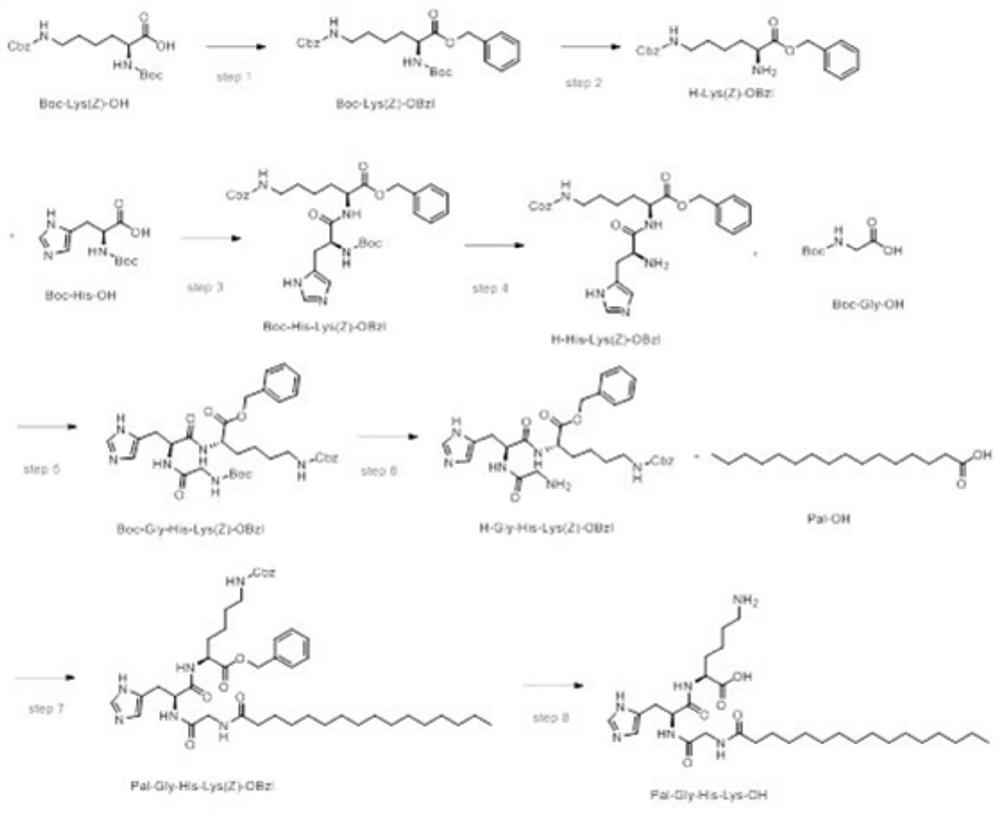

Liquid-phase synthesis method of palmitoyl tripeptide-1

A technology of palmitoyl tripeptide and liquid phase synthesis, which is applied in the field of polypeptide preparation, can solve the problems of being unsuitable for large-scale production, prolonging the process cycle, and prone to explosion, etc., and achieves environment-friendly production conditions, simple process route, and mild reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Synthesis of Boc-Lys(Z)-OBzl

[0038] Start stirring and pump in 20L of acetone, add Boc-Lys(Z)-OH10kg, add potassium carbonate 3.81kg, add Bzl-Br4.72kg and stir for reaction. The reaction time is about 3h. If there is no raw material point on the TLC plate, it is judged that the reaction is over. Use vacuum pumping Add 20L of water, add 20L of ethyl acetate to extract twice, combine the organic phase into 20L of water, wash twice, wash once with 20L of saturated saline, add anhydrous sodium sulfate to the organic phase, dry, filter, rinse with ethyl acetate, and spin dry used directly in the next reaction.

[0039] (2) Synthesis of H-Lys(Z)-OBzl

[0040] Connect to the first step reactor and continue to operate, turn on the stirring, pump in DCM30L, weigh MS-OH3.03kg and add it, stir evenly and release it into the bucket, let it stand for reaction, the reaction time is about 2h, HPLC monitoring determines that the reaction is over, directly drop step.

[0041] (...

Embodiment 2

[0055] (1) Synthesis of Boc-Lys(Z)-OBzl

[0056] Start stirring and pump in DMF20L, add Boc-Lys(Z)-OH10kg, add cesium carbonate 11.2kg, add Bzl-Br4.58kg and stir for reaction. The reaction time is about 4h. If there is no raw material point on the TLC plate, it is judged that the reaction is over. Use vacuum to pump water 20L, add 20L of ethyl acetate to extract twice, merge the organic phase into 20L of water and wash twice, wash once with 20L of saturated saline, add anhydrous sodium sulfate to the organic phase to dry, filter, rinse with ethyl acetate, spin dry and directly for the next reaction;

[0057] (2) Synthesis of H-Lys(Z)-OBzl

[0058] Connect to the first step reaction kettle and continue to operate, start stirring, pump in THF35L, weigh MS-OH3.05kg and add it, stir evenly and release it into the barrel, let it stand at room temperature for reaction, the reaction time is about 3h, HPLC monitoring determines the end of the reaction, Directly vote for the next ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com