Damping type building mortar stirring equipment

A mortar mixing and equipment technology, applied in mechanical equipment, springs/shock absorbers, cement mixing devices, etc., can solve the problems of inapplicability and large amount of manual mixing operations, and achieve the effect of avoiding uneven quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

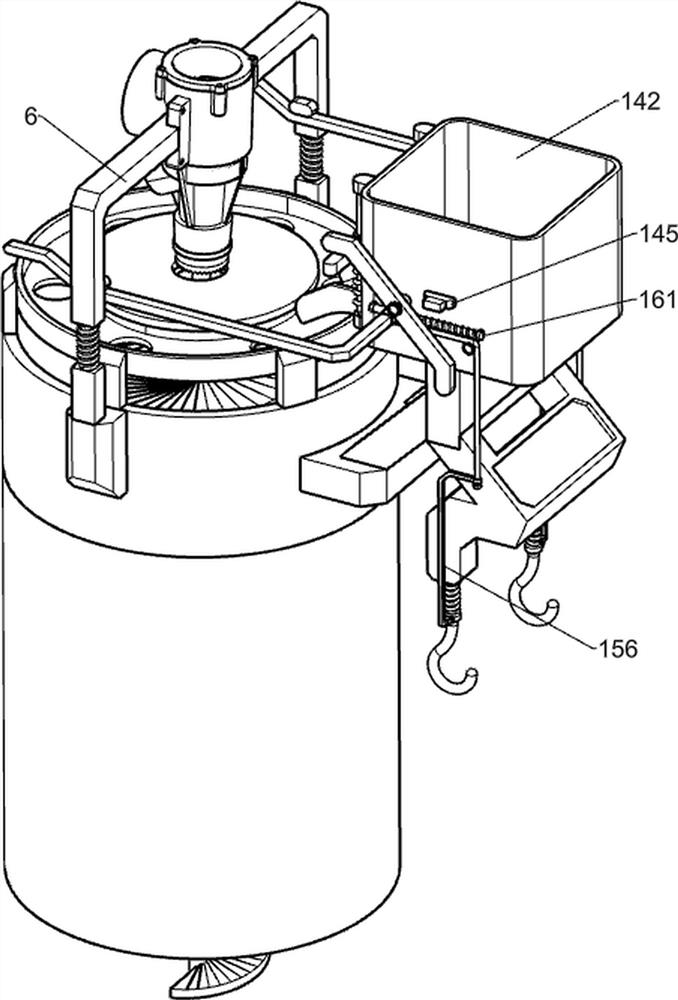

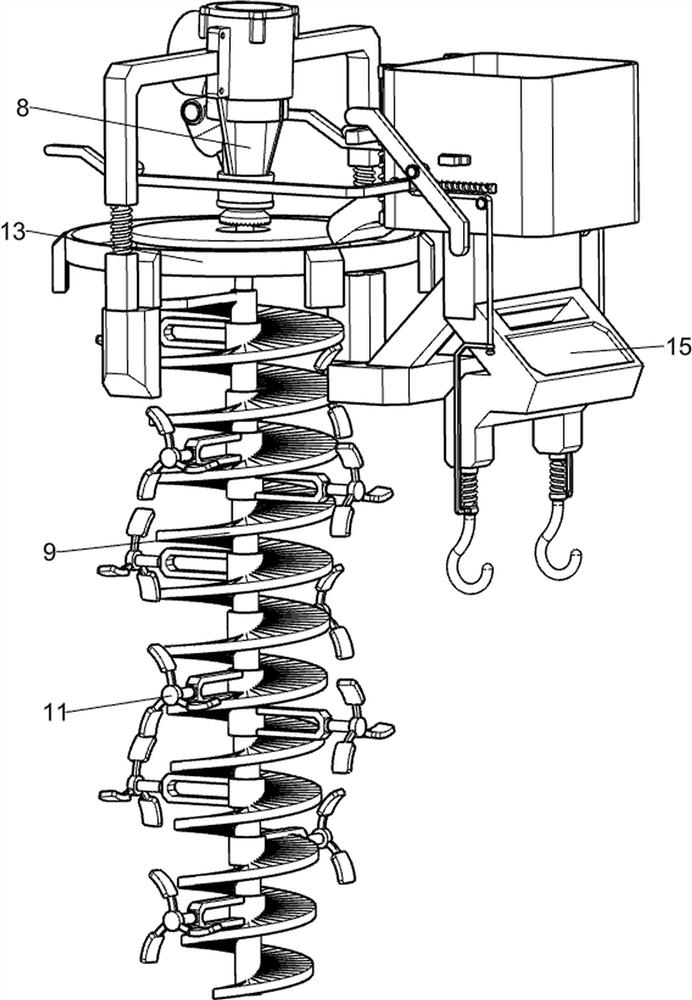

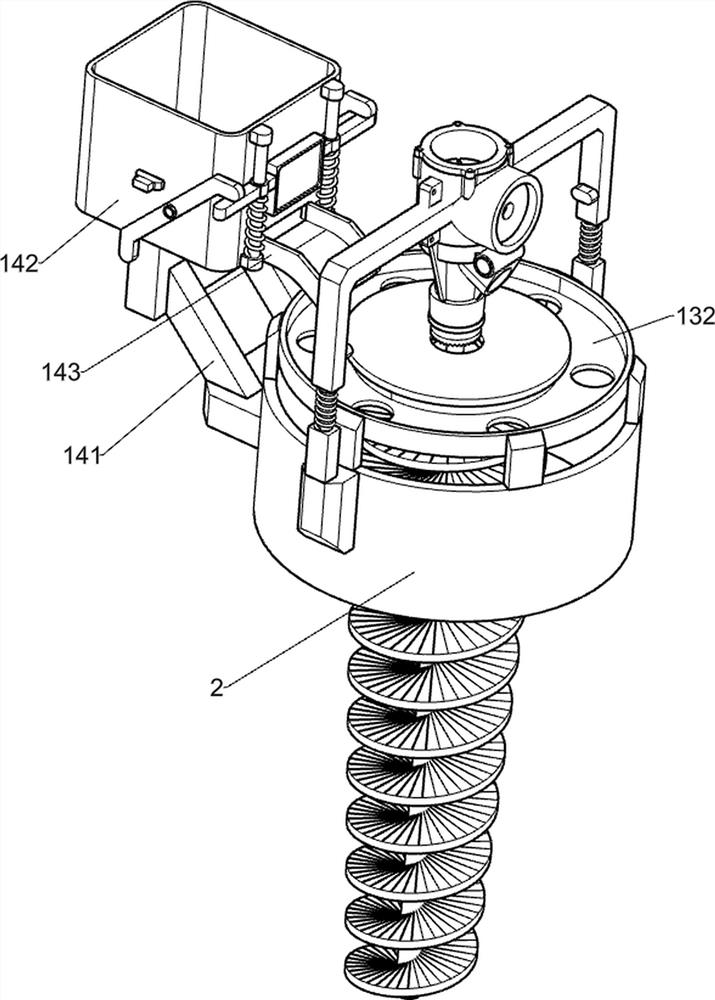

[0035] A shock-absorbing construction mortar mixing equipment, such as Figure 1-15 As shown, it includes support base 1, stirring box 2, observation window 3, discharge port 4, lifting platform 5, lifting frame 6, first spring 7, servo motor 8, stirring blade 9, anti-sticking mechanism 11 and storage mechanism 12. There is a mixing box 2 on the top of the support base 1, and an observation window 3 made of transparent glass is embedded in the middle of the mixing box 2. The bottom of the front side of the mixing box 2 is equipped with a discharge port 4 for mortar collection. Lifting platform 5 is provided on the front and rear sides, and the top of lifting platform 5 is slidingly provided with lifting frame 6. The first spring 7 is connected between lifting frame 6 and the top of lifting platform 5, and a servo is connected between the top of lifting frame 6. The motor 8 and the bottom of the output shaft of the servo motor 8 are provided with a stirring blade 9 for stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com