Sewage treatment device and sewage treatment assembly

A sewage treatment device and sewage treatment technology, applied in the direction of oxidized water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Sewage treatment costs and other issues, to achieve a high degree of automation, avoid clogging, and reduce labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

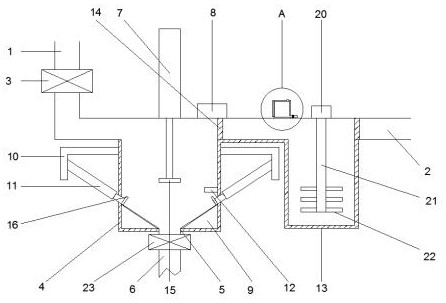

[0027] Example 1 as figure 1 As shown, a sewage treatment device and a sewage treatment assembly according to an embodiment of the present invention include a water inlet pipe 1 and an outlet pipe 2, the water inlet pipe 1 is equipped with a first electromagnetic valve 3, the water inlet pipe 1 is connected to the first box body 4, The outer wall of the lower end of the first box body 4 is provided with a sewage outlet 5, the sewage outlet 5 is connected with a sewage pipe 6, and the sewage pipe 6 is equipped with a second electromagnetic valve 23, and the outer wall of the upper end of the first box body 4 is embedded with a valve that matches the sewage outlet 5. The first electric push rod 7, the outer wall of the upper end of the first box body 4 is fixedly provided with a controller 8, the two ends of the inner wall below the first box body 4 are fixedly provided with symmetrical triangular blocks 9, and the outer walls of the first box body 4 both sides are fixedly provid...

Embodiment 2

[0029] Embodiment 2 is on the basis of embodiment 1 such as figure 1 As shown, for the grid, the connection between the first box body 4 and the water pipe and the connection between the second box body 13 and the water outlet pipe 2 are fixed with a grid 14 .

[0030] Through the above solution of the present invention, the water flow velocity can be changed and some larger impurities can be filtered.

Embodiment 3

[0031] Embodiment 3 is such as on the basis of embodiment 1 figure 1 As shown, for the polytetrafluoroethylene coating, the upper surface of the triangular block 9 is coated with polytetrafluoroethylene coating.

[0032] Through the above solution of the present invention, it is possible to avoid the clogging of the sewage outlet 5 and effectively reduce the sludge adhering to the hypotenuse of the triangular block 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com