Wind-pressure-resistant door for coastal areas

A wind pressure-resistant, coastal technology, applied in the field of doors and windows, can solve the problems of easy noise generation, easy movement between the door and the door frame, door collision, etc., to reduce the impact force, strengthen the noise reduction effect, and increase the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

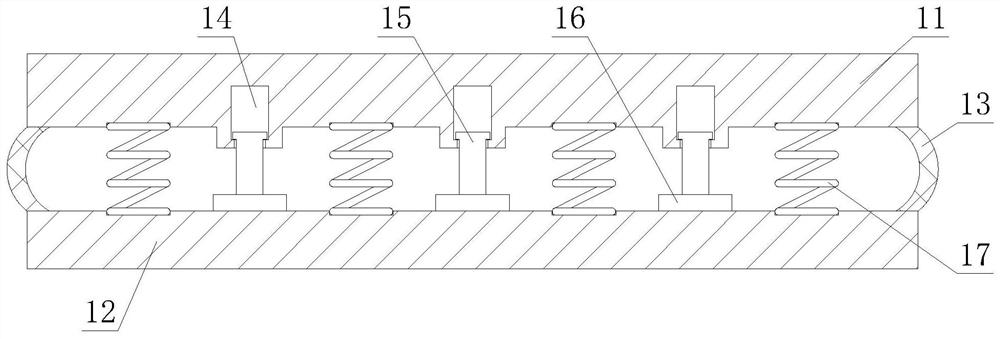

[0025] Such as figure 1 - figure 2 As shown, the present invention provides a wind pressure-resistant door in coastal areas, including a door body 1, a door lock 2 is arranged in the middle of one side of the door body 1, and a connecting plate 11 and a wind pressure plate 12 are arranged inside the door body 1. A rubber strip 13 is fixedly connected to the outer edge between the connection plate 11 and the air pressure plate 12, and a spring 17 is arranged between the connection plate 11 and the air pressure plate 12, and the spring 17 is used to reset the air pressure plate 12, and the connection plate 11 is close to One side of the air pressure plate 12 is provided with a connecting groove 14, the inside of the connecting groove 14 is slidably connected with a sliding block 15, and the end of the sliding block 15 away from the connecting groove 14 is fixedly connected with a shock absorbing block 16, and the shock absorbing block 16 is far away from the side of the sliding...

Embodiment 2

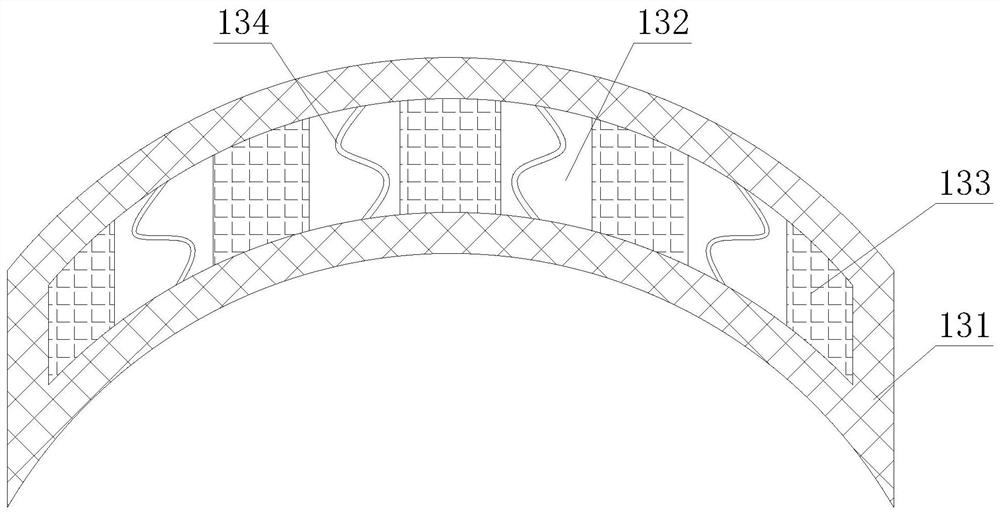

[0028] Such as image 3 As shown, on the basis of Example 1, the present invention provides a technical solution: the inside of the rubber strip 13 is provided with a sealing layer 131, the inside of the sealing layer 131 is provided with an inner cavity 132, and the inner cavity 132 is fixedly connected with a sponge Blocks 133 and elastic sheets 134, and sponge blocks 133 and elastic sheets 134 are arranged alternately.

[0029] In this embodiment, the setting of the sponge block 133 can absorb the vibration generated when the sealing layer 131 contacts the door frame, so as to reduce the noise. The block 133 absorbs the vibration to achieve further noise reduction. Through the setting of the elastic piece 134, the force received by the sealing layer 131 can be further absorbed, so that the noise reduction effect is further strengthened, and through the setting of the elastic piece 134, it can be reset. , propping up the inside of the sealing layer 131 so that the sealing l...

Embodiment 3

[0031] Such as Figure 4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the inside of the sliding block 15 is provided with a limit rod 151, and the upper end of the limit rod 151 is fixedly connected with a slowing rubber 152. The inside is provided with a cavity 153, and both sides of the upper end of the limit rod 151 are movably connected with an arc-shaped rubber block 154. One end of the position rod 151 is designed to be inclined downward.

[0032] In this embodiment, through the setting of the slowing rubber 152, the slowing rubber 152 can be deformed through the internal cavity 153, so as to convert the impact force and reduce the impact force, so as to reduce the impact force on the connecting plate 11, so as to increase The service life of the present invention, through the design of the arc-shaped rubber block 154, when the sliding block 15 moves away from the shock-absorbing block 16, the arc-shaped rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com