Rapid steel residue cleaning device for sheet metal laser cutting machine

A laser cutting machine and cleaning device technology, applied in laser welding equipment, welding/welding/cutting items, metal processing equipment, etc., can solve the problems of reduced cleaning efficiency, hazards to surrounding staff, and reduced work efficiency, etc., to achieve convenience The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

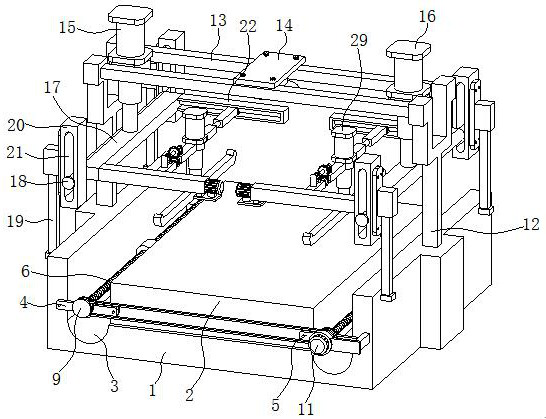

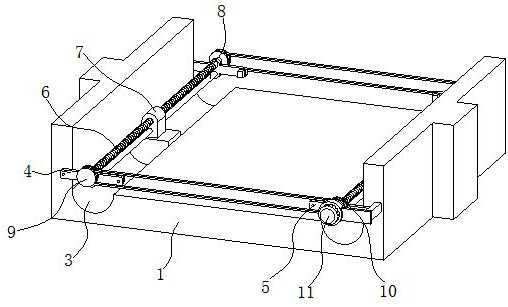

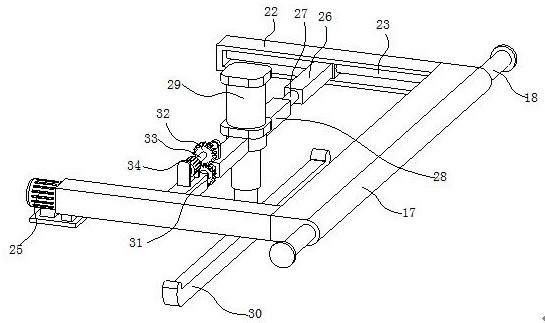

[0027] like Figure 1-5 As shown, the present invention provides a technical solution: a rapid steel residue cleaning device for a sheet metal laser cutting machine, comprising a base 1, a cutting table 2 and a beam 13, the bottom of the cutting table 2 is fixedly connected to the base 1, and the base Both ends of the base 1 are provided with residue collection tanks 3, one end of the front and back of the base 1 is fixedly installed with a first connecting frame 4, and one end of the front and back of the base 1 away from the first connecting frame 4 is fixedly installed with a second connecting frame 4. Frame 5, the opposite sides of two first connecting frames 4 and two second connecting frames 5 are all sleeved with conveying screw 6, and the outside of conveying screw 6 is socketed with cleaning plate 7, two first connecting frames 4 and two The opposite sides of the second connecting frame 5 are all fixedly installed with first limit rods 8, and both sides of one of the ...

Embodiment 2

[0030] like Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the cleaning plate 7 is sleeved on the outside of the first limit rod 8, the cleaning plate 7 is located inside the residue collection tank 3, and the cleaning plate 7 and the residue The inner walls of the collecting tank 3 are attached together.

[0031] In this embodiment, by socketing the cleaning plate 7 on the outside of the first limiting rod 8, the first limiting rod 8 will limit the cleaning plate 7, so that the cleaning plate 7 can move normally. Since the cleaning plate 7 and the inner wall of the residue collection tank 3 fit together, the cleaning plate 7 can effectively clean the residue attached to the inner wall of the residue collection tank 3 , thereby facilitating the use of the residue collection tank 3 .

Embodiment 3

[0033] like Figure 1-5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: there are two crossbeams 13, and both sides of the crossbeam 13 are fixedly equipped with mounting frames 12, and the bottom of the mounting frame 12 is connected to the base 1 fixed connection.

[0034] In this embodiment, the crossbeam 13 is supported by setting the mounting frame 12 , and the crossbeam 13 is connected to the base 1 through the mounting frame 12 , which is beneficial to the stable support of the crossbeam 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com