Packaging machine

A packaging machine and main body technology, which is applied in the field of pharmaceutical granule packaging, can solve the problems that the packaging machine cannot quantitatively determine the size of the packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

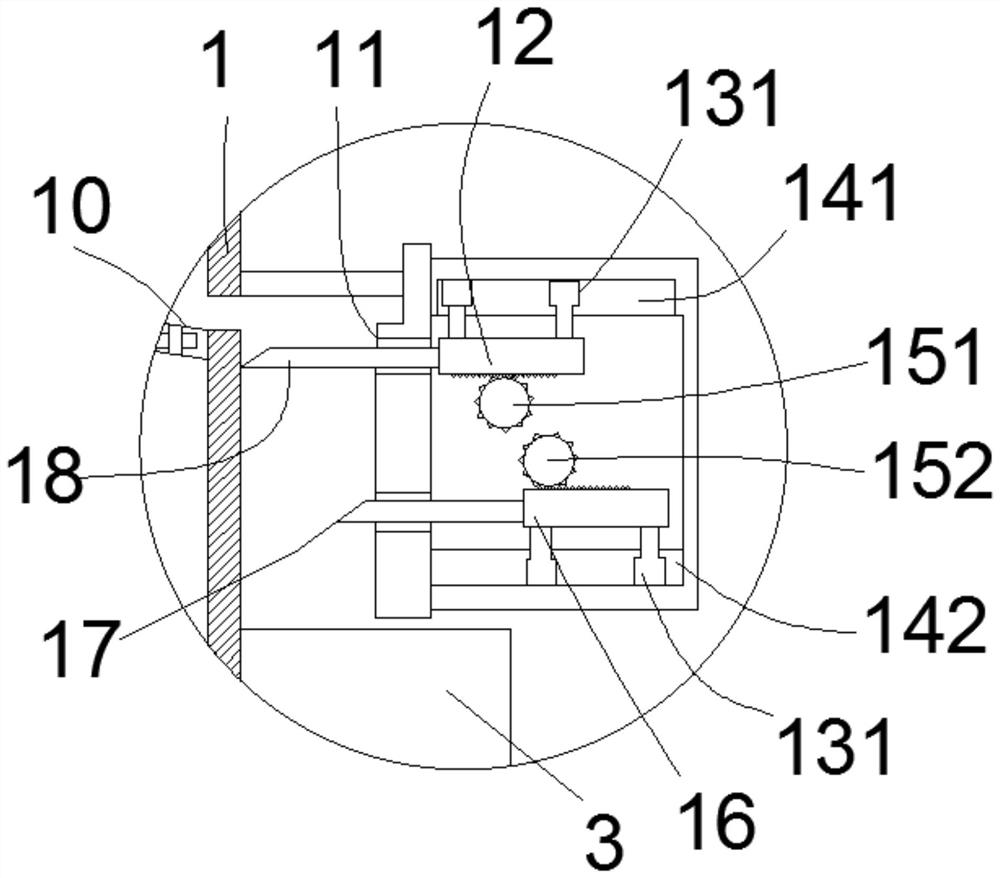

[0023] A packaging machine, comprising: a main body 1 of the packaging machine, a sieve plate 9 and a baffle plate 10 are arranged in the main body 1 of the packaging machine, the sieve plate 9 is arranged obliquely, and a feeding mechanism is arranged at the end of the sieve plate 9, and the feeding mechanism includes The first toothed plate 151, the second toothed plate 152, the upper toothed plate 12 and the lower toothed plate 16, the first toothed plate 151 is fixedly connected to the output end of the motor one, the second toothed plate 152 is fixedly connected to the output end of the second motor, and the upper toothed plate 12 It meshes with tooth plate one 151, and the lower tooth plate 16 meshes with tooth plate two 152. One end of the upper tooth plate 12 is fixedly connected with an upper cutter 18, and one end of the lower tooth plate 16 is fixedly connected with a lower cutter 17. The motor body one drives the tooth plate one 151 to rotate, so that the tooth plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com