Novel ceramsite and preparation method thereof

A new technology of ceramsite, which is applied in the field of building materials, can solve the problems of ceramsite preparation, no compounding, poor swelling performance, etc., and achieve the effect of reducing production cost, improving utilization rate, and hard shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

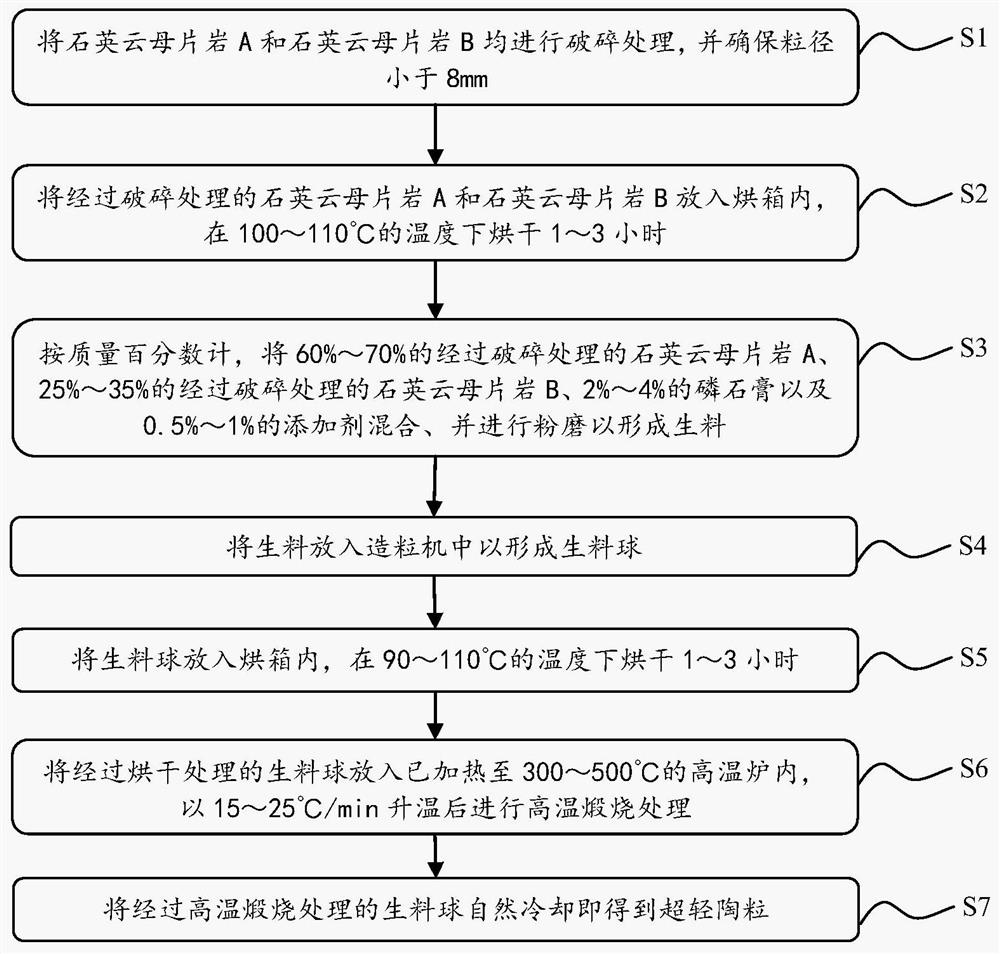

[0038] The present invention also provides a kind of preparation method of novel ceramsite, described preparation method is used for preparing described novel ceramsite, comprises:

[0039] S1: Crushing both the quartz mica schist A and the quartz mica schist B, and ensuring that the particle size is less than 8mm;

[0040] S2: put the crushed quartz-mica schist A and quartz-mica schist B into an oven, and dry at a temperature of 100-110° C. for 1-3 hours;

[0041] S3: In terms of mass percentage, 60% to 70% of crushed quartz mica schist A, 25% to 35% of crushed quartz mica schist B, 2% to 4% of phosphogypsum and 0.5% to 1% additives are blended and ground to form a raw meal:

[0042] S4: Put the raw meal into the granulator to form raw meal balls;

[0043] S5: put the raw meal balls into an oven, and dry at a temperature of 90-110°C for 1-3 hours;

[0044] S6: Put the dried raw meal balls into a high-temperature furnace heated to 300-500°C, heat up at 15-25°C / min, and then...

Embodiment 1

[0052] S1: Crushing both the quartz mica schist A and the quartz mica schist B, and ensuring that the particle size is less than 8mm;

[0053] S2: put the crushed quartz-mica schist A and quartz-mica schist B into an oven, and dry at a temperature of 105° C. for 2 hours;

[0054] S3: In terms of mass percentage, 70% of crushed quartz mica schist A, 26.5% of crushed quartz mica schist B, 3% of phosphogypsum and 0.5% of silicon carbide powder were mixed and ground To form raw meal:

[0055] S4: Put the raw meal into the granulator to form raw meal balls;

[0056] S5: put the raw meal balls into an oven, and dry them at a temperature of 105°C for 2 hours;

[0057] S6: Put the dried raw meal balls into a high-temperature furnace heated to 300°C, heat up at 20°C / min, and then perform high-temperature calcination, and the temperature for calcination is 1240°C, and the time is 10 minutes;

[0058] S7: Naturally cool the raw material balls that have been calcined at high temperatur...

Embodiment 2

[0060] S1: Crushing both the quartz mica schist A and the quartz mica schist B, and ensuring that the particle size is less than 8mm;

[0061] S2: put the crushed quartz-mica schist A and quartz-mica schist B into an oven, and dry at a temperature of 105° C. for 2 hours;

[0062] S3: In terms of mass percentage, 61.5% of crushed quartz mica schist A, 35% of crushed quartz mica schist B, 3% of phosphogypsum and 0.5% of aluminum powder were mixed and ground to obtain Form raw meal:

[0063] S4: Put the raw meal into the granulator to form raw meal balls;

[0064] S5: put the raw meal balls into an oven, and dry them at a temperature of 105°C for 2 hours;

[0065] S6: Put the dried raw meal balls into a high-temperature furnace heated to 300°C, heat up at 20°C / min, and then perform high-temperature calcination, and the temperature for calcination is 1250°C, and the time is 15 minutes;

[0066] S7: The new type of ceramsite can be obtained by natural cooling of the raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com