Manufacturing process of photo-hydrogen ion catalyst net and photo-hydrogen ion air purification equipment

A technology of air purification equipment and manufacturing process, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, gas treatment, etc. It can solve the problems of potential safety hazards and single negative oxygen ion mode, and achieve Good trigger performance, long life, effect of reducing colds and epidemics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0029] The production of photohydrogen ion catalyst net needs to use titanium dioxide and carrier nickel foam. When titanium dioxide and carrier foam nickel are combined, at least one inorganic glue needs to be added to it. Will gradually lose the nature of glue, and will fall off.

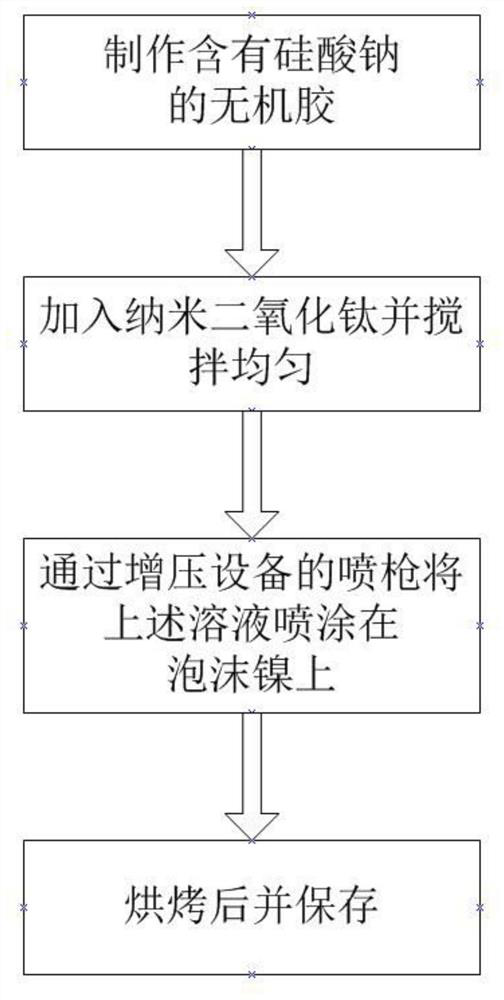

[0030] like figure 1 As shown, its production steps are as follows:

[0031] S1: Making inorganic glue containing sodium silicate: first, using sodium silicate and pure water to make inorganic glue according to the set ratio, the set ratio of sodium silicate is 20-60wt%;

[0032] S2: adding nano-titanium dioxide to the inorganic glue, the addition ratio of nano-titanium dioxide is 10-30wt%, stirring evenly to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com