Automobile charging pile

A technology of car charging and charging piles, which is applied in the direction of electric vehicle charging technology, charging stations, electric vehicles, etc., and can solve the inconvenient use of car charging piles, the inability to monitor the environment of car charging piles, and the inability to move, retrieve and store car charging piles, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

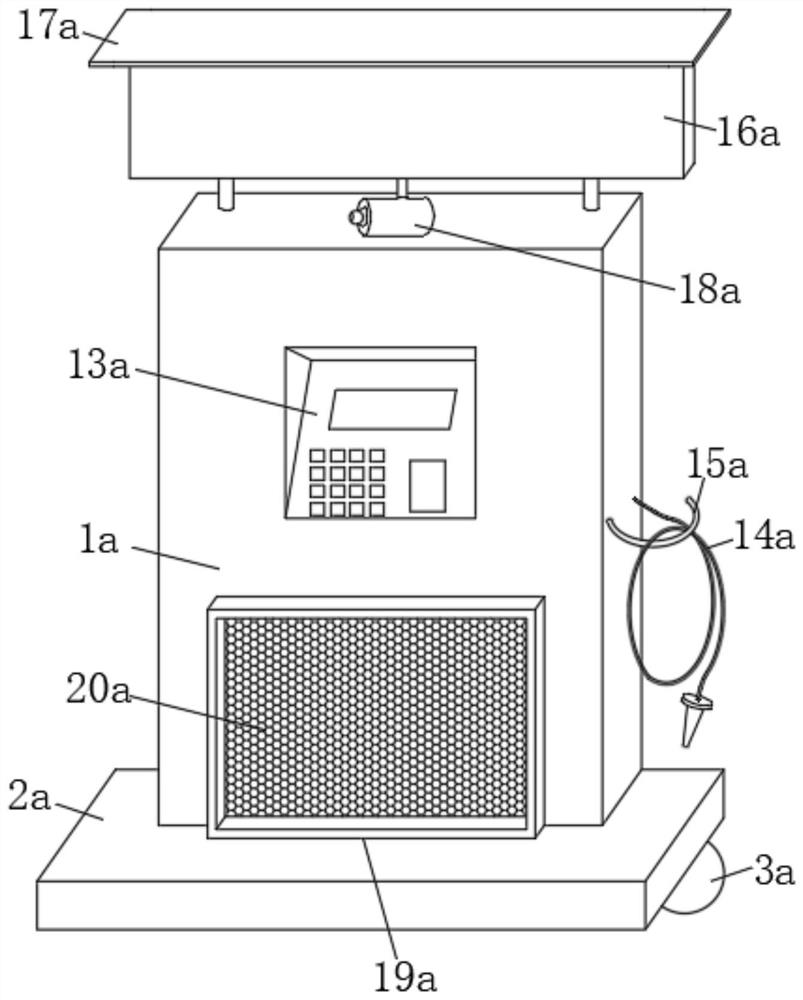

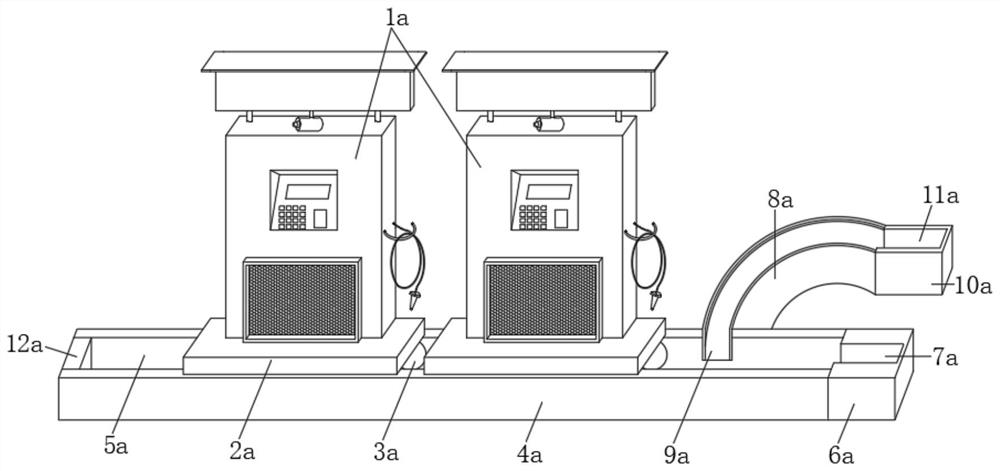

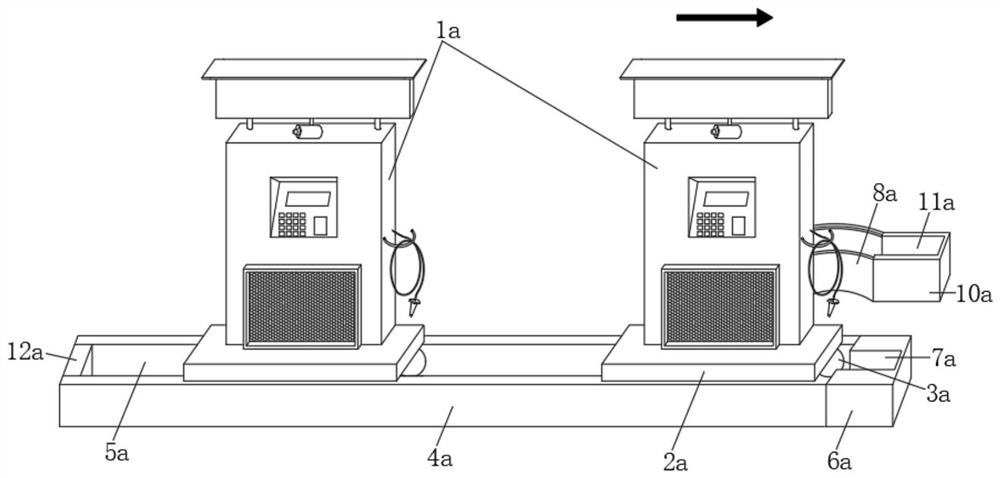

[0043]SeeFigure 1-7 This embodiment provides a technical solution: an automobile charging pile, including a charging pile body 1a and a linear slide 4a, the top of the charging pile body 1a is fixedly connected with a moisture-proof seat 2a, and the bottom of the moisture-proof seat 2a is fixedly installed with a rail The number of wheels 3a and rail wheels 3a is two. The two rail wheels 3a are symmetrically arranged at the bottom of the moisture-proof seat 2a. The top of the linear slide 4a is provided with a linear groove 5a, and the rail wheel 3a is movably connected in the linear groove 5a, One side of the linear slide rail 4a is fixedly connected with a first positioning seat 6a, and a side of the first positioning seat 6a close to the linear slide rail 4a is provided with a first fitting groove 7a, and the first fitting groove 7a is in communication with the linear groove 5a , The right end of the rear side of the linear slide rail 4a is fixedly connected with an arc rail 8a, ...

Embodiment 2

[0053]On the basis of the first embodiment above, this embodiment also provides an automobile charging pile with a lighting system;

[0054]CombineFigure 1 to Figure 19As shown, the car charging pile includes a charging pile body 1a, a linear slide 4a and a lamp post 1. The top of the charging pile body 1a is fixedly connected with a moisture-proof seat 2a, and the bottom of the moisture-proof seat 2a is fixedly installed with a rail wheel 3a. The number of 3a is two. The two rail wheels 3a are symmetrically arranged at the bottom of the moisture-proof seat 2a. The top of the linear slide rail 4a is provided with a linear groove 5a, and the rail wheel 3a is movably connected in the linear groove 5a. One side is fixedly connected with a first positioning seat 6a, and a first fitting groove 7a is formed on the side of the first positioning seat 6a close to the linear slide rail 4a. The first fitting groove 7a communicates with the linear groove 5a, and the linear slide rail 4a The right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com