Method for operating injection device of internal combustion engine, injection device and internal combustion engine

A technology of injection device and internal combustion engine, applied in the fields of direct injection device, injection device and internal combustion engine, can solve problems such as unoptimized consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

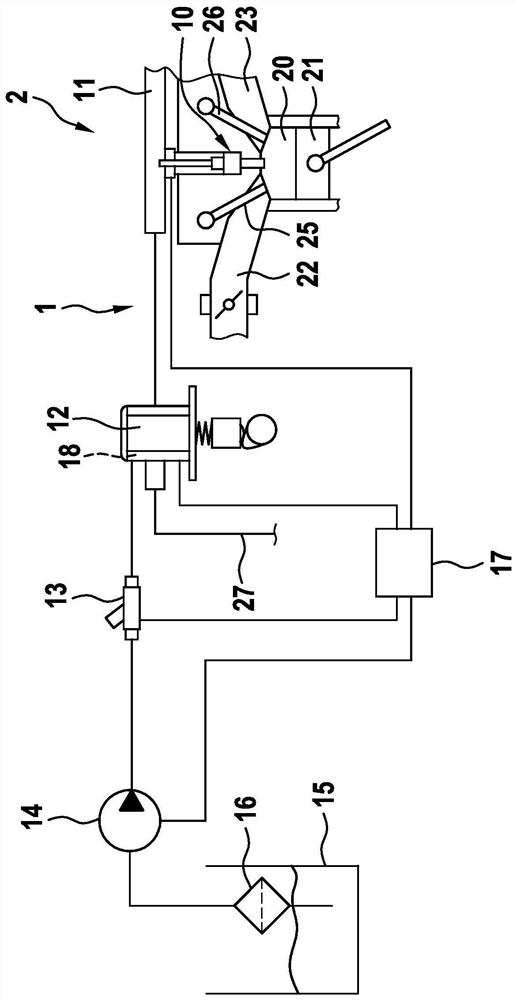

[0019] Refer below figure 1 and 2 An injection system 1 of an internal combustion engine 2 and a method for operating the injection system 1 according to a preferred exemplary embodiment of the invention will be described in detail.

[0020] In this exemplary embodiment, the internal combustion engine 2 has a plurality of cylinders. For a better overview, the figure 1 Only one cylinder is shown. However, the following descriptions regarding the construction of the internal combustion engine 2 apply to all cylinders.

[0021] as from figure 1 It can be seen that the internal combustion engine 2 or the cylinder comprises a combustion chamber 20 in which a piston 21 can move back and forth. Furthermore, the internal combustion engine 2 has an intake duct 22 via which air can be supplied to the combustion chamber 20 . For this purpose, an inlet valve 25 is provided, which releases or closes the inlet channel 22 . The exhaust gas is discharged via the exhaust gas passage 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com