Fabricated ecological retaining wall and safety checking calculation method thereof

An ecological retaining wall and prefabricated technology, applied in excavation, foundation structure test, water conservancy engineering, etc., can solve problems such as design structure or complex construction method, poor environmental coordination performance of reinforced concrete structures, and large engineering volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

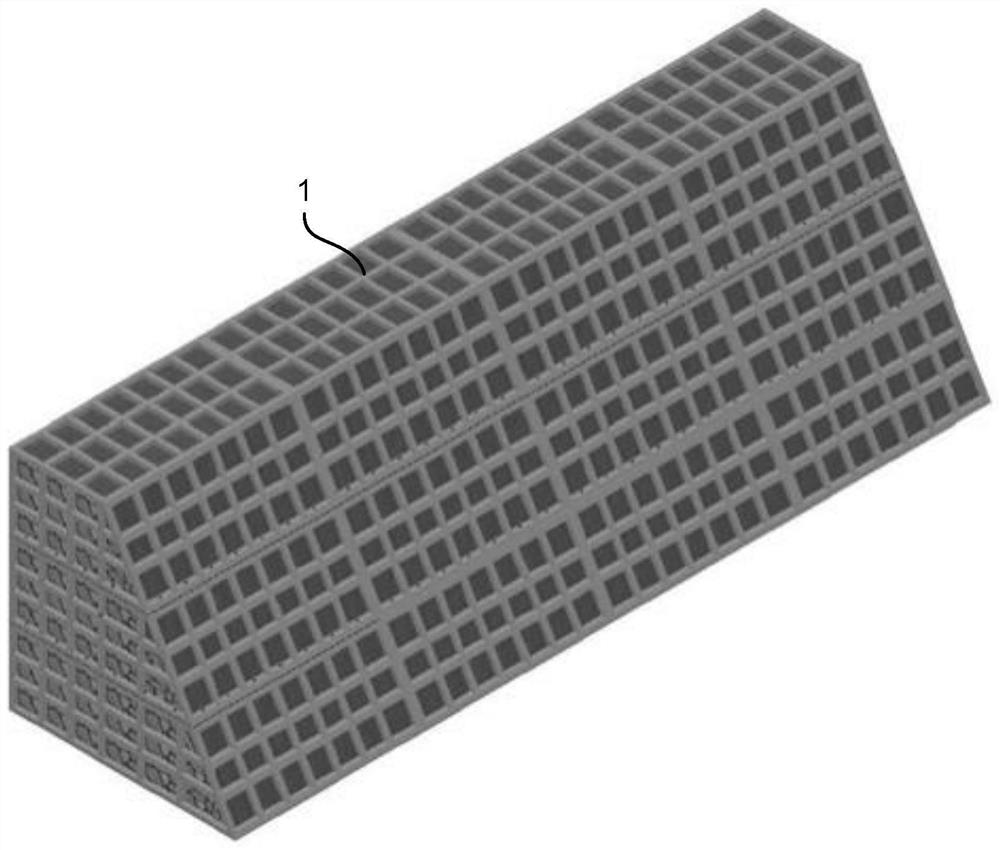

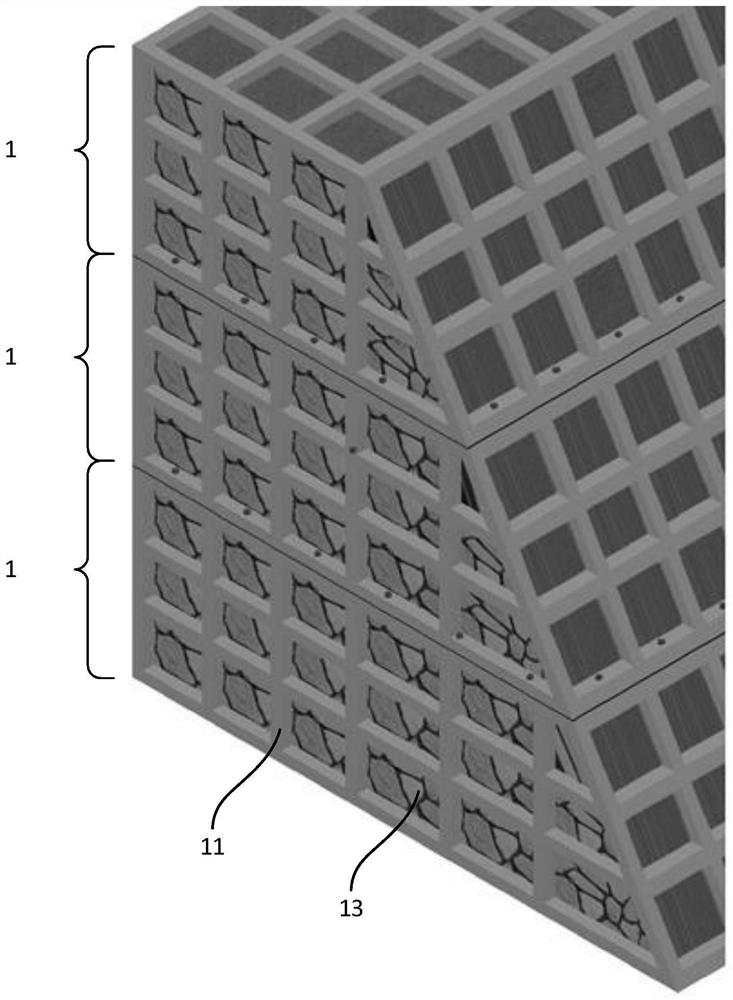

[0119] Such as Figure 1 to Figure 4 Shown, design a kind of prefabricated ecological retaining wall of the present invention.

