Electromagnetic levitation train track system

A magnetic levitation train and electromagnetic levitation technology, which is applied in the field of rail transit, can solve the problems of high leakage magnetic field, large energy consumption of levitation, and low service life, and achieve the effects of reducing the withstand voltage level, reducing costs, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

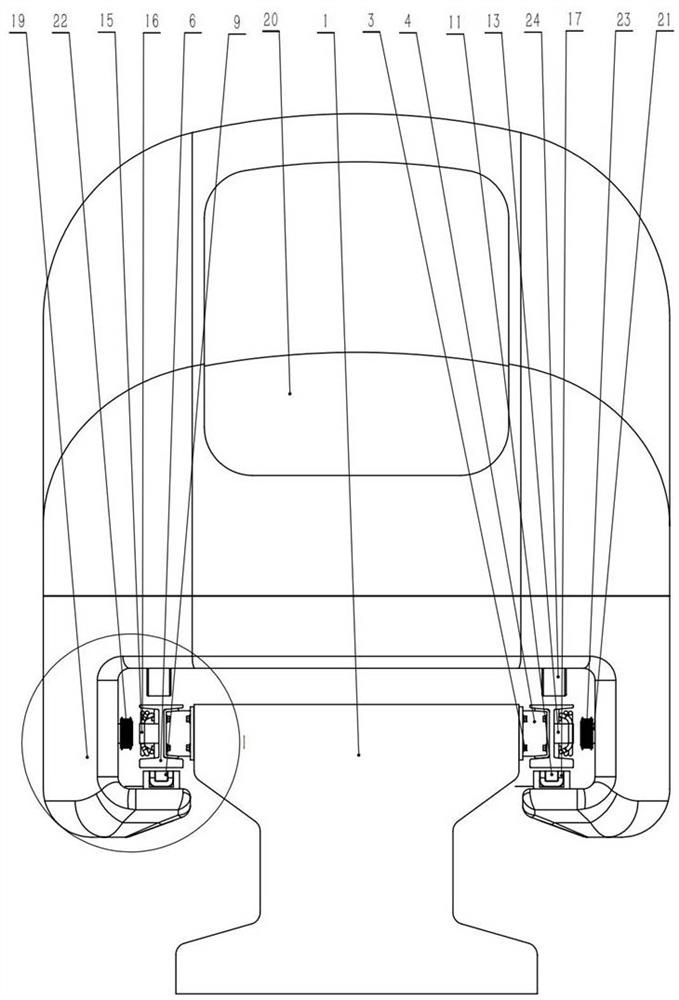

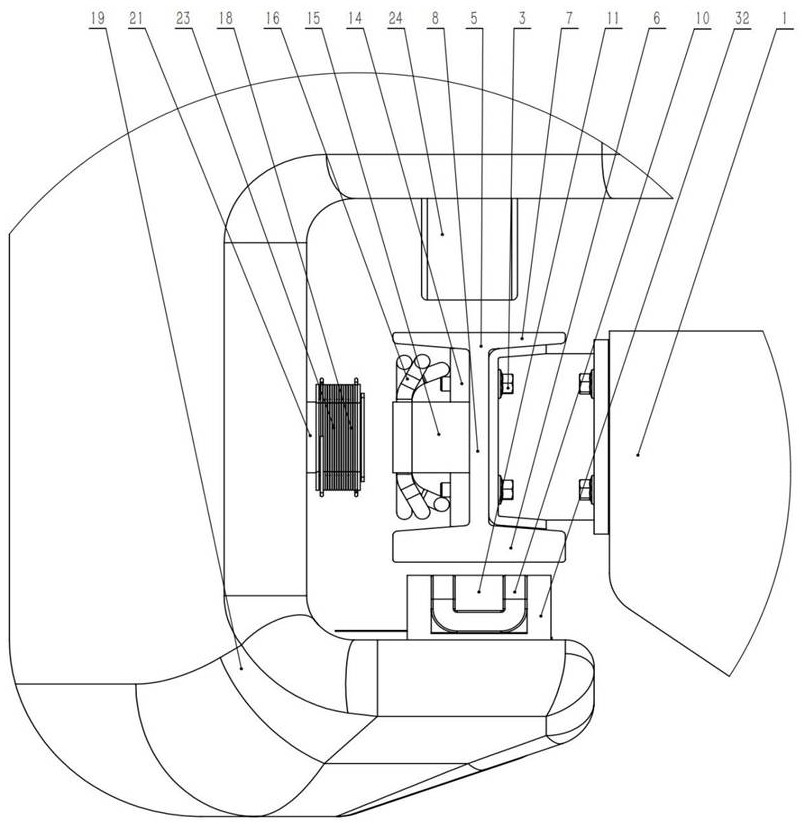

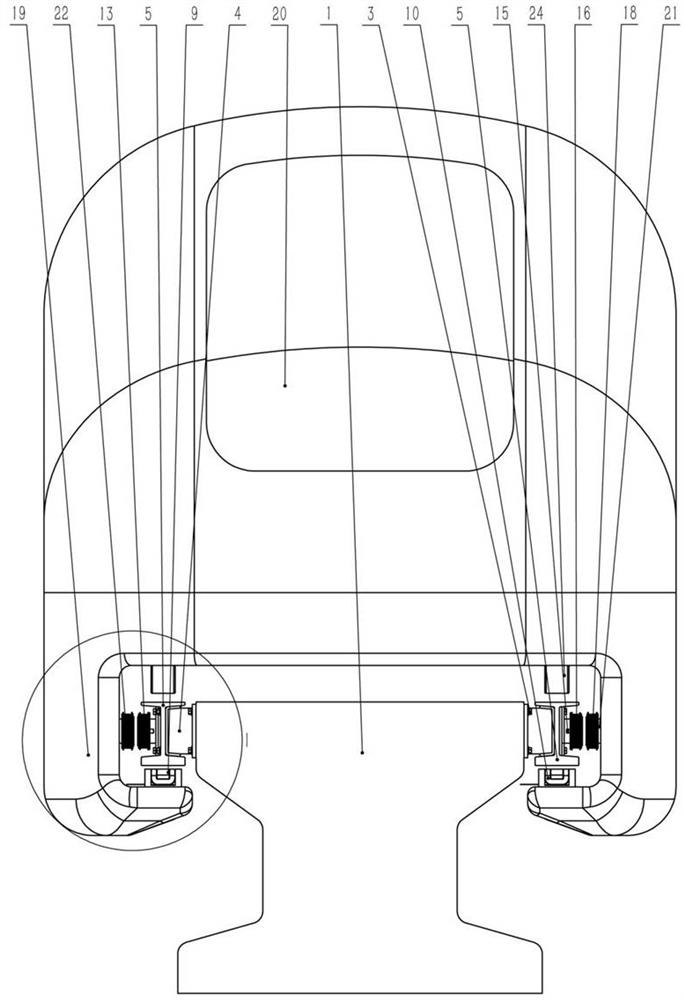

[0076] The present invention is described in further detail now in conjunction with accompanying drawing. Such as figure 1 with figure 2 As shown, it is an electromagnetic levitation train track system of the present invention. Embedded parts are arranged on both sides of the top of the roadbed 1, and track brackets 4 are fixedly arranged on both sides of the embedded parts with fasteners 3, and the extended ends of the track brackets 4 are fixedly connected. The I-shaped steel rail 5, the bottom of the I-shaped steel rail 5 is an armature plate 6, the top of the I-shaped steel rail 5 is a slide plate 7, and the middle is a vertical waist plate 8. The below distance of armature plate 6 is provided with suspending electromagnet 9 in a certain gap, and suspending electromagnet 9 is made of suspending coil 10 and suspending iron core 11, and suspending electromagnet 9 can adopt the electromagnet that can realize the suspending purpose of the present invention in the prior art, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com