Grinding equipment with angle adjusting function

An angle adjustment and functional technology, applied in grinding/polishing equipment, grinding frame, grinding bed, etc., can solve problems such as complicated operation, high technical level requirements of operators, and high labor intensity of operators, and achieve Improve practicality, reduce labor intensity and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

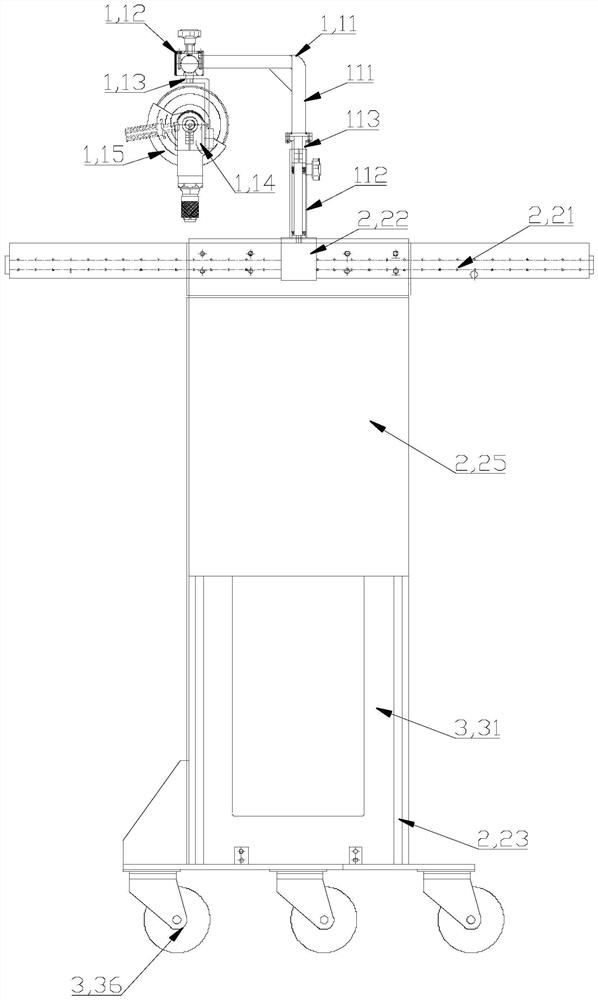

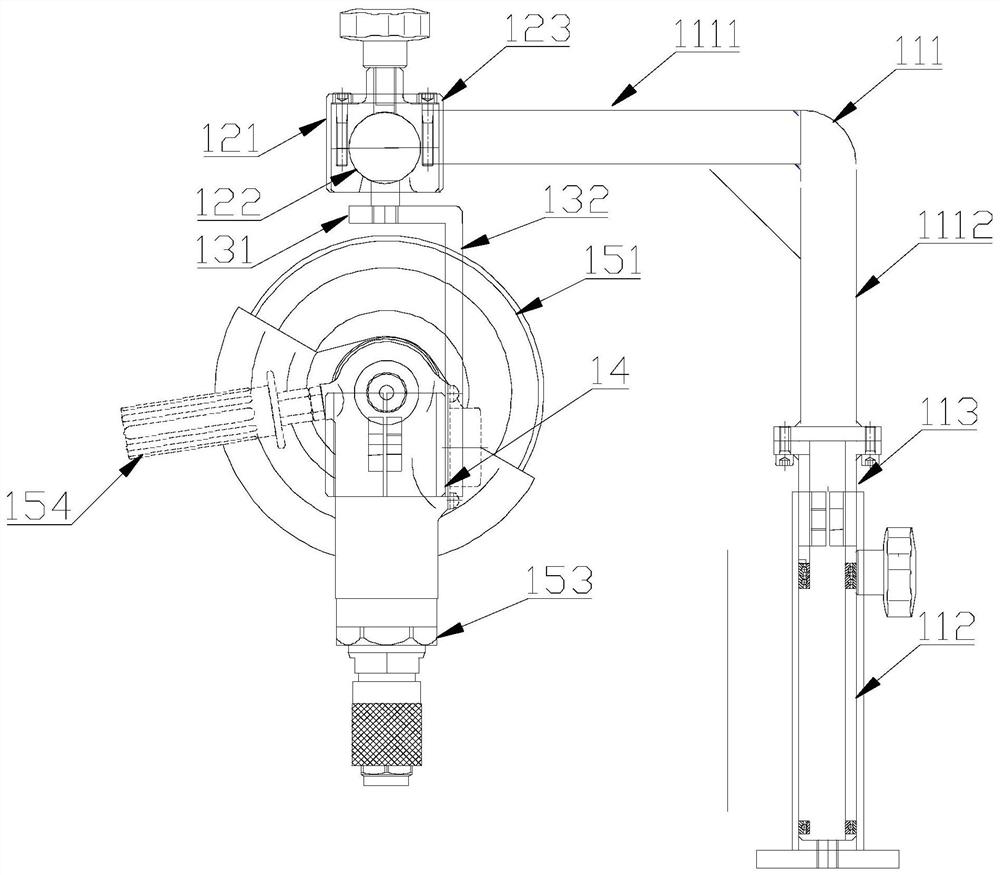

[0050] Such as Figure 1 to Figure 7 As shown, the embodiment of the present invention provides a grinding device with an angle adjustment function, including a drive system 2 and a grinding tool system 1, the grinding tool system 1 is fixed on the drive system 2, and the grinding tool system 1 includes The universal adjusting device and the grinding tool, one end of the universal adjusting device is fixedly connected with the drive system 2, and the other end of the universal adjusting device is rotatably connected with the grinding tool. The universal adjustment device is respectively connected with the drive system 2 and the abrasive tool, which not only realizes the adjustment of the angle of the abrasive tool according to the needs of the operator, but also realizes 360-degree grinding without dead ends, and can also adjust the abrasive tool under the drive of the drive system 2 In order to better meet the fine grinding operation requirements of different heights of rail ...

Embodiment 2

[0065] Such as figure 1 and image 3 As shown, the embodiment is a further limitation of the first embodiment above. In this embodiment, the drive system 2 is installed on the carrier system 3. The drive system 2 includes a horizontal moving device, and the horizontal moving device