Automatic welding device for vehicle thermal forming floor cross beam

An automatic welding and thermoforming technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of low work efficiency, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

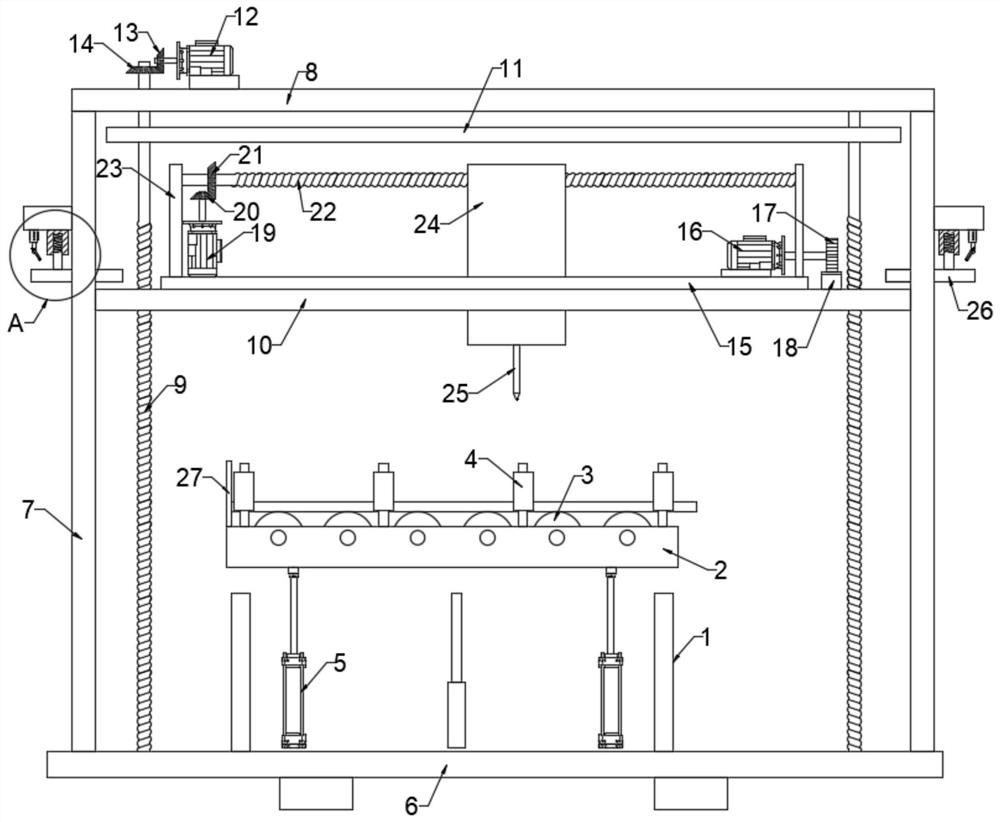

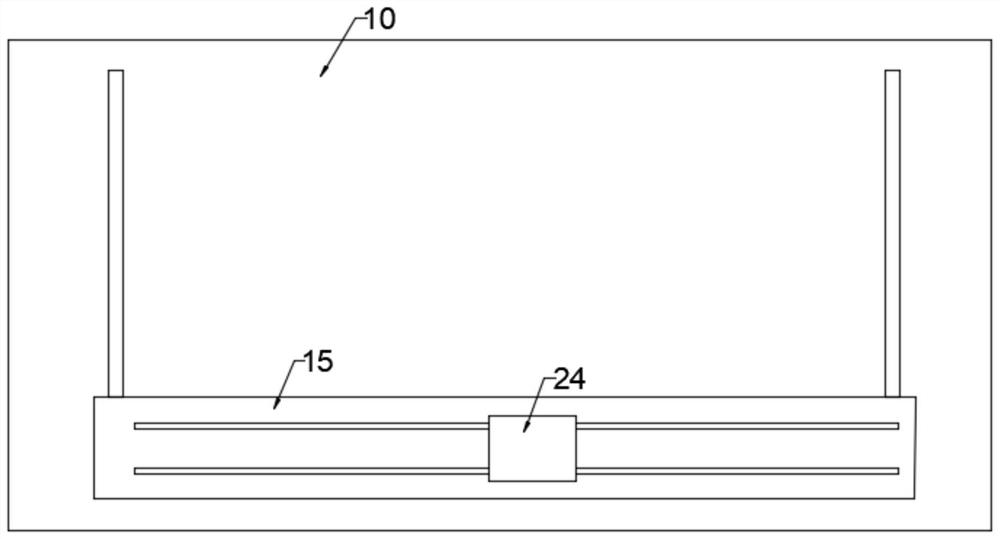

[0027] see Figure 1-5 , an automatic welding device for vehicle thermoformed floor beams, including a support base plate 6 and support plates 1 arranged on the support base plate 6 and symmetrically distributed, and an auxiliary moving mechanism for assisting floor movement is provided above the support plate 1, so A welding torch head 25 is arranged above the auxiliary moving mechanism. The welding torch head 25 is connected to a welding body 24 that controls its welding. The welding body 24 is connected to a space moving mechanism that drives it to move in three directions perpendicular to each other.

