Hydraulic control one-way valve

A hydraulically controlled one-way valve and valve stem technology, applied in the direction of control valves, lift valves, valve devices, etc., can solve the problems of leakage at the joint, difficult to clean, difficult to disassemble, etc., to achieve high joint stability, convenient cleaning, and connection solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

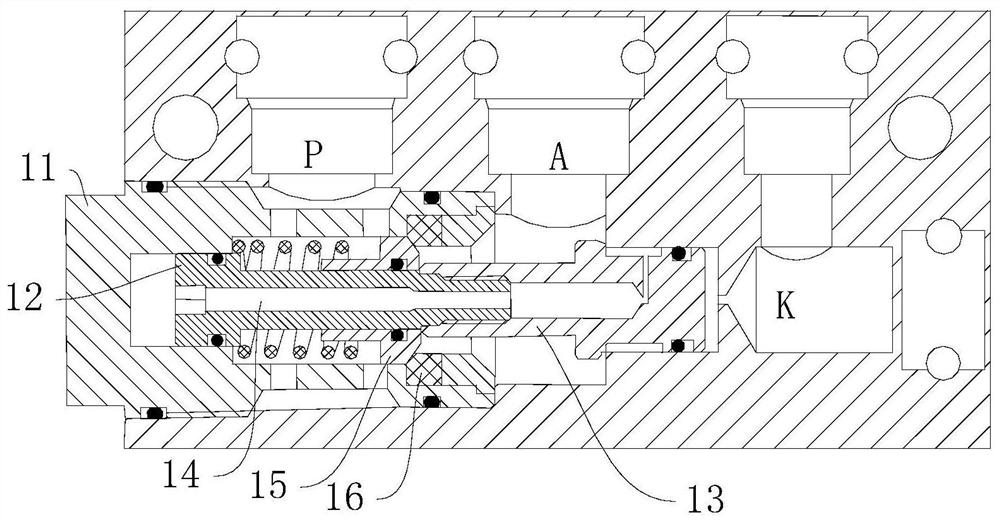

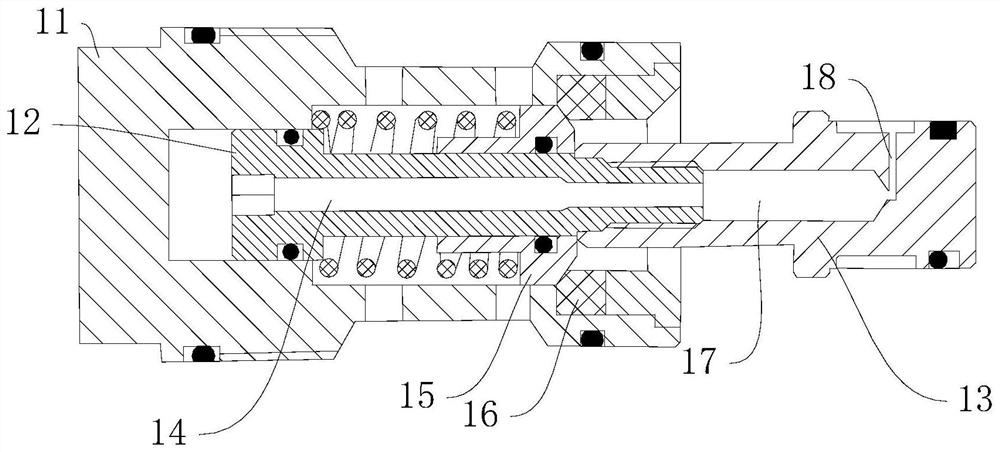

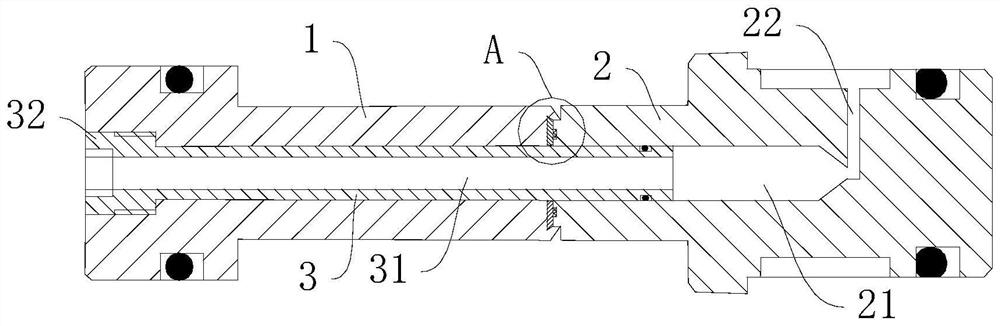

[0030] A hydraulically controlled one-way valve, see attached Figure 3-10 , since this solution only involves the improvement of the valve stem 1 and the control piston 2, the structure of the rest of the parts will not be introduced too much.

[0031] The valve stem 1 includes a communication hole 12 through which the inside passes, and a lock chamber 11 concentric with the communication hole 12 is provided at one end of the valve stem 1 , and a socket end is provided at the other end, and the socket end is used for engaging with the control piston 2 . Wherein the control piston 2 includes a docking hole 21 matched with the connecting hole, and the docking hole 21 does not pass through the control piston 2 , and the diameter of the docking hole 21 is consistent with that of the communication hole 12 . The peripheral surface of the control piston 2 is also provided with a throttling hole 22 communicating with the docking hole 21, and the throttling hole 22, the docking hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com