Redundant flexible contact point contact inertia switch

An inertial switch and flexible technology, applied in the field of inertial switches, can solve the problems of short closing time, easy breakage or deformation, and low reliability of the switch, and achieve the effect of universal structural design, improving the reliability of action, and prolonging the closing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

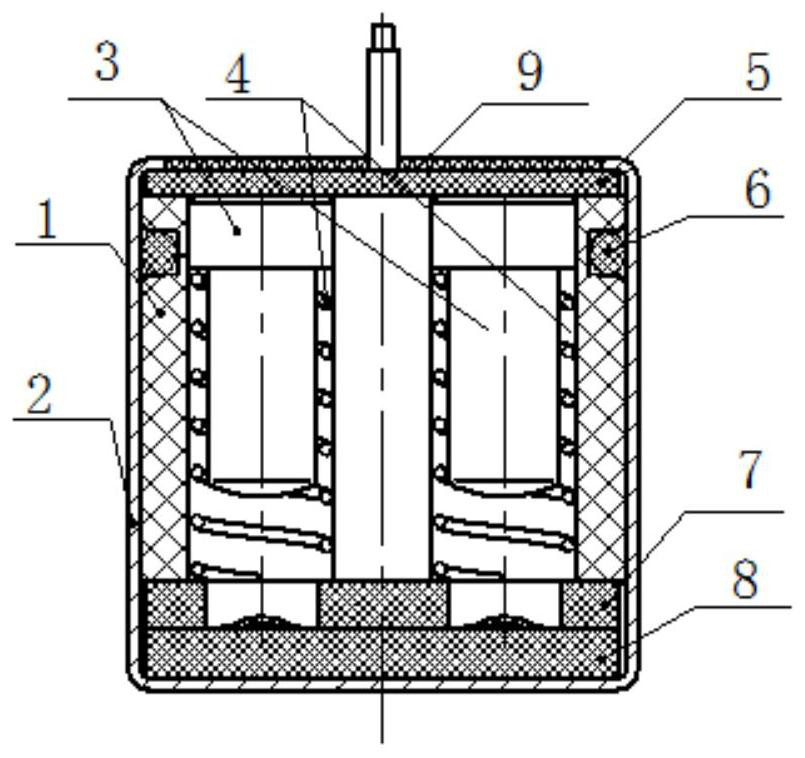

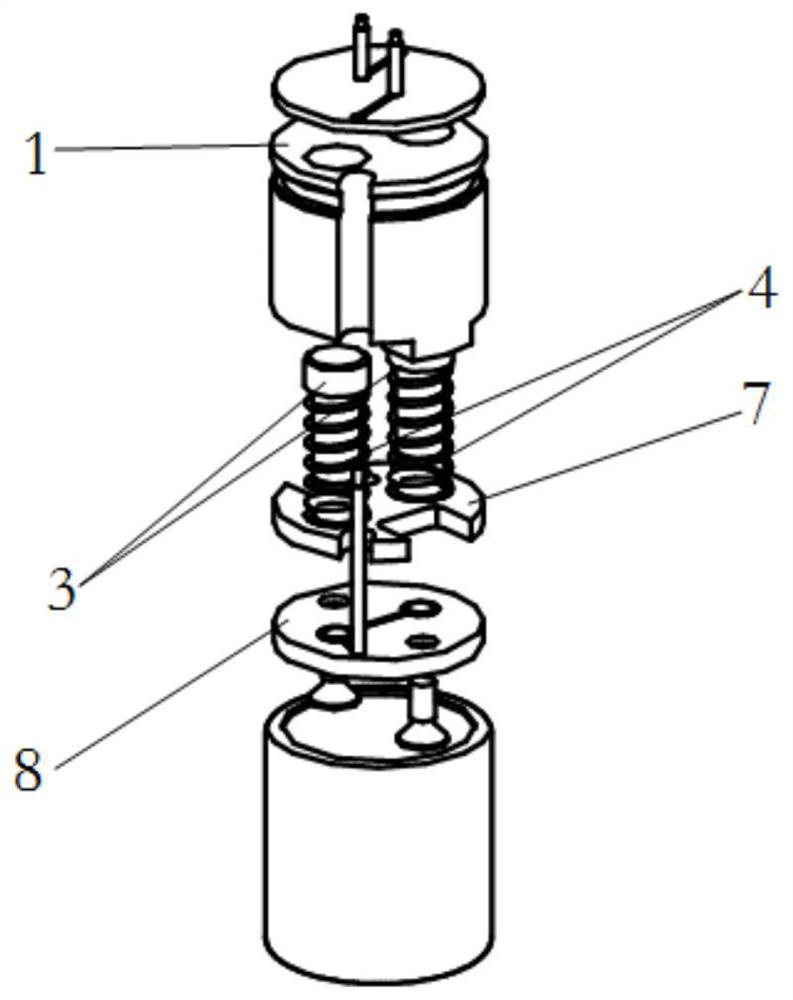

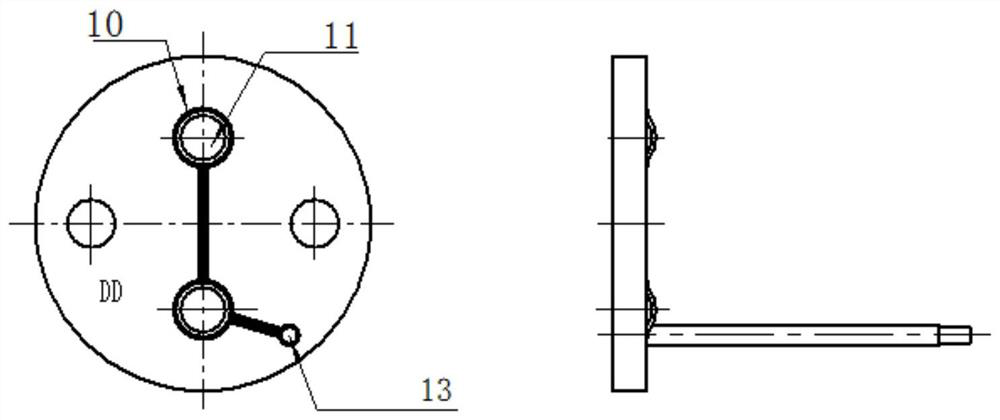

[0036] Such as Figure 1-2 As shown, an inertial switch with redundant flexible contact contact includes an insulating body, a metal shell, two inertia pins, two inertia springs, a lead PCB board, a conductive PCB board and an insulating PCB board, wherein the insulating body, two One inertia pin, two inertia springs, lead PCB board, conductive PCB board and insulating PCB board are all set inside the metal case; lead wire PCB board is located at the top of the metal case; conductive PCB board and insulating PCB board are located at the bottom of the metal case, and The insulating PCB board is located above the conductive PCB board, and the insulating PCB board supports the two inertia springs; the insulating body is distributed on the side of the metal shell to form an inner hole of the insulating body, and the insulating body is located between the lead PCB board and the insulating PCB board; the two Two inertia springs are respectively placed on the two inertia pins to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com