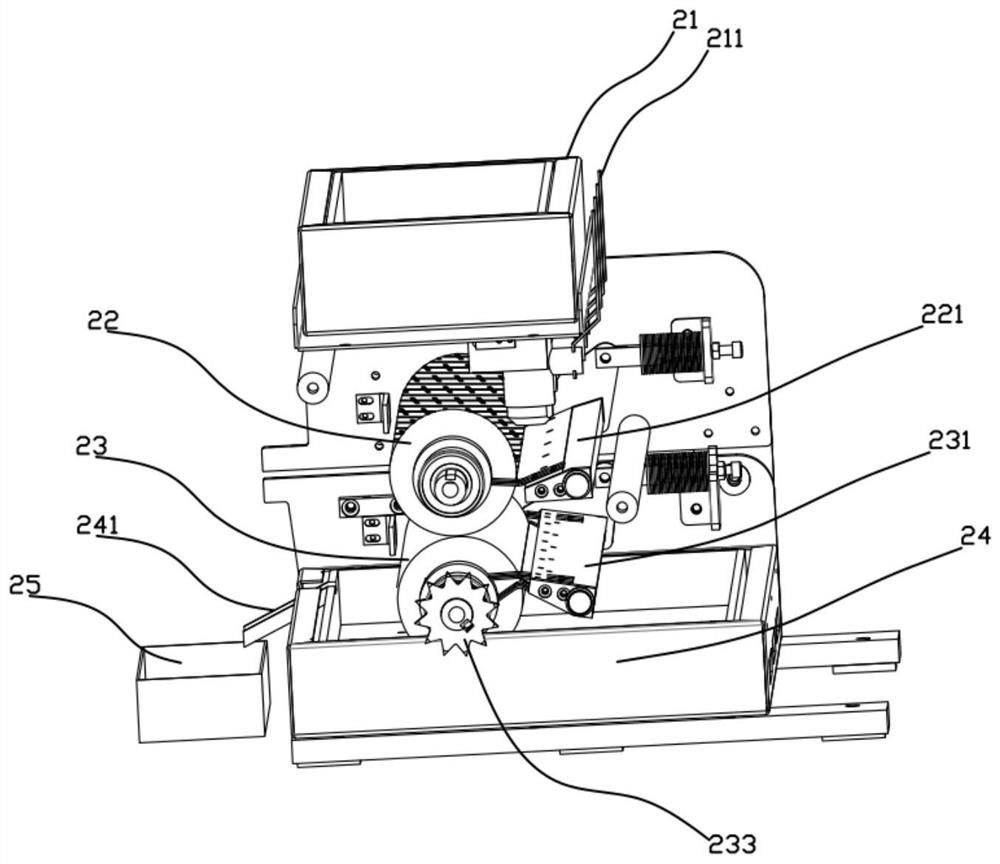

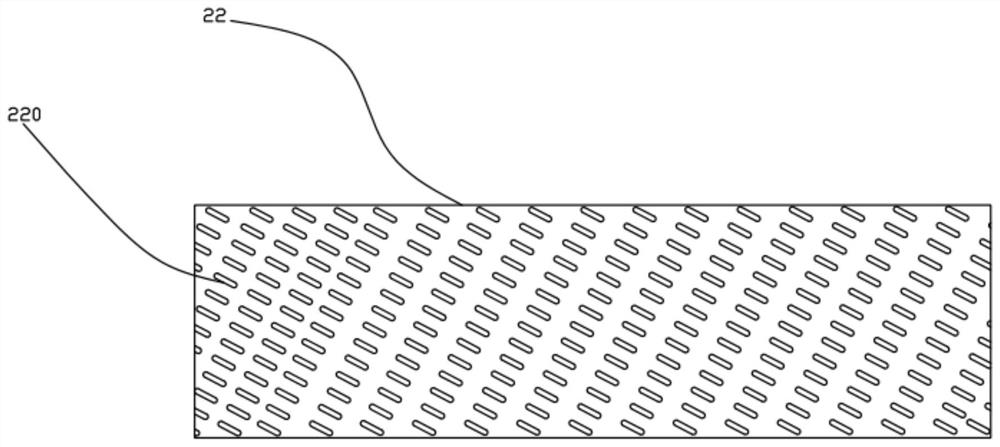

[0024] Such as figure 2 As shown: the pasting device 2 includes a paste top groove 21, a pasting valve 211, a pasting roller 22 and a pasting roller 23 arranged sequentially from top to bottom. The plate 221 leans downwards against the surface of the upper paste roller 22, the surface of the upper paste roller 22 is provided with a large number of embossed lines 220, the motor cabinet 3 is provided with a motor 31 for driving the rotation of the paste return roller, the upper paste roller 22 and the paste return Gear transmission between the rollers 23. The carton is transported to the pasting device 2 by the conveyor belt 11 on the frame 1, and the paste falls from the paste top groove 21 above to the upper pasting plate 221, and then is evenly applied to the pasting roller 22 by the pasting plate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com