Device for grinding and cleaning building plates

A technology for building boards and boards, which is applied to machine tools suitable for grinding workpiece edges, grinding drive devices, grinding/polishing safety devices, etc., which can solve the problem of reducing work efficiency, increasing working time and production costs, and grinding debris Into air and other issues, to reduce work efficiency, increase work time and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

[0023] The purpose of the present invention is to provide a device for grinding and cleaning building boards, so as to solve the problem that during the actual processing of building boards 10, due to the lack of dust removal structure in the grinding device, a large amount of grinding debris enters the air during the grinding process, which affects the staff. At the same time, due to the way of single-sided grinding, the work efficiency is reduced, the working time and production cost are increased. The dust in the grinding process is sprayed and precipitated by the present invention to prevent the dust generated by grinding from polluting the environment. At the same time, more Two grinding structures work at the same time, which improves the work efficiency.

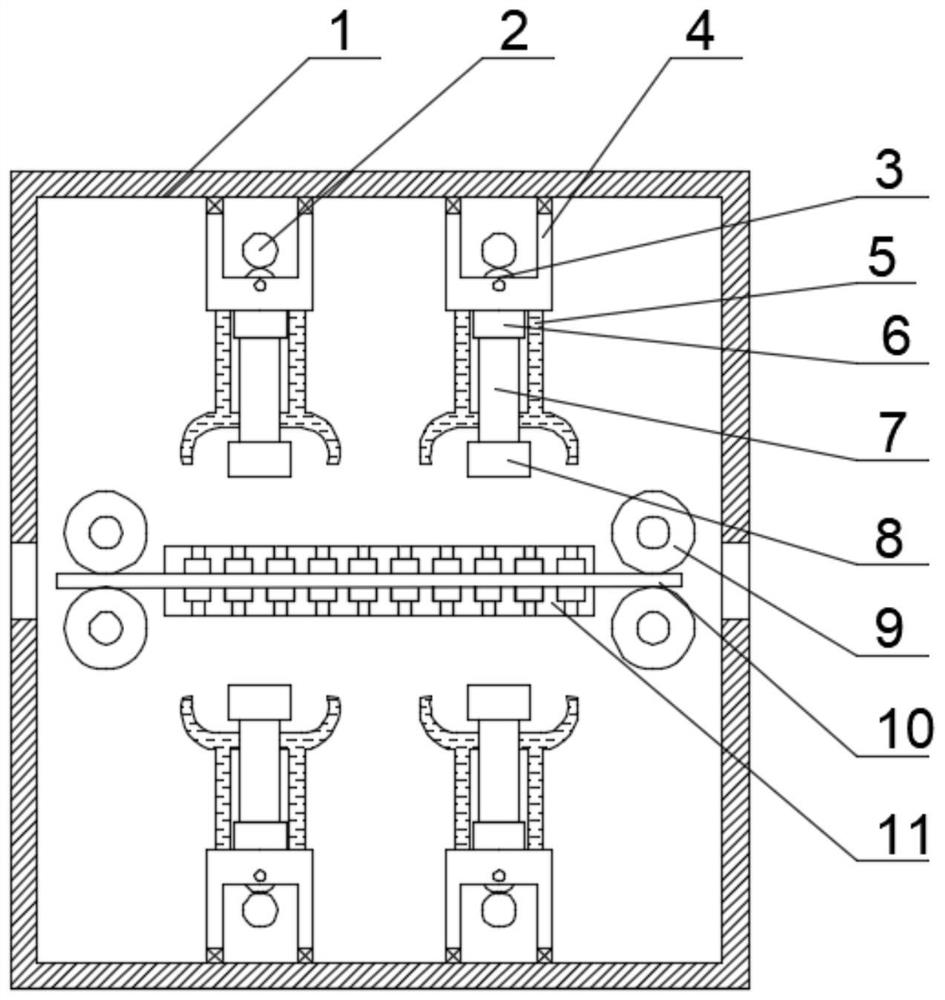

[0024] Such as figure 1 As shown, in the embodiment of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com