Hydraulic control valve, hydraulic operating mechanism and circuit breaker using the hydraulic control valve

A technology of hydraulic control valve and hydraulic operation, applied in the fields of hydraulic control valve, hydraulic operation mechanism and circuit breaker, can solve the problems of easy oil leakage, complex structure of hydraulic control valve, complex structure of hydraulic operation mechanism, etc. Simple structure and the effect of reducing the difficulty of processing and assembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

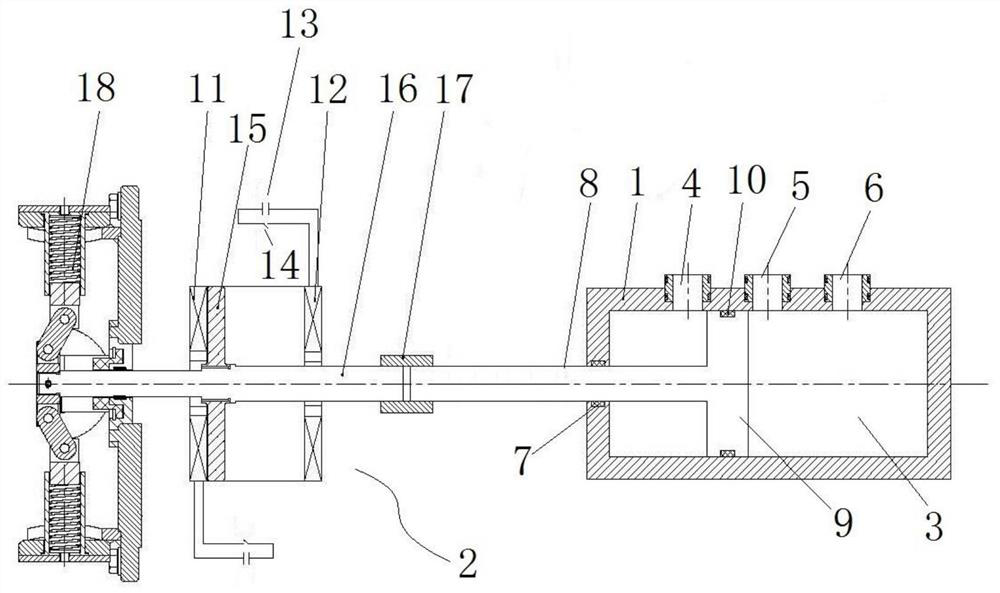

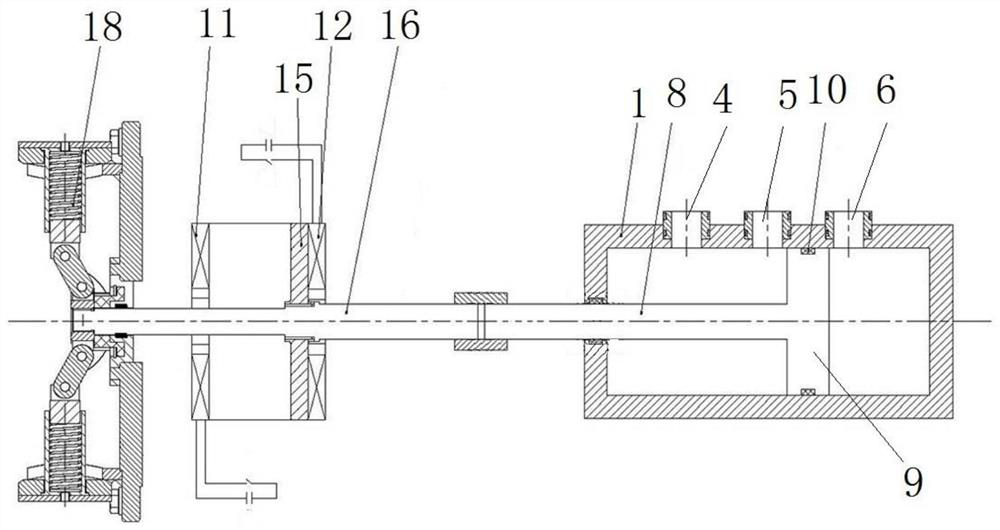

[0058] Such as Figure 1 to Figure 2 As shown, the hydraulic control valve includes a valve body 1, a valve core 9, a driving rod 8, and a repulsion mechanism 2 that drives the valve core 9 to reciprocate.

[0059] Such as figure 1 As shown, the longitudinal direction of the valve body 1 is the axial direction of the valve body 1 , the axial direction of the valve body 1 is the left-right direction, and the repulsion mechanism 2 is located on the left side of the valve body 1 . There is a valve cavity 3 inside the valve body 1, and the valve cavity 3 extends left and right, and the inner walls of the valve cavity 3 are all of equal diameter, so that the valve cavity 3 forms an equal diameter structure. The valve body 1 is provided with a normal high pressure oil port 4 , a control oil port 5 and a normal low pressure oil port 6 sequentially from left to right, and each oil port communicates with the inside of the valve cavity 3 . The normal and high pressure oil port 4, the ...

Embodiment 1

[0070] In Embodiment 1, the axial length of the spool is smaller than the axial distance between the normal high pressure oil port and the control oil port, and is also smaller than the axial distance between the normal low pressure oil port and the control oil port. In this embodiment, the axial length of the spool can be only smaller than the axial distance between the normal high pressure oil port and the control oil port, and equal to the axial distance between the normal low pressure oil port and the control oil port. Of course, it can also be slightly larger than the normal low pressure oil port. Axial distance between oil port and control oil port. Or the axial length of the spool can be only smaller than the axial distance between the normal low pressure oil port and the control oil port, and equal to the axial distance between the normal high pressure oil port and the control oil port. Of course, it can also be slightly larger than the normal high pressure oil port and...

specific Embodiment 3

[0072] In Embodiment 1, each oil port is radially arranged on the valve body. In this embodiment, the normal and low pressure oil ports can be arranged at the end of the valve body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com