Industrial robot battery clock method

An industrial robot and battery technology, applied in the direction of manipulators, manufacturing tools, etc., can solve problems affecting the production and processing of objects, potential safety hazards, loss of positions, etc., to avoid motor operation errors and ensure the effect of operation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

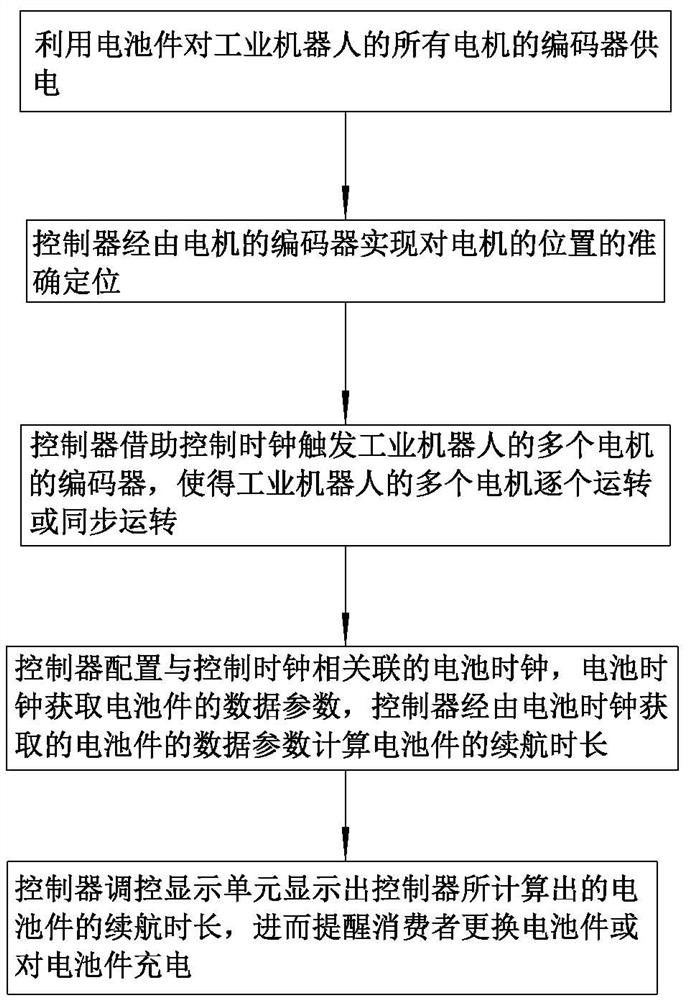

[0022] see figure 1 Shown, a kind of industrial robot battery clock method of the present invention comprises the steps:

[0023] Configure batteries, which are used to supply power to the encoders of multiple motors of industrial robots;

[0024] Equipped with a controller, the controller is electrically connected to the encoder of the motor, and the controller realizes the precise positioning of the position of the motor through the encoder of the motor; according to actual needs, the battery can be installed in the base of the industrial robot, or can be installed In the chassis of the control box, the protection of the battery is realized to prevent the battery from being damag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com