A gap switch and method based on multi-point triggering of axial and radial laser beams

A gap switch, laser beam technology, applied in electronic switches, electrical components, pulse technology and other directions, can solve the problem of weakening, weakening, and affecting the laser triggering performance of the gap discharge channel, so as to improve the laser triggering performance and improve the triggering performance. , Improve the effect of gap trigger performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

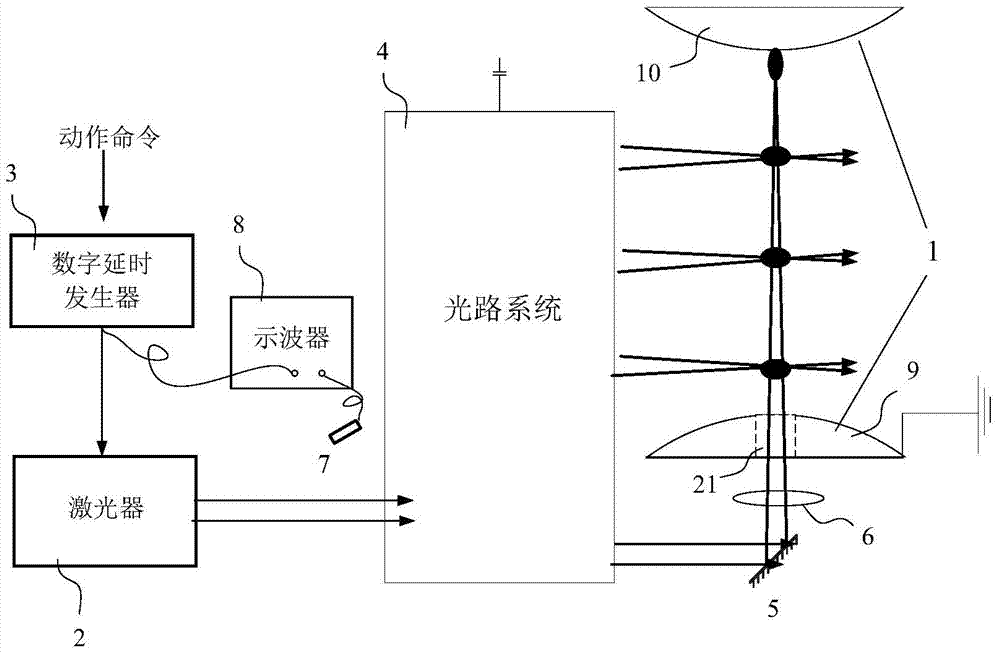

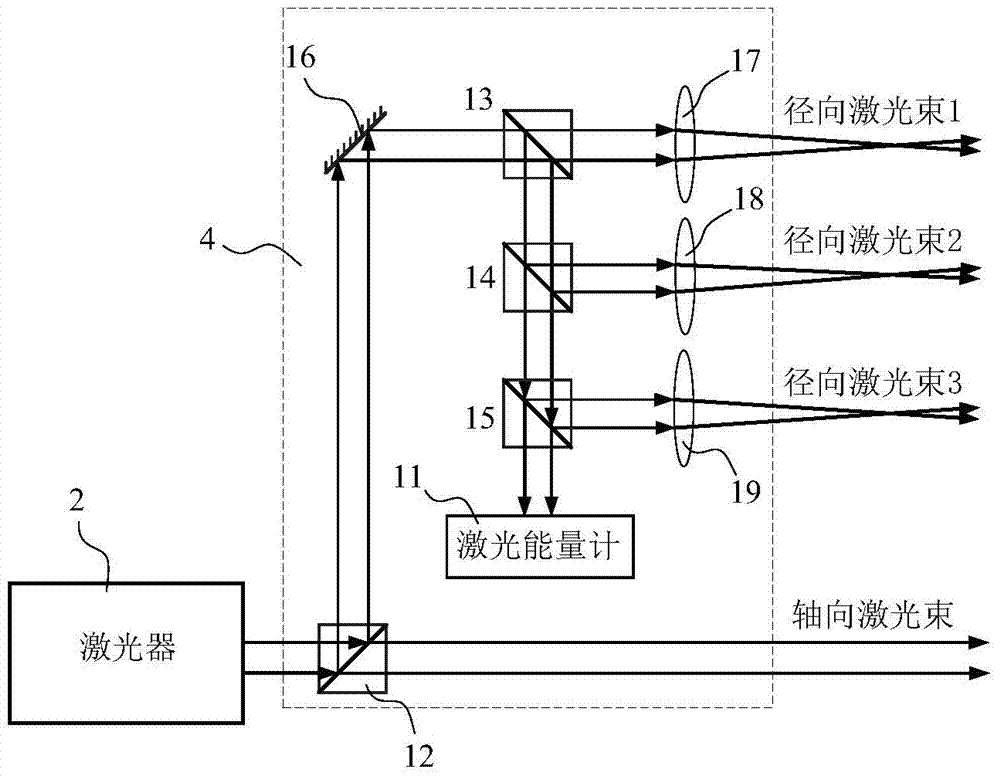

[0026] see figure 1 , the present invention is based on the gap switch triggered by multiple points of axial and radial laser beams, including a high-voltage DC air gap 1 composed of a ground electrode 9 and a high-voltage pole 10, used to establish an axial laser beam and at least one radial laser beam The optical path system 4 and the monitoring system for monitoring the state of the laser beam, the center of the ground electrode 9 is provided with a light-through hole 20 that allows the axial laser beam to pass through, and the diameter of the light-through hole 20 is 1 mm; the laser light generated by the laser 2 It enters from the incident end of the optical path system 4, and the two ends of the high-voltage DC air gap 1 are connected to the DC high voltage. The monitoring system includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com