A method for composite hydrophobic coating on activated carbon surface

A technology of hydrophobic coating and surface compounding, which is applied in the direction of separation methods, chemical instruments and methods, carbon compounds, etc., can solve the problems of high energy consumption and degradation of activated carbon regeneration performance, and achieve simple process, enhanced hydrophobicity, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 3g of activated carbon, dip it into 10mL of a mixture of tetraethyl orthosilicate, ethanol, and water with a molar ratio of 1:50:3 at a pH of 1.5, and let it stand at room temperature for 12 hours. Stand at room temperature for 24 hours, add 20mL of n-hexane and let stand for 6h, then filter, replace with new 20mL of n-hexane and let stand for 6h, repeat the replacement 3 times, then filter, immerse in n-hexane solution with a mass concentration of 20% trimethylchlorosilane at room temperature Stand still for 24 hours, filter until apparent dryness, and dry in a blast drying oven at 60°C, 90°C, and 120°C for 2 hours each to obtain hydrophobic activated carbon AC-SiO 2 -20% TMCS.

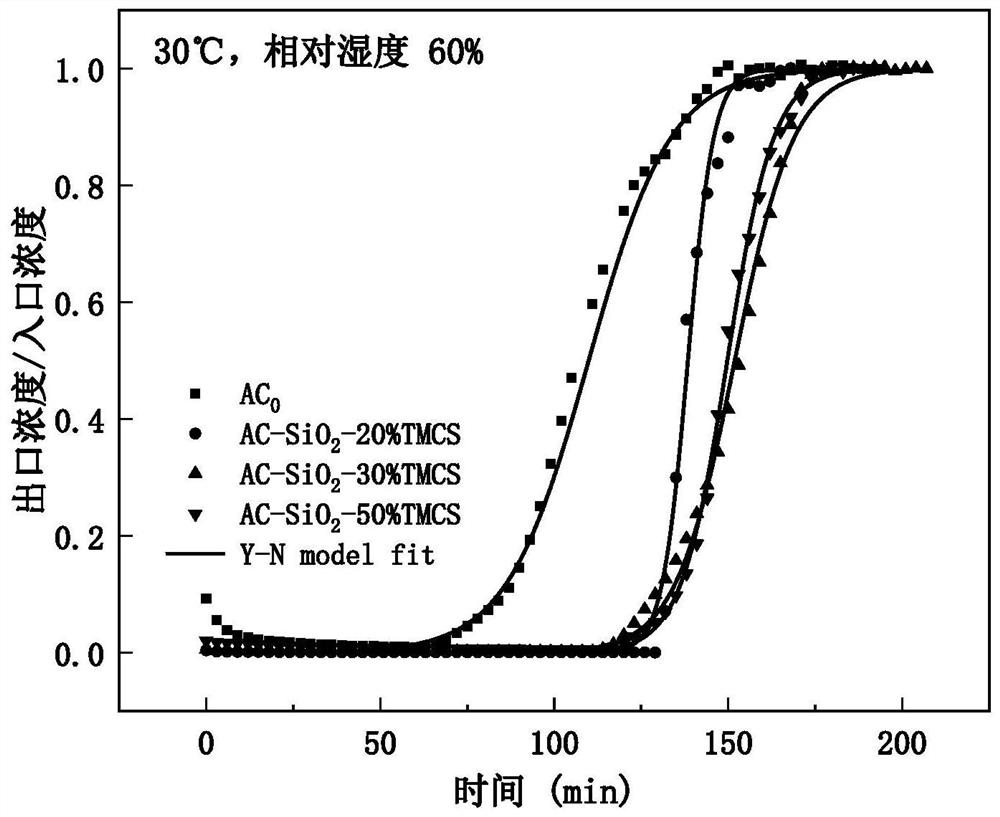

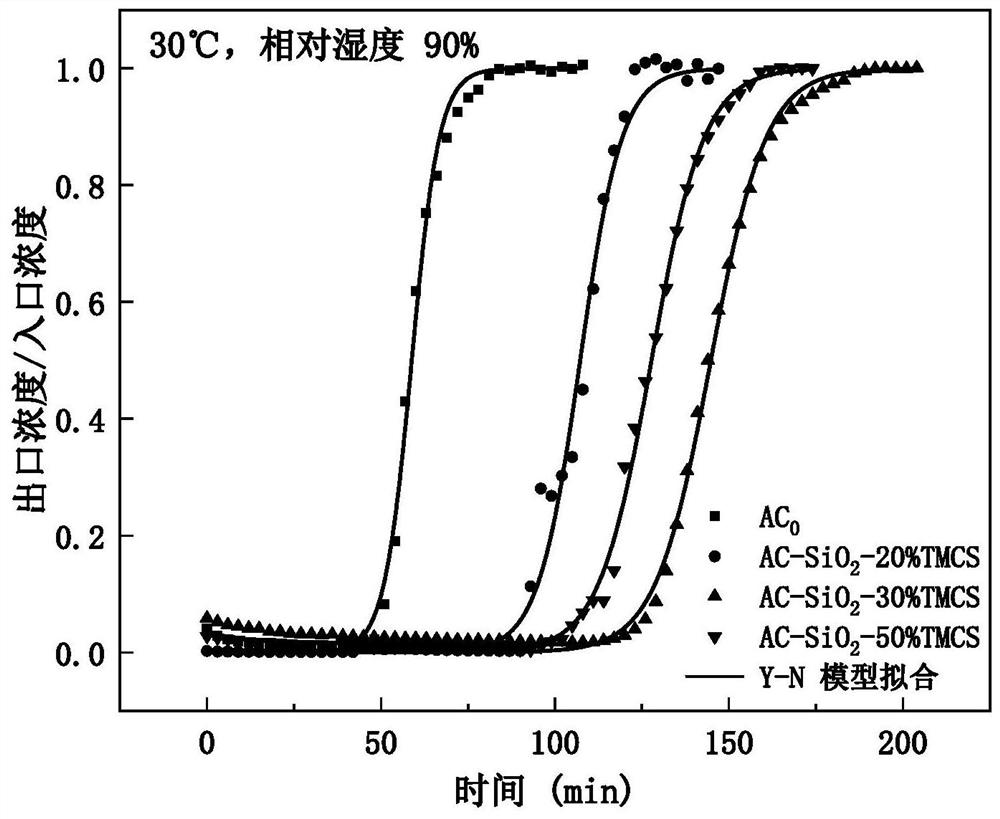

[0024] 0.1g AC-SiO 2 -20% TMCS is placed in the adsorption tube, and the gas phase toluene concentration is 400ppm, the temperature is 30°C, and the relative humidity is 60% of the simulated polluted airflow with a flow rate of 200mL / min. The breakthrough time (outlet concentration reac...

Embodiment 2