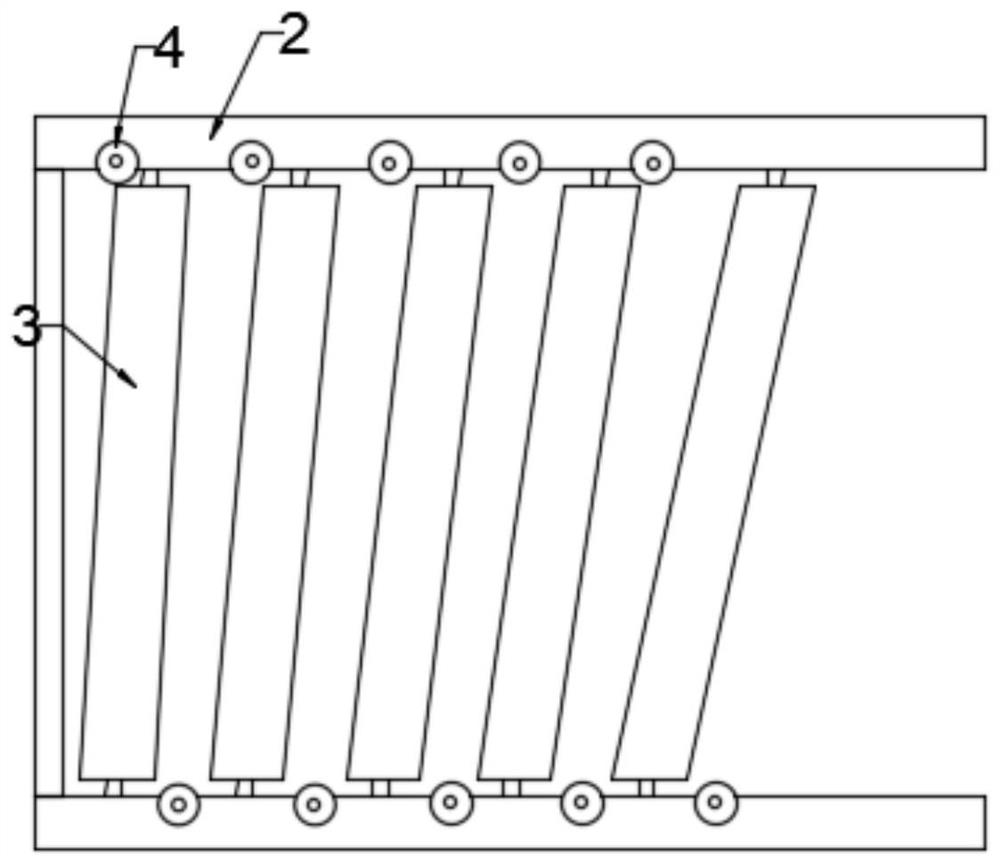

[0028] In this embodiment, the auxiliary moving mechanism includes two symmetrically arranged conveying platforms 2, and evenly distributed unpowered rollers 3 are connected between the two conveying platforms 2 through bearing rotation, and the two sides of the unpowered rollers 3 There are unpowered rollers 4 installed on the transmission platform 2, and the transmission p...

Embodiment 2

[0035] This embodiment has been expanded on the basis of Embodiment 1. A limiting plate 26 slidingly connected with each group of said poles 7 is provided. The limiting plate 26 is located above the lifting support plate 10, and the limiting plate 26 is fixed. Connected with a nesting rod 28, the nesting rod 28 is slidably connected with a fixed sleeve 29, the fixed sleeve 29 is provided with a chute 31 for matching, the chute 31 is elastically connected with the bottom of the nested rod 28 through an elastic member 32, and the fixed sleeve 29 is fixedly connected with a fixed seat 30 fixedly connected with the pole 7, and a travel switch 33 is installed on the fixed seat 30, and the travel switch 33 is electrically connected with the first driving motor 12, and the travel switch 33 is connected with a travel lever 34 that triggers its signal , the movable end of the stroke rod 34 faces the limit plate 26 and is lower than the lower end surface of the fixed sleeve 29. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com