Method for conditioning sludge by two-phase folded plate flow bio-leaching reactor

A technology of bioleaching and reactor, which is applied in the direction of biological sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of lower bioleaching efficiency, high operating cost, and long bioleaching cycle, etc., to achieve Shorten the bioleaching cycle, improve dehydration performance, and weaken the effect of inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The sludge used in this embodiment is taken from Shangyao Sewage Treatment Plant in Guilin City, and its specific steps are as follows:

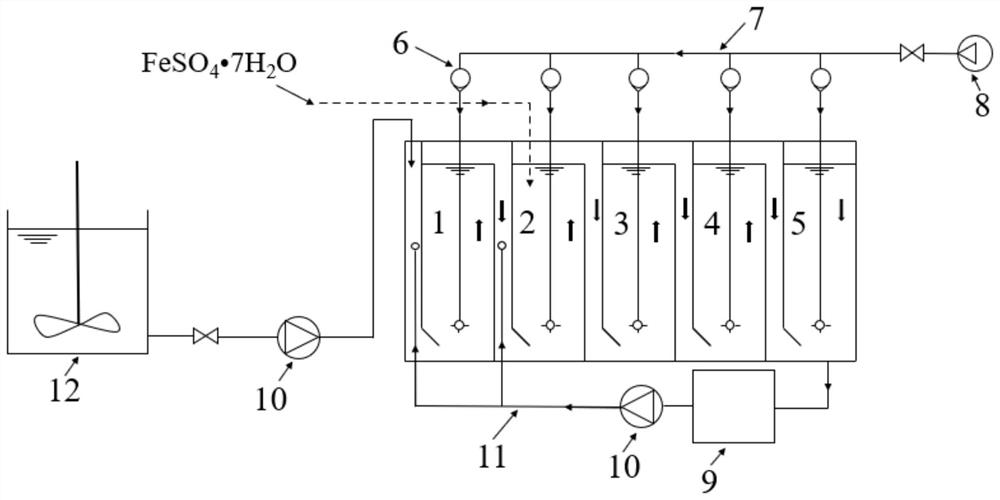

[0023] (1) Reactor setup: The reactor includes a reaction chamber, an aeration device, a sludge return device, FeSO 4 ·7H 2 O dosing device, mixing tank 12 and mud storage device. The reaction chamber includes a first compartment 1, a second compartment 2, a third compartment 3 and a fourth compartment 4, the aeration device includes a gas meter 6, an air pump 7 and an aeration pipe 8, and the sludge return device includes a peristaltic pump 10 and a sludge return pipe 11, the sludge storage device includes a sludge storage chamber 5 and a sludge storage tank 9. The reaction chamber is divided into two parts, the first part includes the first compartment 1, the second part includes the second compartment 2, the third compartment 3 and the fourth compartment 4, and the ratio of the first part to the second part is 1:3.

[0024] (3) ...

Embodiment 2

[0030] The sludge used in this embodiment is taken from Shangyao Sewage Treatment Plant in Guilin City, and the specific operation process is as follows:

[0031] (1) Reactor setup: The reactor includes a reaction chamber, an aeration device, a sludge return device, FeSO 4 ·7H 2 O dosing device, mixing tank 12 and mud storage device. The reaction chamber includes a first compartment 1, a second compartment 2, a third compartment 3 and a fourth compartment 4, the aeration device includes a gas meter 6, an air pump 7 and an aeration pipe 8, and the sludge return device includes a peristaltic pump 10 and a sludge return pipe 11, the sludge storage device includes a sludge storage chamber 5 and a sludge storage tank 9. The reaction chamber is divided into two parts, the first part includes the first compartment 1, the second part includes the second compartment 2, the third compartment 3 and the fourth compartment 4, and the ratio of the first part to the second part is 1:3.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com