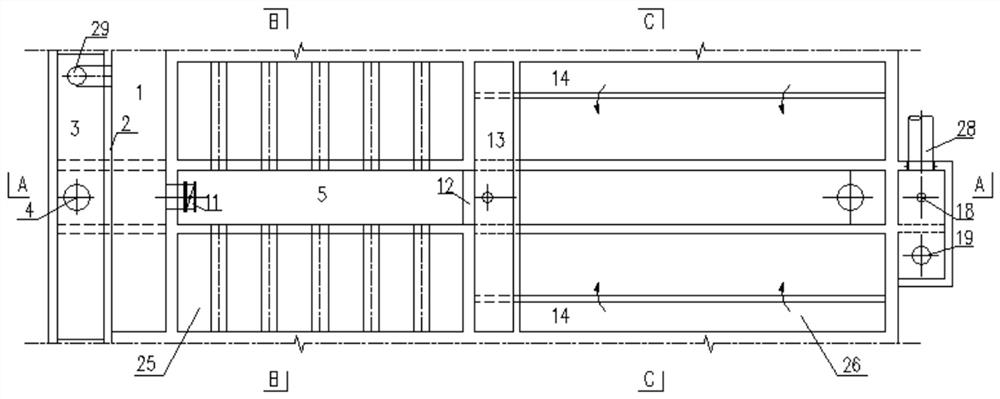

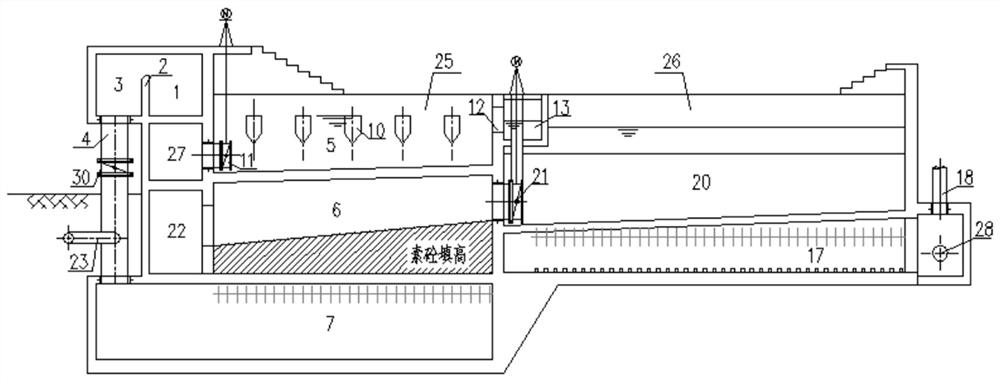

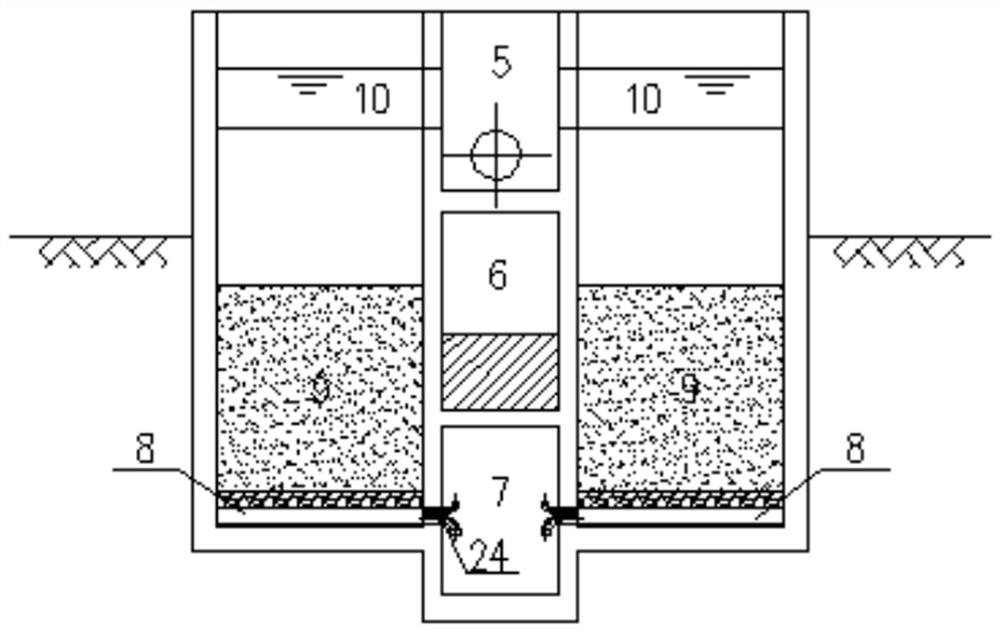

Carbon-sand double filter tank with central canals

A carbon sand and filter technology, which is applied in filtration treatment, special treatment targets, water/sludge/sewage treatment, etc., can solve the problems of poor combination of treatment process pools, difficulty in uniform water distribution, lack of pool structure, etc. , to achieve the effect of reasonable and feasible pool type combination, small water head loss, saving operating costs and water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0035] When the influent water quality is better, it can go beyond the charcoal pool 25 and directly enter the sand pool 26 for processing. The carbon-sand double filter tank has reserved the layout space for the surpassing facilities. When there is a demand for surpassing in practical applications, a sand tank surpassing the water inlet main channel 32 and a single surpassing water inlet valve can be added on the upper side wall of the sand tank 26. 33 and beyond the water inlet weir 34, the incoming water can go beyond the charcoal pond 25 and directly enter the sand pond 26 for processing.

[0036] During water treatment, close the water inlet electric butterfly valve 30, and the water to be treated enters the transcending water inlet main canal 32 through the transcending water inlet pipe 31, and enters the single lattice sand tank 26 through the single lattice surpassing water inlet valve 33 and the surpassing water inlet weir 34, It passes through the sand filter materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com