Fabricated revetment

A prefabricated and prefabricated assembly technology, applied in piers, quay walls, embankments, etc., can solve the problems of single waterproof measures, corrosion damage to bank protection, weak waterproof performance, etc., to achieve the effect of flood prevention and water blocking, cost saving, and overall stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

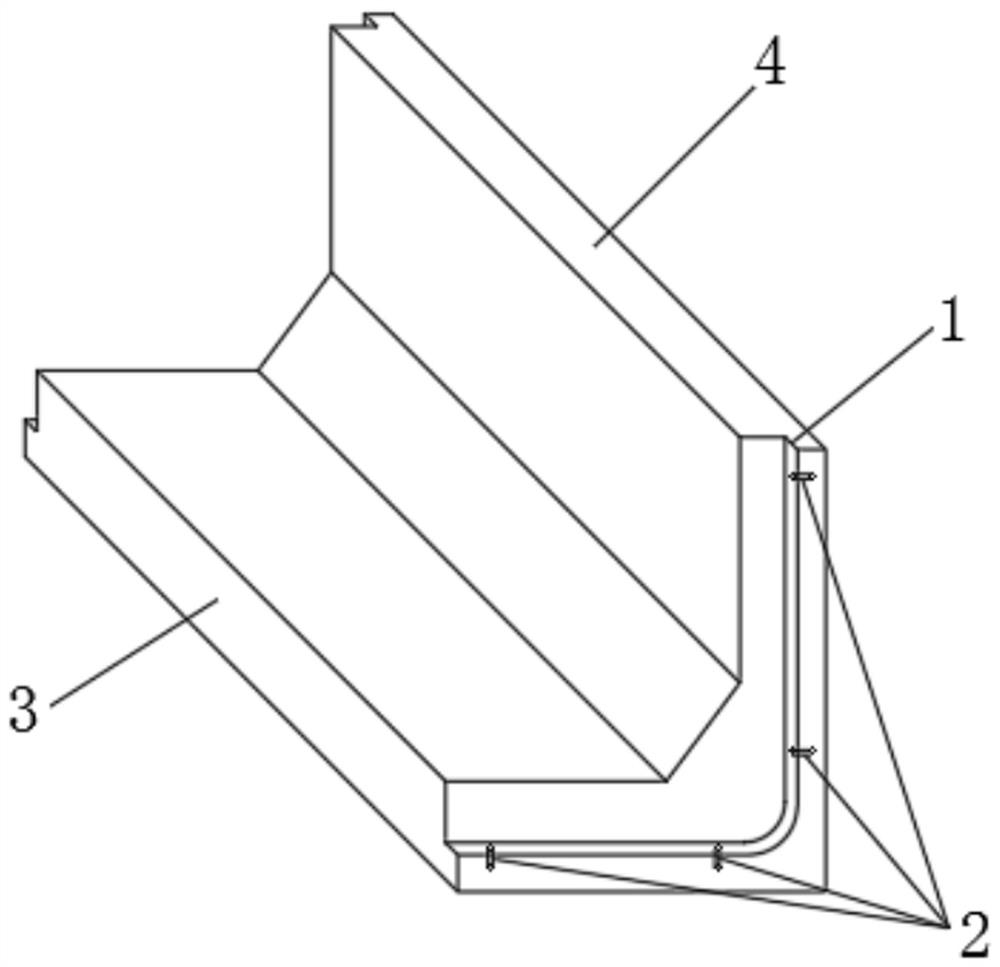

[0020] The engineering revetment is composed of L-shaped concrete prefabricated revetment sections, and the elevation of the concrete prefabricated revetment section is as follows figure 1 As shown, it includes an extension section 1 and a bolt hole 2 is reserved. Two adjacent L-shaped prefabricated revetment sections are connected by splicing extensions, and a spliced groove is formed on the inner side of the extension. The two ends are respectively connected by bolts to the corresponding reserved bolt holes of the two adjacent L-shaped prefabricated revetment sections, and the expansion mortar is poured into the groove and the assembly gap between the two adjacent L-shaped prefabricated revetment sections. The surface adopts one-component polyurethane sealant to form a sealing ring. Each piece of the L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com