Chamfering equipment for inner circles on two sides and implementation method thereof

A technology of chamfering and equipment, applied in the field of chamfering, can solve the problems of high labor intensity, difficulty in ensuring product production efficiency, and difficult control of chamfering consistency, and achieve the effect of reducing labor intensity, continuous processing, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

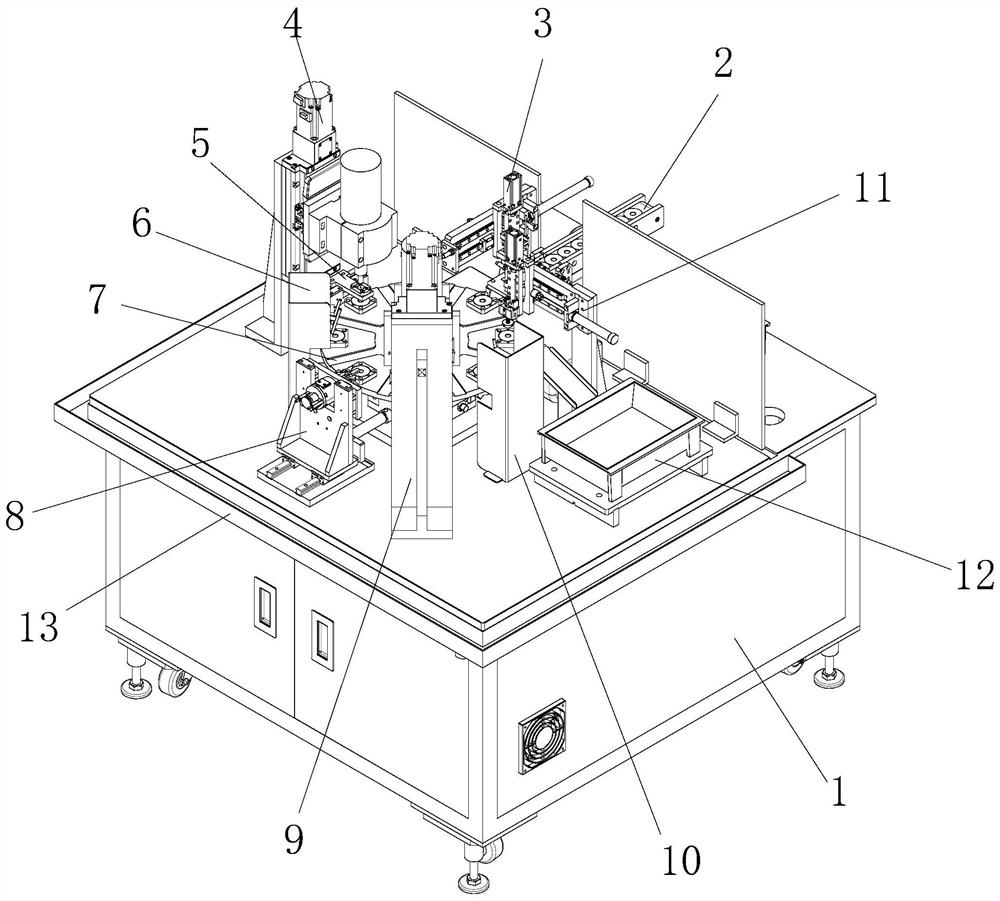

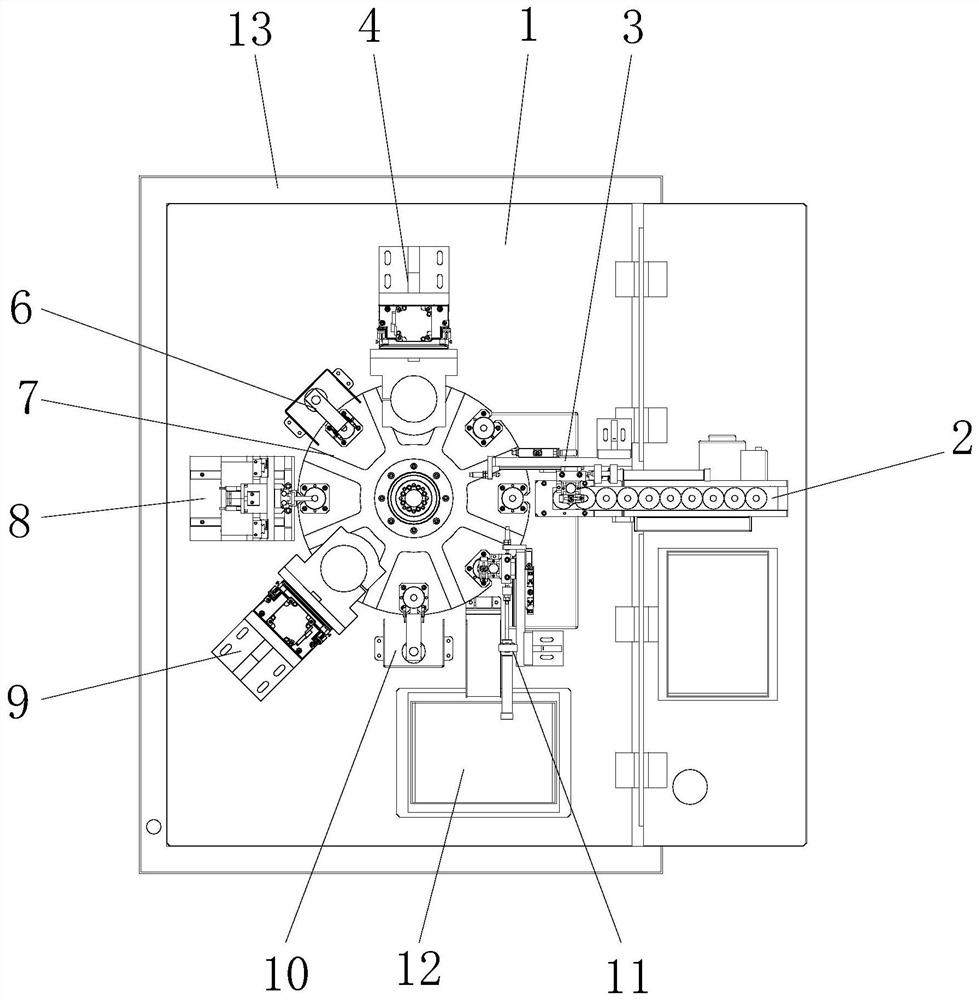

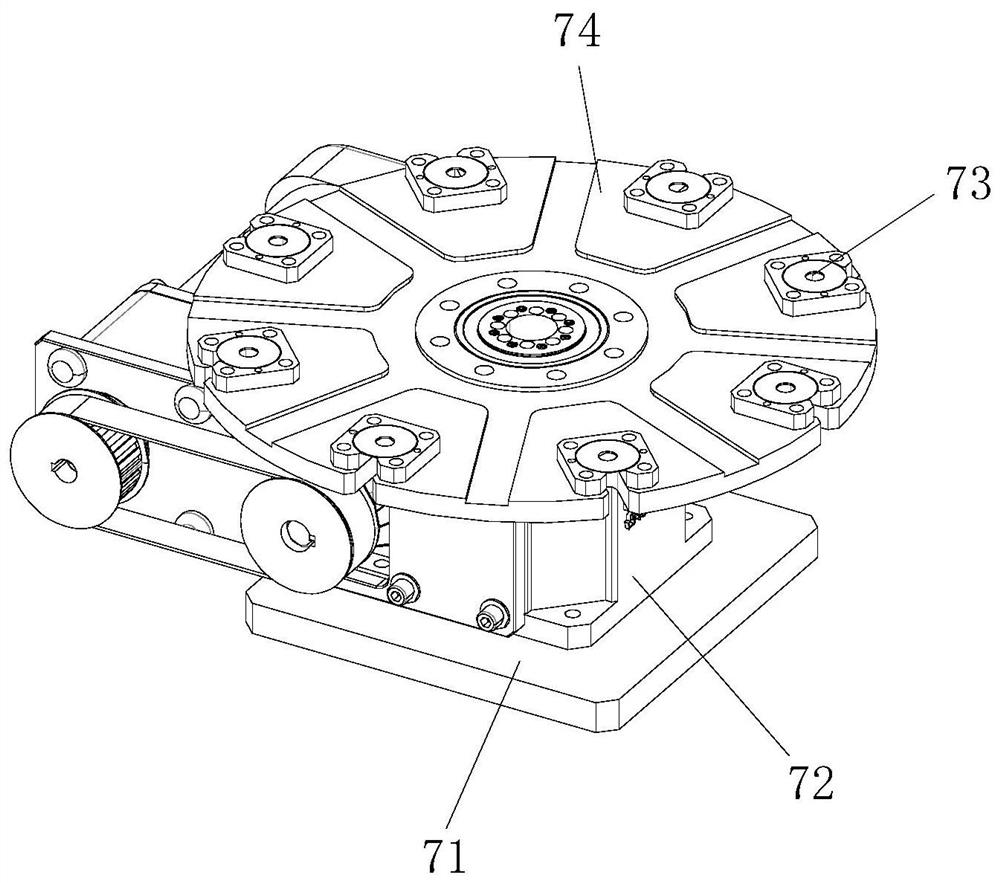

[0051] see Figure 1-9 , the present invention provides the following technical solutions: a double-sided inner circle chamfering equipment, including a frame 1, the middle position above the frame 1 is provided with a rotating platform mechanism 7, and the frame 1 is sequentially provided with a rotating platform mechanism 7 The corresponding suction feeding mechanism 3, the first lifting and chamfering mechanism 4, the first carrier cleaning mechanism 6, the automatic turning mechanism 8, the second lifting and chamfering mechanism 9, the second carrier cleaning mechanism 10 and the suction and unloading mechanism 11, and the top of the frame 1 is provided with a feeding conveyor belt mechanism 2 located below the suction and feeding mechanism 3, and the top of the frame 1 is also provided with a material receiving rubber frame 12 below the suction and unloading mechanism 11, and the feeding and conveying Belt mechanism 2, suction feeding mechanism 3, first lifting and chamf...

Embodiment 2

[0065] The difference between this embodiment and Embodiment 1 is that specifically, the first carrier cleaning mechanism 6 includes a mounting bracket 61, a water shield 62, an air nozzle mounting seat 63 and an air nozzle 64, wherein the mounting bracket 61 is installed on the frame 1, the upper end of the mounting bracket 61 is connected with the air nozzle mounting seat 63, the air nozzle mounting seat 63 is connected with the air nozzle 64, and the outside of the mounting bracket 61 is provided with a water retaining cover 62, and the water retaining cover 62 is installed on the frame 1, a water tank 13 is connected around the frame 1, and the structure of the second carrier cleaning mechanism 10 is the same as that of the first carrier cleaning mechanism 6.

[0066] By adopting the above technical solution, the tool carrier 73 is cleaned by blowing air through the air nozzle 64, the water shield 62 is used to block the blown water mist, and the water tank 13 collects the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com