Smoke constant-temperature equipment for areca nut processing

A technology of constant temperature equipment and betel nut, applied in lighting and heating equipment, application, heating element shape and other directions, can solve the problem of uncontrollable flue gas temperature, and achieve the effect of reducing energy consumption, protecting the surrounding environment, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

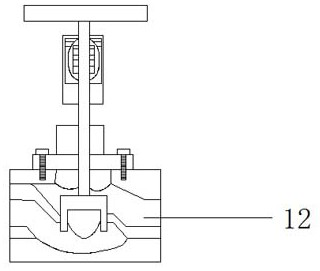

[0019] Embodiment 1, with reference to Figure 1-3 , a kind of smoke constant temperature equipment for betel nut processing, comprising a box body 1, a combustion box 2 is welded on the outer wall of the bottom side of the box body 1, and a smoke inlet pipe 3 is welded on the outer wall of the top of the combustion box 2, and a smoke inlet pipe 3 is welded on the side wall of the combustion box 2 There is an inspection door on the outer wall, and the outer wall on one side of the inspection door is fixed with a handle by bolts. The outer wall on one side of the smoke inlet pipe 3 is welded with a heating box 4, and the heating box 4 is equipped with electric heating wires 5 distributed equidistantly. The electric heating wire 5 installed inside the heating box 4 can heat the inside of the box body 1 to maintain the internal temperature. At the same time, the rotation of the servo motor 8 can make the betel nuts inside the hollow barrel 10 more evenly smoked, which can improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com