includes a support plate 25 extending in the vertical direction. The bottom of the support plate 25 is fixedly connected with the carrying system 3 , the support plate 25 is provided with a first slide rail 21 extending in the horizontal direction, and one end of the universal adjustment device is installed with a first slide block 22 correspondingly inserted into the first slide rail 21 . The horizontal moving device includes a first slide rail 21 and a first slide block 22, the universal adjustment device is fixedly connected with the first slide block 22, and the universal adjustment device moves horizontally along the first slide rail 21 through the first slide block 22, realizing The lateral f...

Embodiment 3

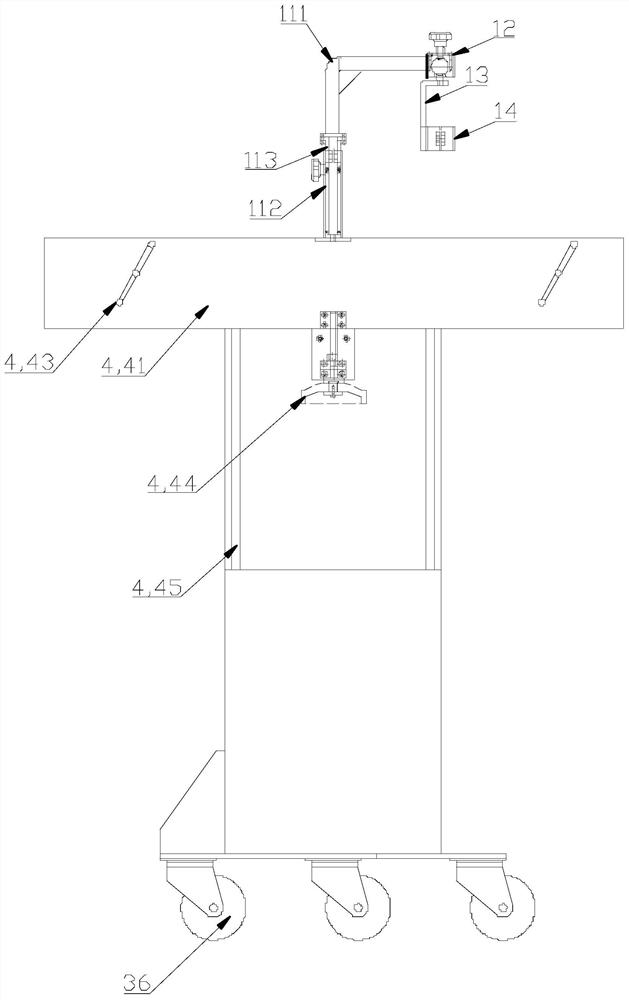

[0071] Such as Figure 1 to Figure 7 As shown, the embodiment is a further limitation of the second embodiment above. In this embodiment, it also includes a clamping mechanism for fixing the workpiece. The clamping system 4 is fixed on the carrier system 3. The clamping system 4 includes a front side plate 41 And rear side plate 42, front side plate 41 and rear side plate 42 are fixedly connected by tightening connecting rod 43, and tightening connecting rod 43 can adjust the gap between front side plate 41 and rear side plate 42, to realize according to the workpiece The width adjusts the gap between the front side panel 41 and the rear side panel 42 .

[0072] In this embodiment, a spring is provided between the front side plate 41 and the rear side plate 42, and the tightening link 43 passes through the front side plate 41, the spring and the rear side plate 42 in turn, so that the front side plate 41 and the rear side plate 42 is fixedly connected, and the gap between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com