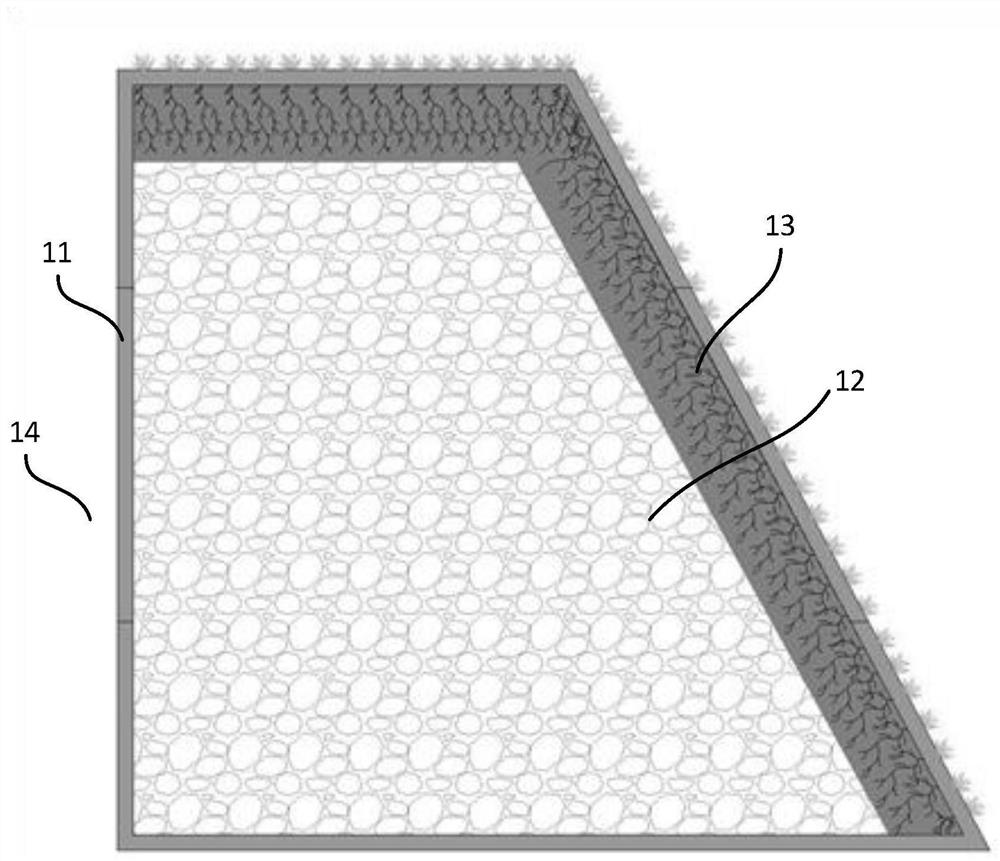

[0120] figure 1 It is a schematic diagram of the overall structure of the prefabricated ecological retaining wall, figure 2 yes figure 1 A partial enlargement of the . The prefabricated ecological retaining wall is a strip-shaped trapezoidal platform structure in which multiple layers of monomers 1 are overlapped and assembled into one. The monomers 1 are fixedly connected; the main body of the monomer 1 is a trapezoidal platform-shaped steel frame 11, and the steel frame 11 is filled with two layers of matrix. The inner layer is a counterweight matrix layer 12, and the outer layer is an ecological matrix layer 13.

[0121] The steel frame 11 adopts a cross grid steel frame. Steel frame 11 steel bars adopt round steel, H-shaped steel, angle steel, channel steel all can. In order to save material cost, there is no ecological matrix layer 13 on ...

Embodiment 2

[0125] Such as Figure 4 As shown, combined with the site conditions, the safety check calculation of the prefabricated ecological retaining wall designed in Example 1 is carried out.

[0126] 1. Wall anti-slip stability checking calculation

[0127] Step S11, on-site investigation to determine the basic parameters

[0128] The basic parameters include the basic parameters of the slope body and the structural design parameters of the prefabricated ecological retaining wall. The structural design parameters of the prefabricated ecological retaining wall are shown in Example 1. The basic parameters of the slope include the statistical average values of various soil parameters x multiple investigation and measurement results u x with standard deviation σ x ,As shown in Table 1. Figure 4 It is a schematic diagram of the meaning of the basic parameters of some slopes and a force analysis diagram of the retaining wall.

[0129] Table 1 Basic parameters of the slope

[013...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com