Toast box cover spray coating jig

A technology of cover and toast, applied in the direction of spraying device, etc., can solve the problems of non-stick surface losing use effect, poor positioning of cover structure, adding more solid waste, etc., to achieve non-stick effect and good performance, avoid bad products, The effect of reducing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

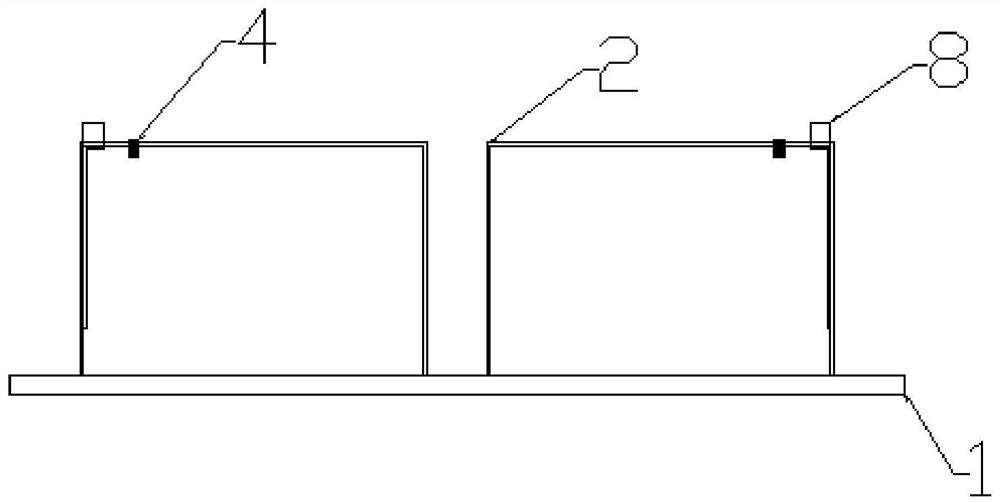

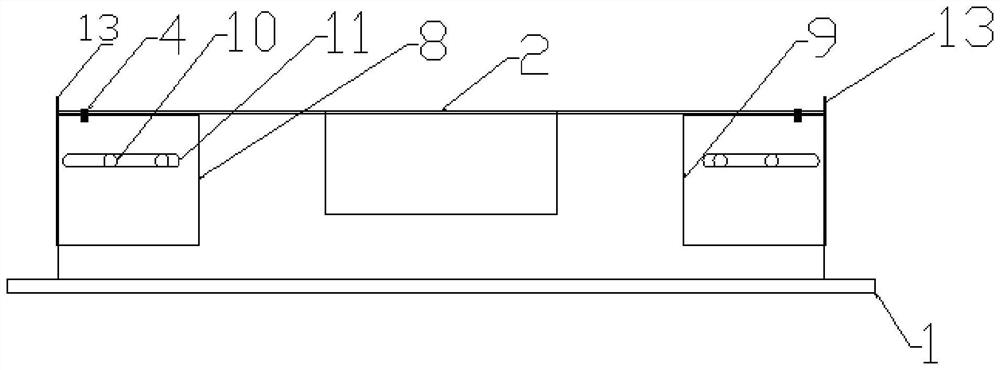

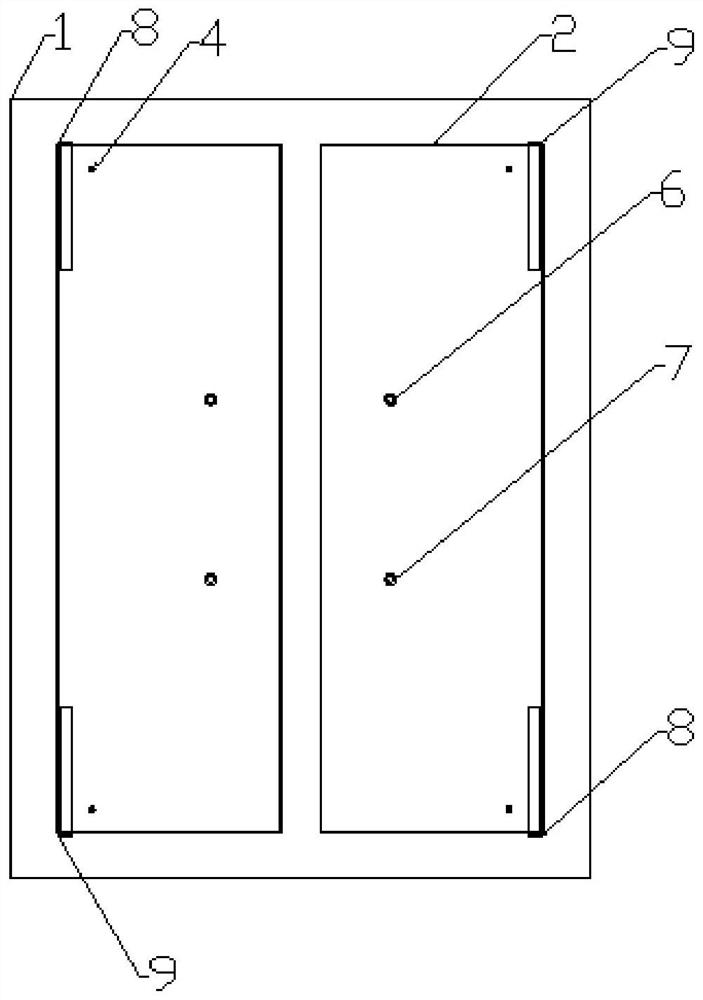

[0026] Such as Figure 1-8 As shown, this embodiment provides a toast box lid spraying jig, including a first base 1, a first limiting plate 8 and the second limiting plate 9, wherein: the first base 1 is vertically arranged The second base 2, the base plate 3 is set on the second base 2, the toast box lid 12 is set on the base plate 3, the positioning pin 4 is set on the second base 2, and the positioning hole 5 is set on the base plate 3, so The toast box lid 12 is fixed by the positioning pin 4 and the positioning hole 5, the second base 2 is provided with a limiting orifice hole group, and the first limiting plate 8 and the second limiting plate 9 pass through the limiting orifice. The hole group of the bit hole plate is fixed on the second base 2 .

[0027] Wherein: the second base 2 includes a bottom plate and side plates arranged on both sides of the bottom plate, the limiting orifice hole group includes a first limiting orifice hole 10 and a second limiting orifice ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com