Cosmetic processing stirring equipment

A technology for mixing equipment and cosmetics, applied in chemical instruments and methods, chemical/physical processes, mixers, etc., can solve the problems of affecting mixing effect, single action direction, reducing the relative speed of liquid material and mixing components, etc., to improve mixing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

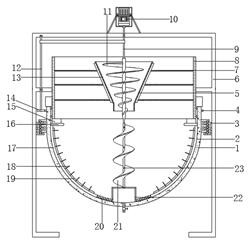

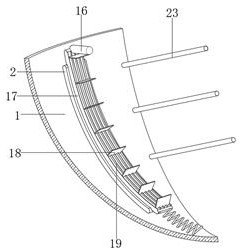

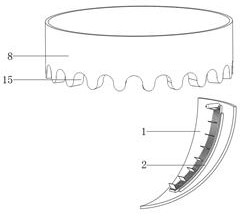

[0028] refer to Figure 1-4 , a cosmetics processing and stirring equipment, including a bottom tank 1 and a top tank 8, the bottom tank 1 and the top tank 8 are rotatably connected by a sealed bearing, the outer wall of the top tank 8 is welded with an outer frame 6, and the outer frame 6 and the bottom tank 1 The opposite sides are respectively welded with support ring plates 3, the cross sections of the support ring plates 3 are all E-shaped, and the opposite sides of the two support ring plates 3 are provided with annular grooves, corresponding to the rolling connection of the inner walls of the two annular grooves. Equidistantly distributed balls, the inner wall of the bottom tank 1 is welded with equidistant circularly distributed clamping rails 2, and the inner walls of the clamping rails 2 are slidably connected with sliding plates 17, and the top ends of the sliding plates 17 are welded with abutment columns 16, and The outer wall of the sliding plate 17 is respective...

Embodiment 2

[0037] refer to Figure 4-5, a kind of cosmetics processing and stirring equipment. Compared with Embodiment 1, this embodiment also includes that the circumferential outer wall of the liquid separation cylinder 5 is welded with liquid separation strips 24 distributed equidistantly, and the distance between the liquid separation strips 24 is from the top Decrease from bottom to bottom; using the liquid separation strips 24 whose distance decreases from top to bottom, the liquid material can be divided and mixed through the liquid separation strips 24 during the up-and-down convection process of the liquid material.

[0038] In the present invention, the conical spiral blade 11 is welded with liquid convection arc tubes 25 distributed in an equidistant ring, and the top ports of the liquid convection arc tubes 25 face outward.

[0039] When the present invention is in use: using the liquid separation strips 24 whose distances decrease sequentially from top to bottom, the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com