Perforating mechanism for industrial aluminum profile machining

A technology of aluminum profile processing and perforating mechanism, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing the cleanliness of the working environment, inconvenient collection of cutting fluid, scattered splashes, etc., to improve the cleaning effect and Work efficiency, convenient cleaning work, and the effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

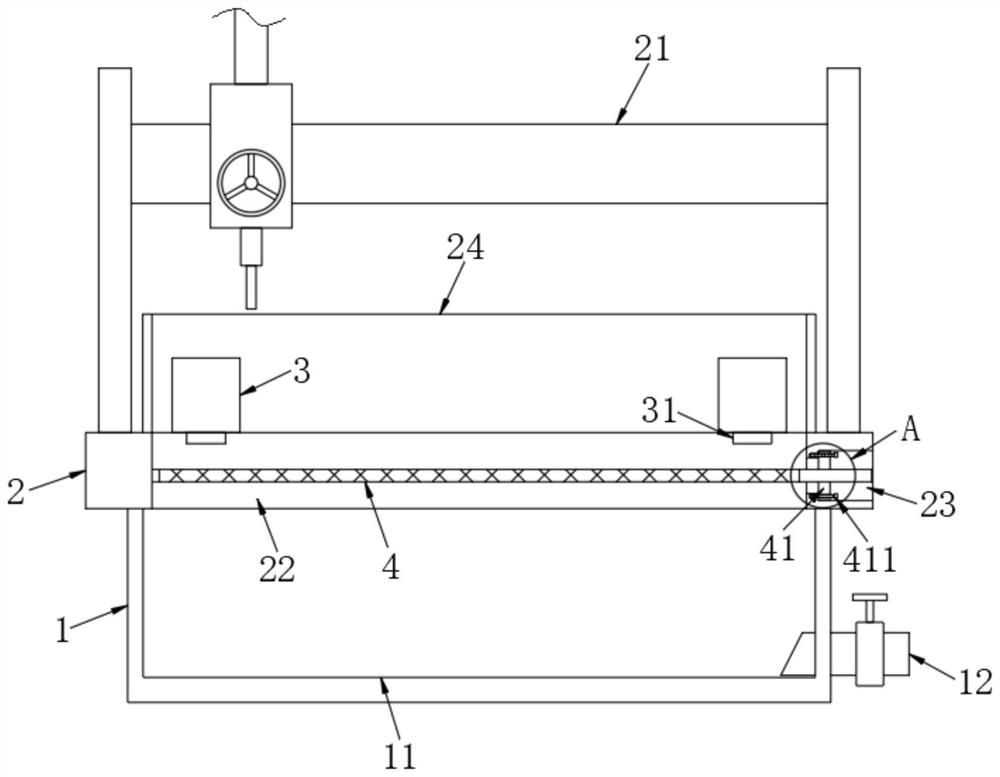

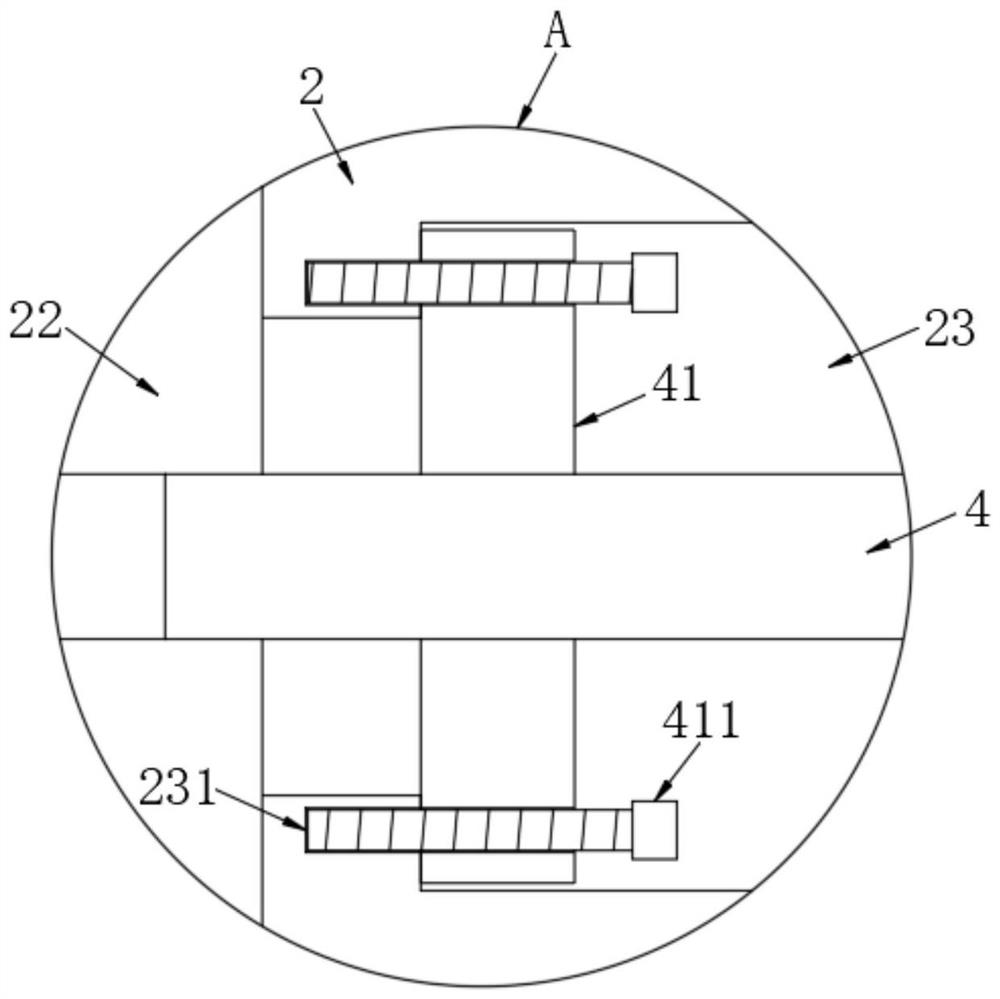

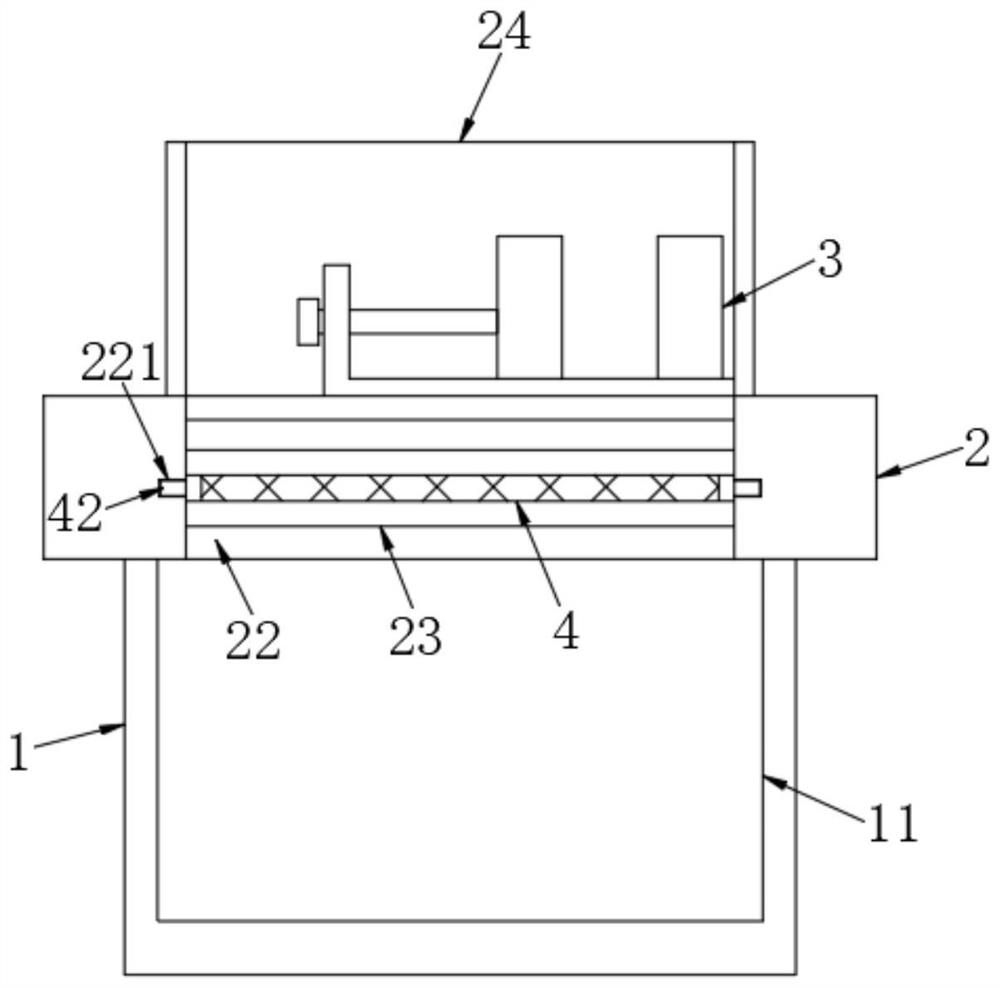

[0034] see Figure 1~4 , this specific embodiment describes in detail a piercing mechanism for industrial aluminum profile processing. The perforating mechanism includes a base 1 and a top plate 2 fixedly installed on the top of the base 1, and the base 1 and the top plate 2 are combined to form a workbench. The upper surface of the top plate 2 is positioned with a perforating assembly 21. This perforating assembly is a conventional perforating assembly in the art, generally including a gantry, which can be positioned and slid along the beam of the gantry and a perforating drill bit that can be positioned and moved up and down in the vertical direction. , its specific structure will not be repeated in this application and specific embodiments.

[0035] In the present application, the upper surface of the top plate 2 of the perforation mechanism is fixedly connected with a stop frame 24 arranged along the length direction of the top plate. The stop frame can be set as a stop p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com