A multi-layer tubular busbar structure

A tubular busbar and busbar structure technology, which is applied in the installation of busbars, cooling busbar devices, fully enclosed busbar devices, etc., can solve the problems of layout and arrangement that are difficult to take into account current carrying, heat dissipation, and material saving, etc., to achieve production Mature technology, optimized electric field performance, and flexible splicing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

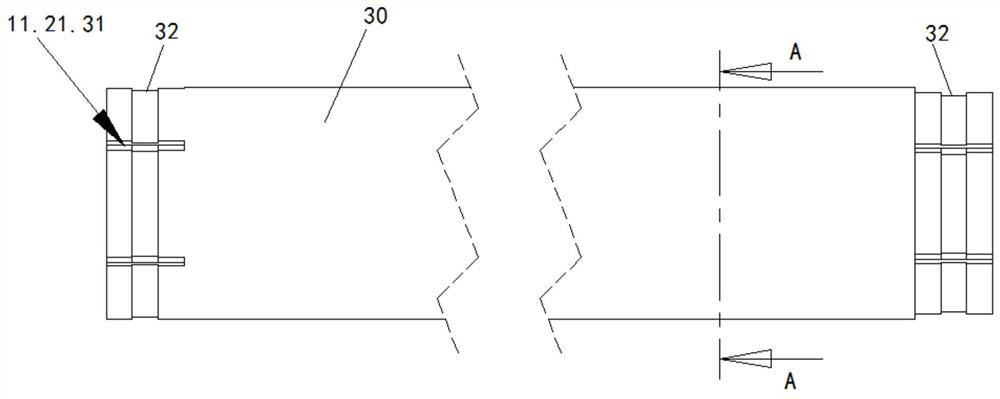

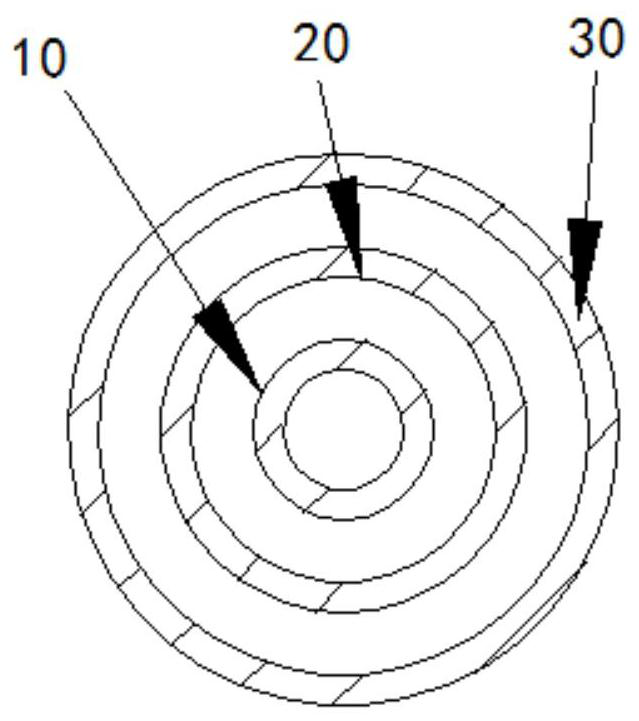

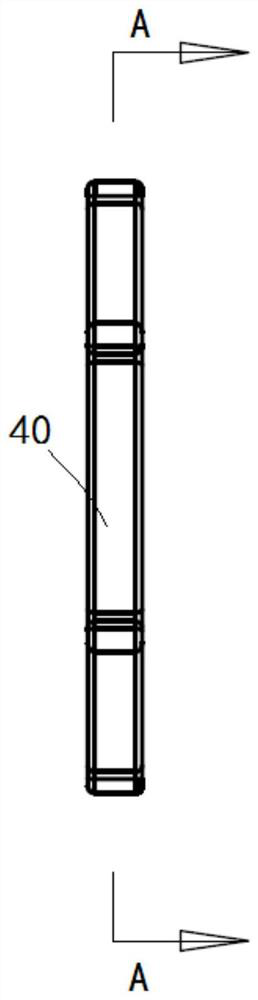

[0028] The multi-layer tubular busbar structure of the present invention is described below by taking the three-layer tubular busbar structure as an example. Of course, the present invention is not limited to the three-layer tubular busbar structure, and can also be a two-layer tubular busbar structure or more than three layers. Tubular busbar structure. The multi-layer linear tubular busbar uses copper tubes of different diameters for multi-layer arrangement. The number of layers can be adjusted from 1 to N layers according to factors such as product application and current-carrying size.

[0029] see figure 1 and figure 2 , The three-layer linear tubular busbar shown in the figure includes three linear tubular busbars arranged from the inside to the outer layer, namely the inner layer linear tubular busbar 10, the middle layer linear tubul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com