Ultrasonic narrow gap welding system and method for aluminum alloys

A welding system and narrow gap technology, applied in the direction of welding equipment, welding accessories, welding rod characteristics, etc., can solve the problems that the welding speed cannot be further improved, weld pores defects, weld structure unevenness, etc., to avoid adverse effects, reduce Porosity, effect of improving process applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with specific embodiments.

[0052] The technical principle of the aluminum alloy ultrasonic narrow gap welding system and method with low thermal influence and high efficiency proposed by the present invention is as follows: the narrow gap arc welding method can be a swinging arc narrow gap, a swing arc narrow gap or a rotating arc narrow gap, using The swing or rotation of the arc preferentially ensures the fusion of the side walls. On this basis, the ultrasonic control method proposed by the present invention is used to improve the problems existing in the traditional narrow-gap arc welding of aluminum alloys. speed and improve the quality of aluminum alloy narrow gap arc welding.

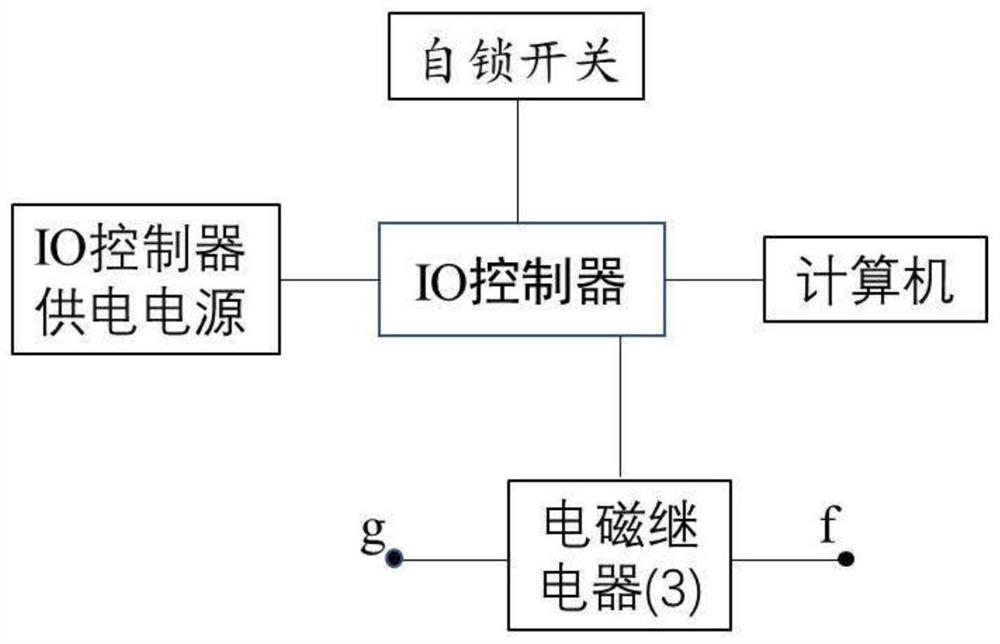

[0053] The ultrasonic excitation power supply is connected to the welding wire of the narrow gap welding torch and the workpiece to be welded through the coupled waveform control system, and the waveform of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com