A kind of automatic material reclaiming method and system based on raw material field scanning imaging

A technology of automatic material retrieving and field scanning, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of high labor intensity of operators, potential safety hazards, and harsh working environment, so as to reduce manual labor intensity and reduce labor costs. Labor cost, the effect of improving production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 of the present invention provides an automatic reclaiming system based on raw material field scanning and imaging, and the automatic reclaiming system includes:

[0049] The image acquisition device is arranged on both sides of the boom of the reclaimer, and is used for collecting and acquiring the point cloud image data of the material pile, and extracting the three-dimensional point cloud model of the material pile in the point cloud image data of the material pile;

[0050] The stack height calculation module is used to obtain the stack height through point cloud merging, denoising, segmentation and fitting of the 3D point cloud model of the stack;

[0051] The layering module is used to layer the stack height according to the preset reclaiming process strategy;

[0052] The control parameter calculation module is used to calculate the operation control parameters of the reclaimer according to the layered 3D point cloud model;

[0053] The controller is...

Embodiment 2

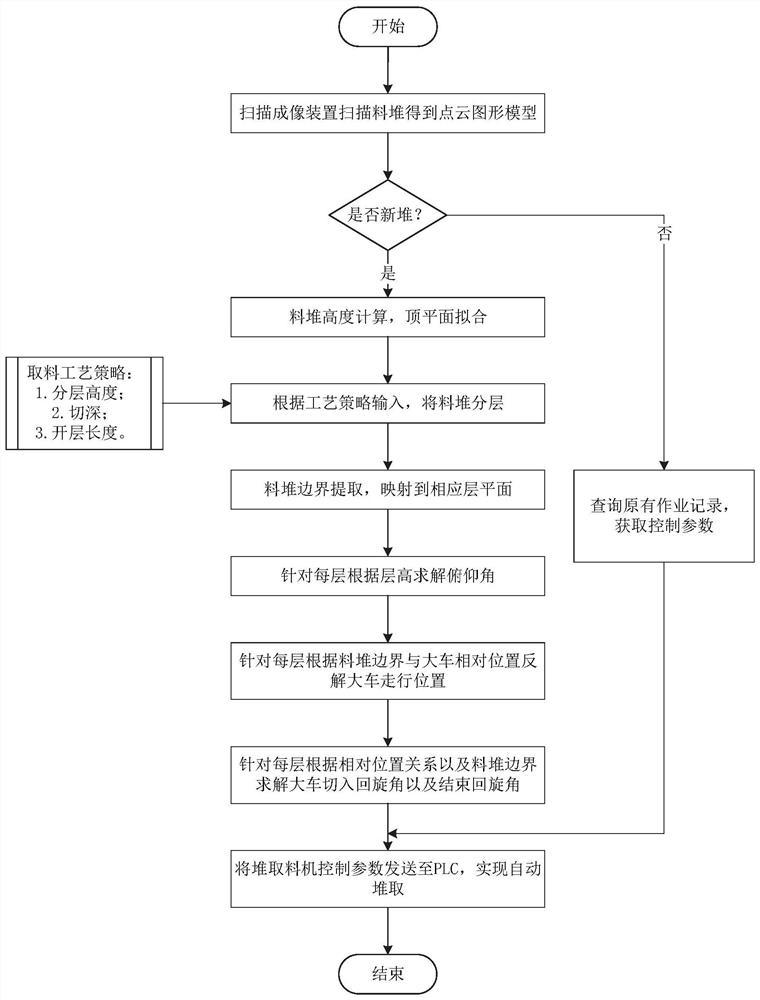

[0074] like figure 1 As shown, this embodiment 2 provides an automatic material reclaiming method based on scanning and imaging of a raw material field. The premise of realization is to obtain a model of the material pile. Before the operation, a scanning imaging device is used to obtain a point cloud image of the material pile. After obtaining the point cloud image data of the material pile, it is necessary to first determine whether the material pile is a new pile. If it is a new pile, it is necessary to calculate the control parameters of the stacker and reclaimer according to the point cloud image data of the material pile. Secondary operation records, no need to recalculate stacker-reclaimer control parameters, improve efficiency. After extracting the point cloud data model of the discharge pile, the pile height can be obtained through point cloud merging, denoising, segmentation and fitting processing. According to the existing reclaiming process parameters, the pile hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com