A kind of manufacturing process of lavender silk quilt

A production process, silk quilt technology, applied in the field of textile processing, can solve the problems of uncomfortable use of quilts, effective treatment without cocoons, etc., and achieve the effects of comfortable use, increased efficiency, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

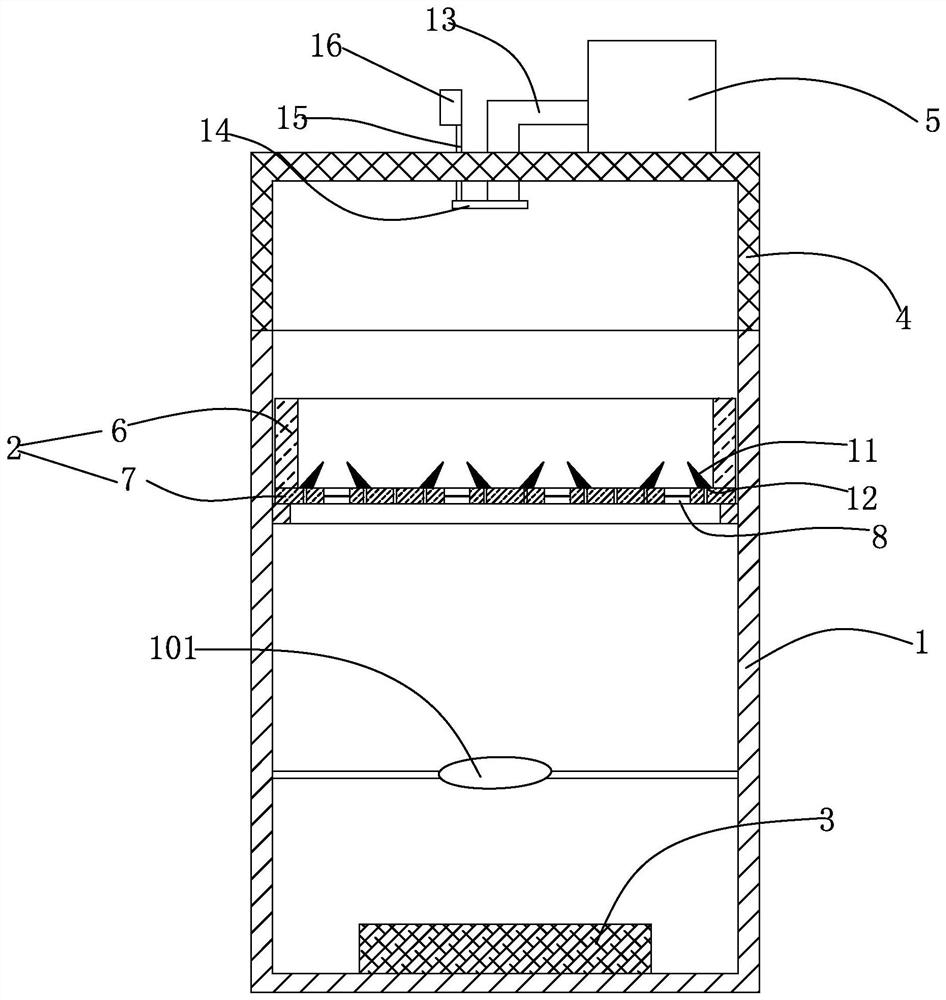

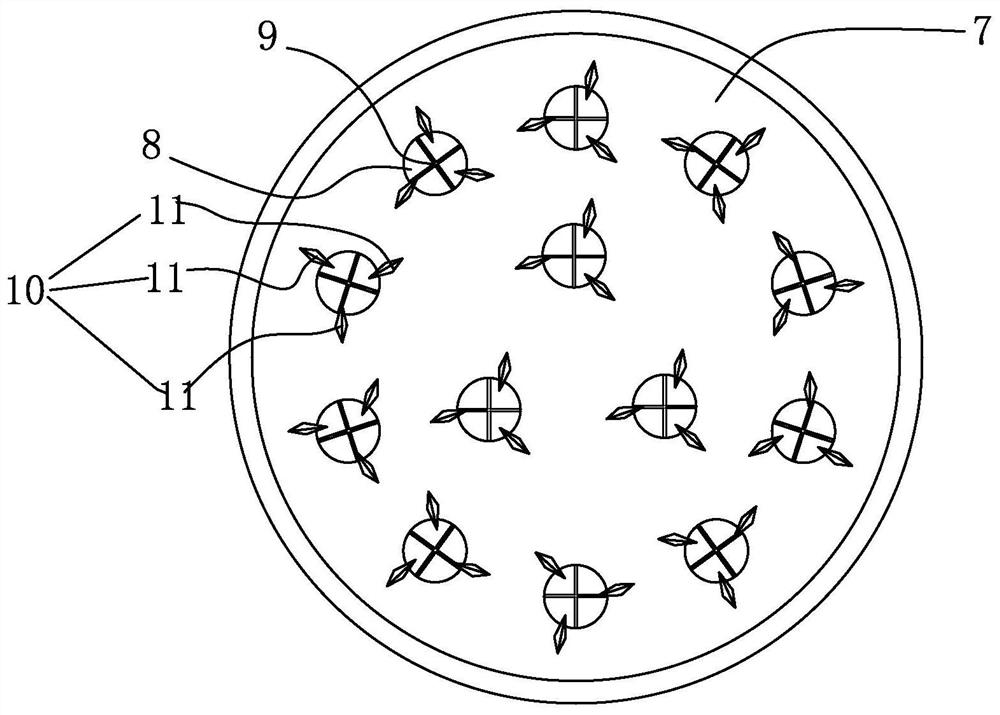

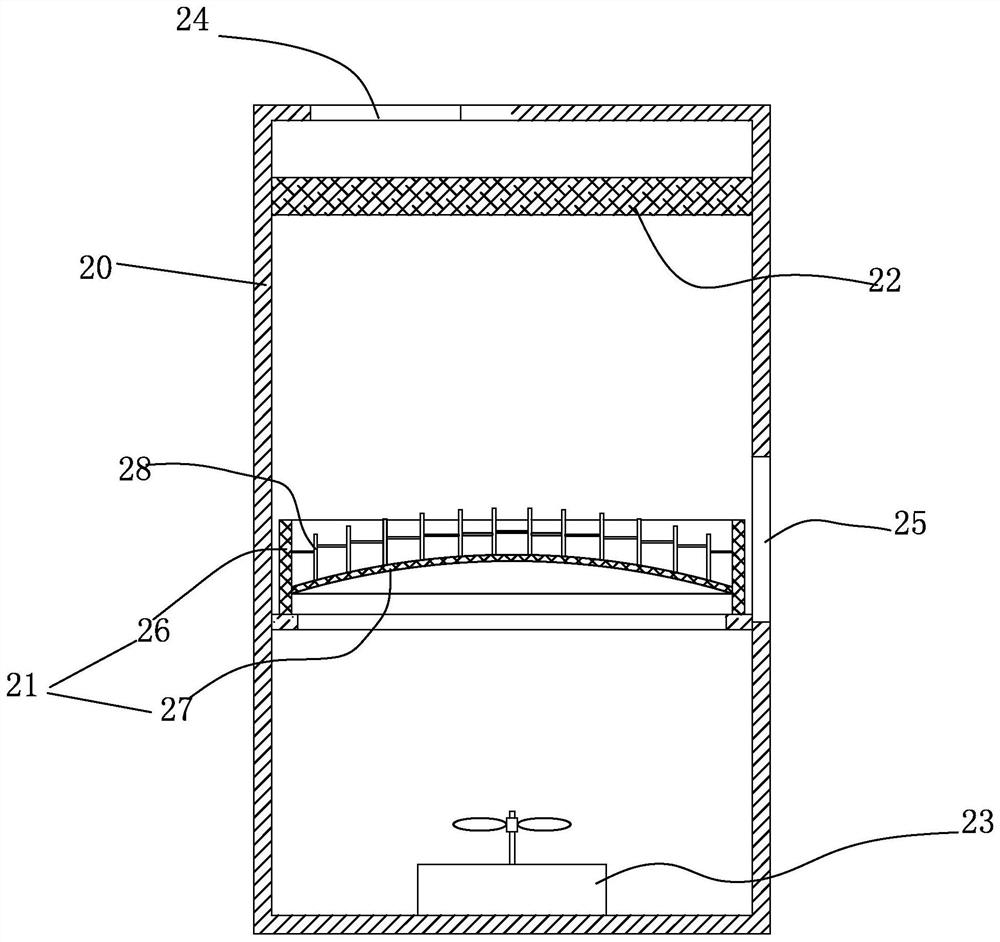

[0029] refer to Figure 1 to Figure 4 The embodiments of the present invention will be further described.

[0030] The invention relates to a manufacturing process of the lavender silk quilt which no longer has the smell of silkworm cocoons after processing.

[0031] Specific embodiments of the present invention: a kind of manufacture craft of lavender silk quilt, through following steps successively:

[0032] S1. Selecting cocoons, manually selecting double cocoons, and drying the selected double cocoons with a drying device to become dry cocoons;

[0033] S2, boil the cocoon, put the dried cocoon into the water of 25°-35°, and add baking soda accounting for 2% of the water weight in the water, and cook for 60-75 minutes;

[0034] S3, cocoon steaming, the cooked cocoons are placed in a deodorizing device for steaming, and a lavender material bag 101 is provided in the deodorizing device;

[0035] S4, soaking, soaking the cooked silkworm cocoons in clear water, and cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com