[0026] Weigh 3g of activated carbon, dip it into 10mL of a mixture of tetraethyl orthosilicate, ethanol, and water with a molar ratio of 1:50:3 at a pH of 1.5, and let it stand at room temperature for 12 hours. Stand at room temperature for 24 hours, add 20mL of n-hexane and let stand for 6h, then filter, replace with new 20mL of n-hexane and let stand for 6h, repeat the replacement 3 times, then filter, immerse in n-hexane solution with a mass concentration of 30% trimethylchlorosilane at room temperature Stand still for 24 hours, filter until apparent dryness, and dry in a blast drying oven at 60°C, 90°C, and 120°C for 2 hours each to obtain hydrophobic activated carbon AC-SiO 2 -30% TMCS.

[0027] 0.1g AC-SiO 2 -30% TMCS is placed in the adsorption tube, and the gas phase toluene concentration is 400ppm, the temperature is 30°C, and the relative humidity is 60% of the simulated polluted airflow with a flow rate of 200mL / min. The breakthrough time (the outlet concentration ...

Embodiment 3

[0029] Weigh 3g of activated carbon, dip it into 10mL of a mixture of tetraethyl orthosilicate, ethanol, and water with a molar ratio of 1:50:3 at a pH of 1.5, and let it stand at room temperature for 12 hours. Stand at room temperature for 24 hours, add 20mL of n-hexane and let stand for 6h, then filter, replace with new 20mL of n-hexane and let stand for 6h, repeat the replacement 3 times, then filter, immerse in n-hexane solution with a mass concentration of 50% trimethylchlorosilane at room temperature Stand still for 24 hours, filter until apparent dryness, and dry in a blast drying oven at 60°C, 90°C, and 120°C for 2 hours each to obtain hydrophobic activated carbon AC-SiO 2 -50% TMCS.

[0030] 0.1g AC-SiO 2 -50% TMCS is placed in the adsorption tube, and the gas phase toluene concentration is 400ppm, the temperature is 30°C, and the relative humidity is 60% of the simulated polluted airflow with a flow rate of 200mL / min. The breakthrough time (outlet concentration reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com