Semiconductor cooling and heating composite device and preparation method and application thereof

A composite device and semiconductor technology, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, metal processing equipment, etc., can solve the problems of poor cooling effect, easy loosening of heating wires, and burning of heating wires, etc., to strengthen the fixing effect, improve the Cooling effect, effect of reducing burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

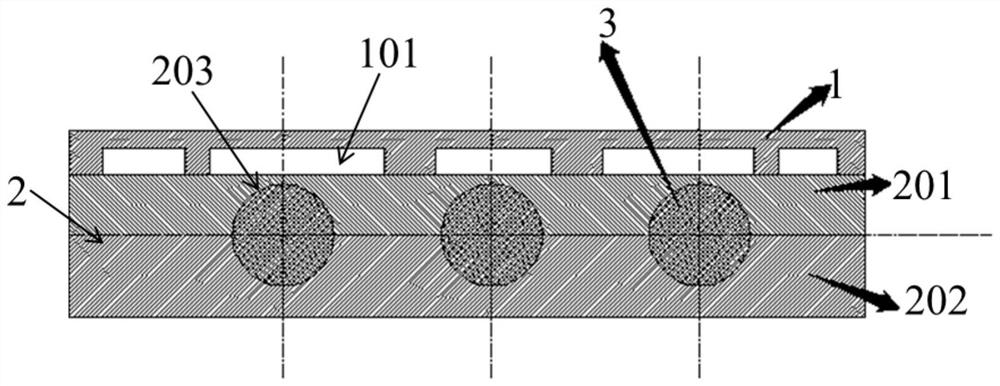

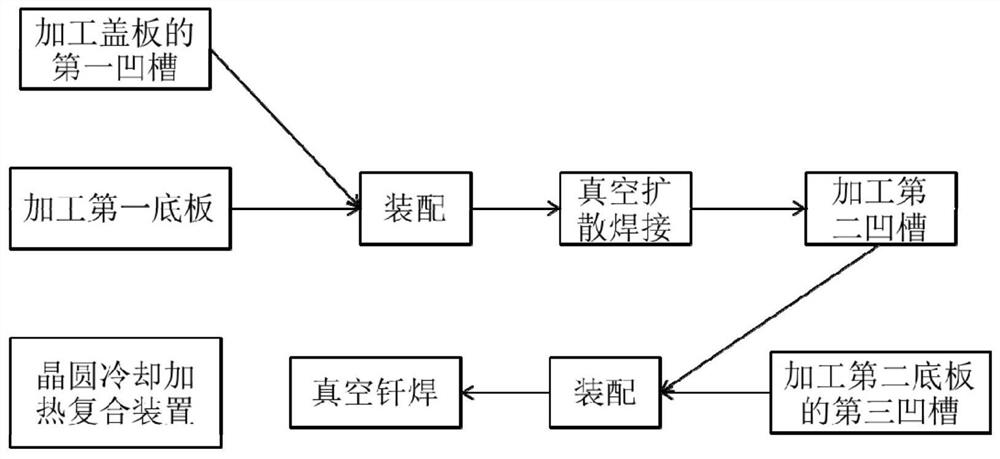

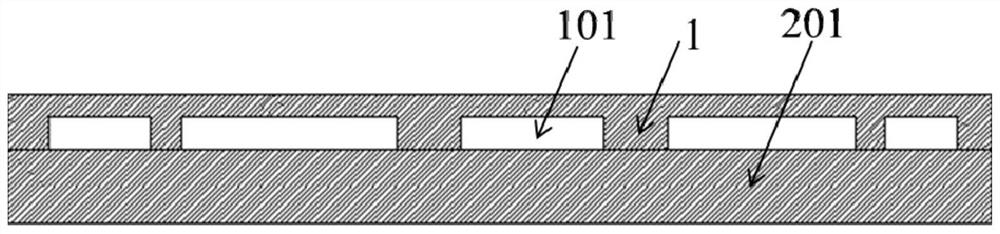

[0079] This embodiment provides a semiconductor cooling and heating composite device, such as figure 1 As shown, the semiconductor cooling and heating composite device includes a cover plate 1 and a bottom plate 2 in turn from top to bottom, the cover plate 1 is provided with at least one first groove 101 opening to the first bottom plate 2012; the bottom plate 2 A slot hole 203 is provided inside, and the slot hole 203 is not in contact with the cover plate 1 , and the slot hole 203 is not in contact with the first groove 101 .

[0080]The bottom plate 2 includes a first bottom plate 2012 and a second bottom plate 2022 sequentially downward from the cover plate 1, and the first bottom plate 2012 is provided with at least one second groove 2031 opening toward the second bottom plate 2022; The bottom plate 2022 is provided with at least one third groove 2032 opening toward the first bottom plate 2012; the second groove 2031 and the third groove 2032 form a circular slot; the se...

Embodiment 2

[0087] This embodiment provides a compound cooling and heating device for semiconductors. The compound cooling and heating device for semiconductors includes a cover plate and a bottom plate sequentially from top to bottom, and at least one first groove opening to the first bottom plate is arranged in the cover plate; A slot is provided inside the bottom plate, and the slot is not in contact with the cover plate, and the slot is not in contact with the first groove.

[0088] The bottom plate includes a first bottom plate and a second bottom plate sequentially from the cover plate downwards, the first bottom plate is provided with at least one second groove opening toward the second bottom plate; At least one third groove of the bottom plate opening; the second groove and the third groove form a circular slot; the second groove is a second semicircular groove; the third groove is a third Semi-circular slot; the radius of the circular slot is 2mm; the flatness of the cover plate...

Embodiment 3

[0095] This embodiment provides a compound cooling and heating device for semiconductors. The compound cooling and heating device for semiconductors includes a cover plate and a bottom plate sequentially from top to bottom, and at least one first groove opening to the first bottom plate is arranged in the cover plate; A slot is provided inside the bottom plate, and the slot is not in contact with the cover plate, and the slot is not in contact with the first groove.

[0096] The bottom plate includes a first bottom plate and a second bottom plate sequentially from the cover plate downwards, the first bottom plate is provided with at least one second groove opening toward the second bottom plate; At least one third groove of the bottom plate opening; the second groove and the third groove form a circular slot; the second groove is a second semicircular groove; the third groove is a third Semi-circular slot; the radius of the circular slot hole is 2.01mm; the flatness of the cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com