Method for Improving Idling Vibration Isolation Performance of Front Mount of Family Car Engine

An engine and front mount technology, applied in power units, mechanical equipment, vehicle components, etc., can solve the problems of not paying attention to infrasound detection, and cannot exclude the vibration isolation performance of mounts, and achieve the effect of improving comfort and reducing anxiety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

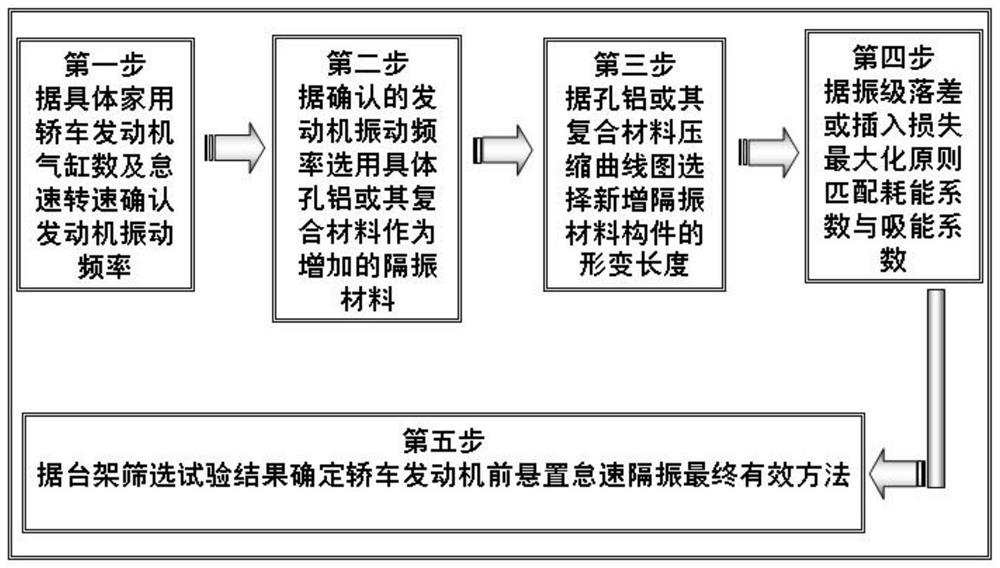

[0050] Embodiment 1: a kind of method that promotes family car engine front mount idling vibration isolation performance, such as figure 1 as shown,

[0051] Step 1: Confirm the engine vibration frequency (rhythmofengine) according to the number of cylinders and idle speed of the specific family car engine:

[0052] The engine selected by the present invention is four cylinders and its displacement is the family car engine of 1.8L. The reason for selecting this engine is that it has more market share; its idle speed range is from 600 rpm to 800 rpm. Or if it is 10 rpm to 13.33 rpm, the engine vibration frequency is 20Hz to 26.66Hz. The basis for confirming the vibration frequency is:

[0053] For a four-cylinder engine, the crankshaft rotates 2 times in each working cycle of the engine, and the 4 cylinders are ignited and exploded in the order of 1342 in each working cycle; that is to say, the engine explodes twice per revolution, or vibrates twice. Therefore, for a 4-cylin...

Embodiment 2

[0080] The selected hole aluminum-perlite composite material, engine, front suspension, and test bench are all the same as in Example 1 with the test equipment, and the operation steps and test methods are also the same as in Example 1, and different from Example 1. yes:

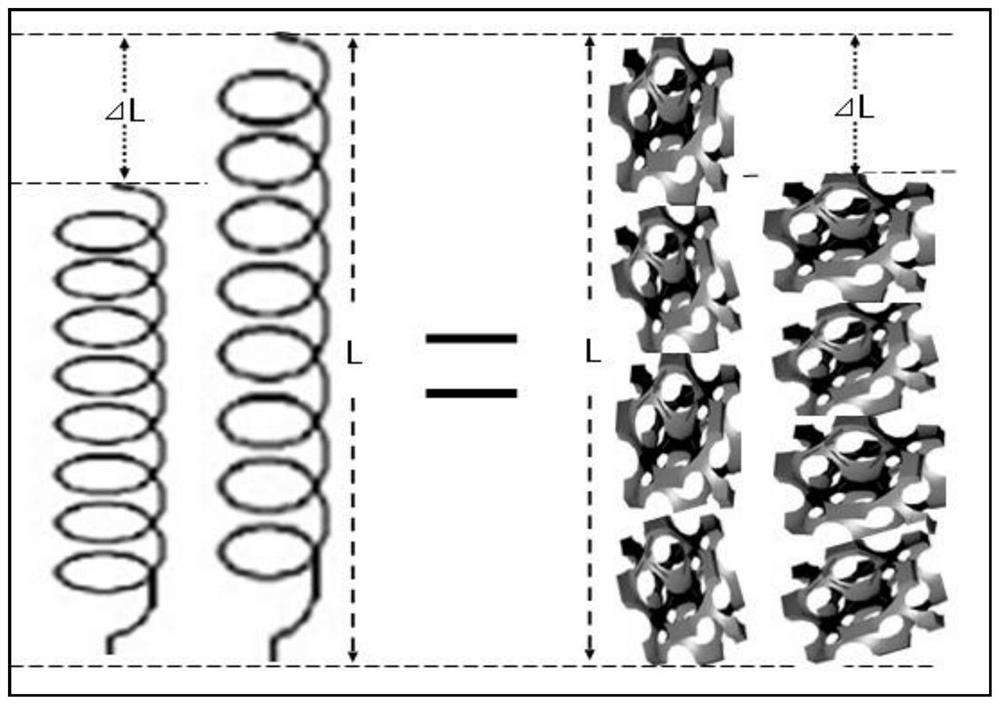

[0081] The compression deformation length ⊿L of the porous aluminum-perlite composite member is designed and processed to be 10%, or ⊿L=10%; the vibration level difference after the ⊿L=10% member is 8.9551, and the improved rear isolation The vibration effect has been increased by 60.94%.

Embodiment 3

[0083] The selected hole aluminum-perlite composite material, engine, front suspension, and test bench are all the same as in Example 1 with the test equipment, and the operation steps and test methods are also the same as in Example 1, and different from Example 1. yes:

[0084] The compression deformation length ⊿L of the porous aluminum-perlite composite member is designed and processed to be 5%, or ⊿L=5%; the vibration level difference after the member with ⊿L=10% is 6.732, and the improved rear isolation The vibration effect has been increased by 20.98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com